Exceptional Design Flexibility and Aesthetic Versatility

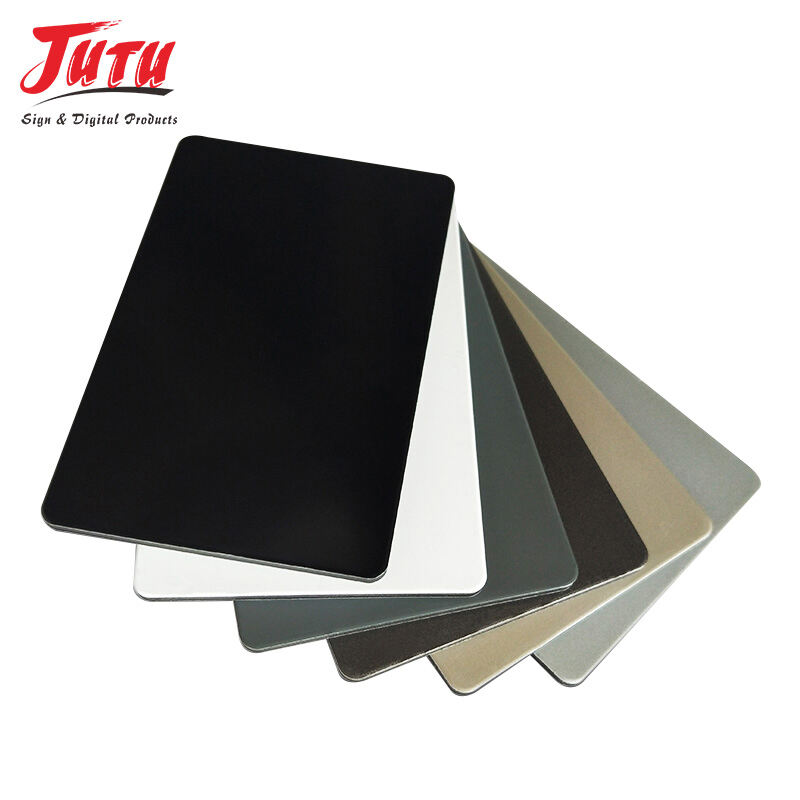

The design flexibility of ACM composite panels empowers architects and designers to realize complex architectural visions while maintaining practical installation and performance requirements. Fabrication capabilities allow for precise cutting, routing, and forming operations that create intricate details, curved surfaces, and three-dimensional architectural elements that enhance building aesthetics and visual impact. CNC machining compatibility enables the production of custom patterns, perforations, and decorative features directly into the panel surface, eliminating the need for secondary operations or additional materials to achieve desired design effects. Bendability characteristics permit the formation of smooth curves and complex geometries without compromising structural integrity, making ACM composite panels ideal for modern architectural styles that emphasize flowing lines and organic shapes. Color matching precision ensures consistent appearance across multiple panel installations, while custom color development services can create unique finishes that match specific design requirements or corporate branding elements. Texture options extend beyond smooth finishes to include wood grain patterns, metallic effects, and brushed surfaces that provide tactile interest and visual depth without sacrificing the practical benefits of aluminum composite construction. Dimensional stability during fabrication prevents warping or distortion during cutting and forming operations, ensuring that finished installations maintain precise alignment and professional appearance. Joint design flexibility accommodates various aesthetic preferences, from minimal reveal joints that create continuous surface effects to pronounced shadow lines that emphasize panel modularity and architectural rhythm. Integration capabilities with other building materials allow ACM composite panels to complement glass, stone, concrete, and other facade elements seamlessly, supporting mixed-material design approaches that create visual interest and architectural sophistication. Surface printing technologies enable the reproduction of photographic images, artistic designs, and complex patterns directly onto ACM composite panels, opening possibilities for feature walls, branding applications, and artistic installations. Panel sizing options accommodate both large-format installations that minimize joint lines and smaller modules that facilitate complex geometric arrangements, providing design teams with maximum creative freedom while maintaining practical installation considerations.