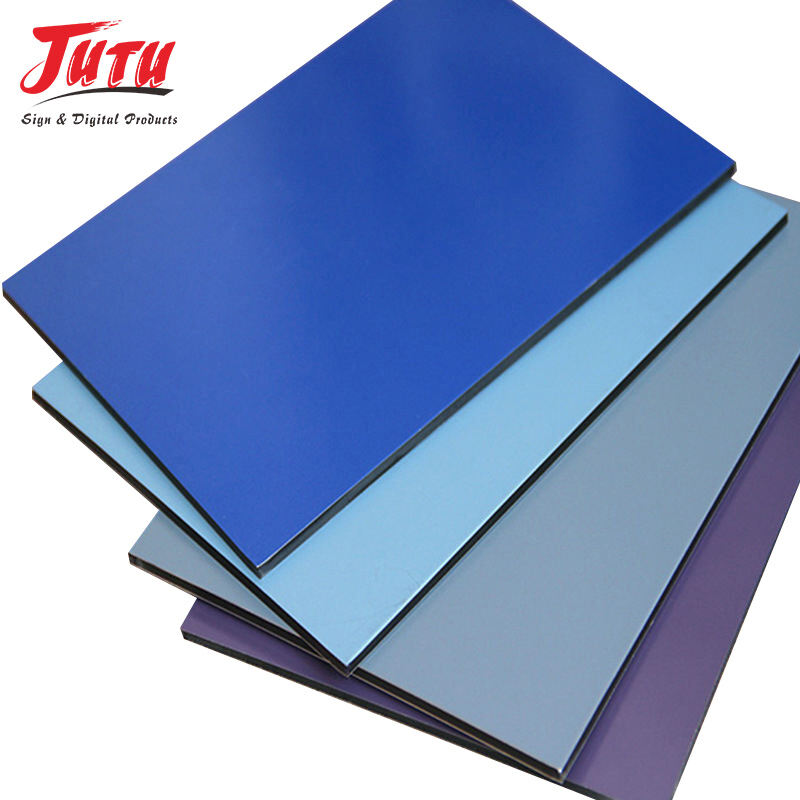

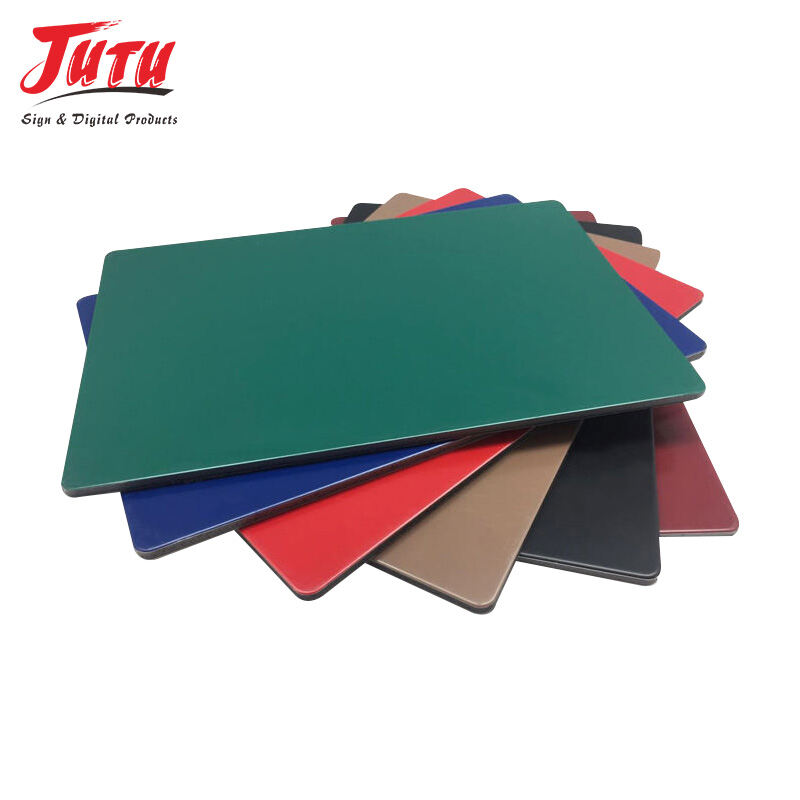

aluminium sandwich sheet

The aluminium sandwich sheet represents a revolutionary construction material that combines lightweight properties with exceptional structural integrity. This innovative building component consists of two thin aluminium sheets bonded to a lightweight core material, typically made from polyethylene, honeycomb, or foam materials. The aluminium sandwich sheet delivers outstanding performance across multiple construction and industrial applications, making it an increasingly popular choice for modern building projects. The core technology behind the aluminium sandwich sheet involves advanced lamination processes that create a composite structure significantly stronger than its individual components. The outer aluminium layers provide weather resistance, corrosion protection, and aesthetic appeal, while the inner core contributes insulation properties and structural stability. This unique configuration allows the aluminium sandwich sheet to maintain rigidity while remaining remarkably lightweight compared to solid metal alternatives. Manufacturing processes for the aluminium sandwich sheet utilize precision engineering to ensure consistent quality and performance standards. The bonding agents used in production create permanent adhesion between layers, eliminating delamination concerns that plague inferior composite materials. Quality control measures throughout production guarantee that each aluminium sandwich sheet meets strict industry specifications for flatness, thickness tolerance, and structural integrity. The versatility of the aluminium sandwich sheet extends across numerous sectors, from architectural cladding to transportation applications. Construction professionals value the material's ability to span large distances without intermediate support structures, reducing installation complexity and labor costs. The thermal properties of the aluminium sandwich sheet contribute to energy-efficient building designs, while its fire-resistant characteristics enhance safety compliance in commercial and residential projects.