Unlimited Design Flexibility and Aesthetic Excellence

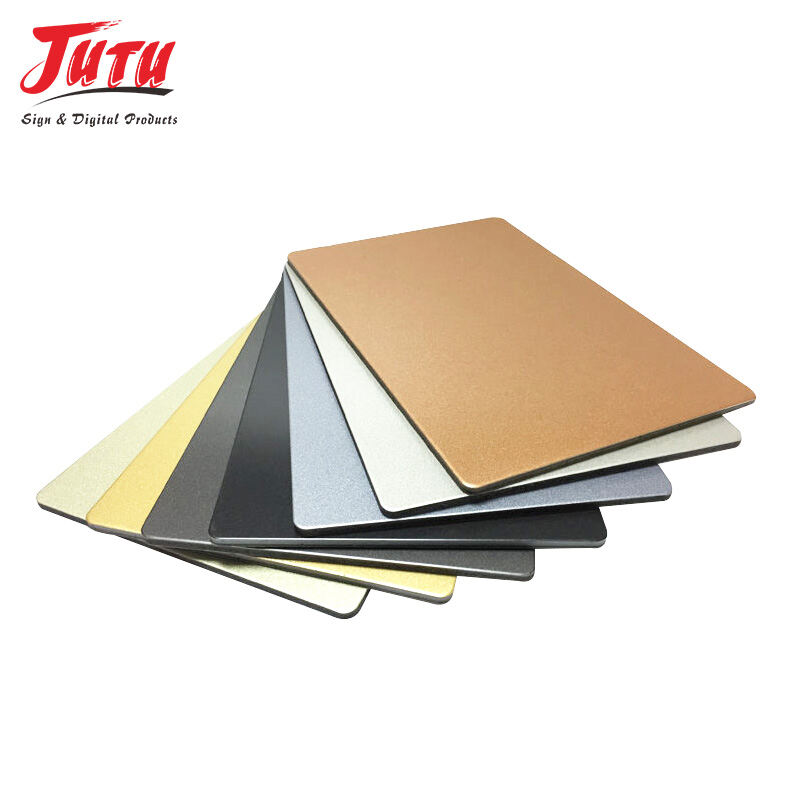

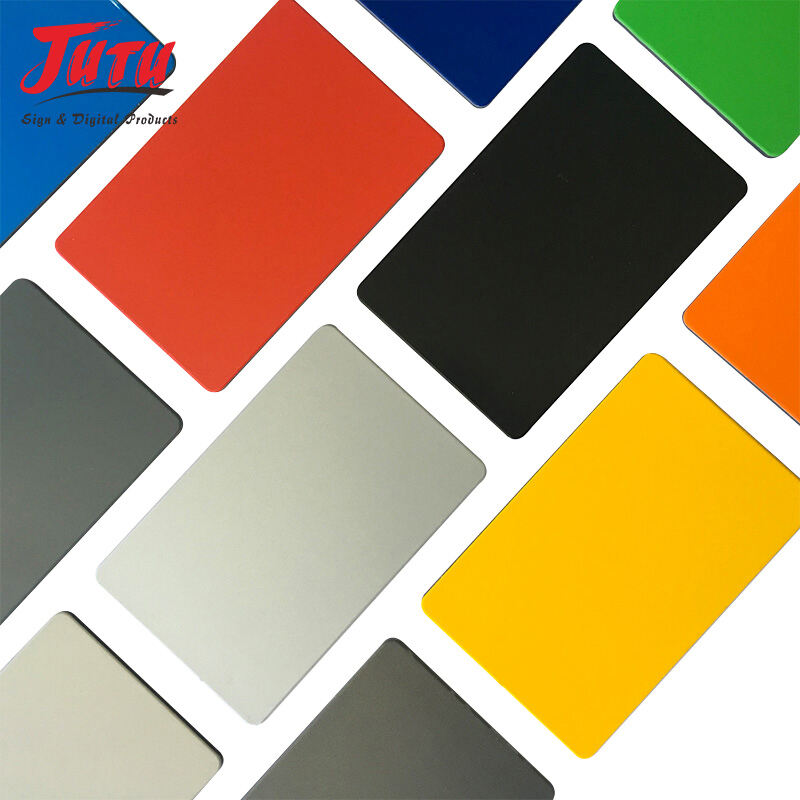

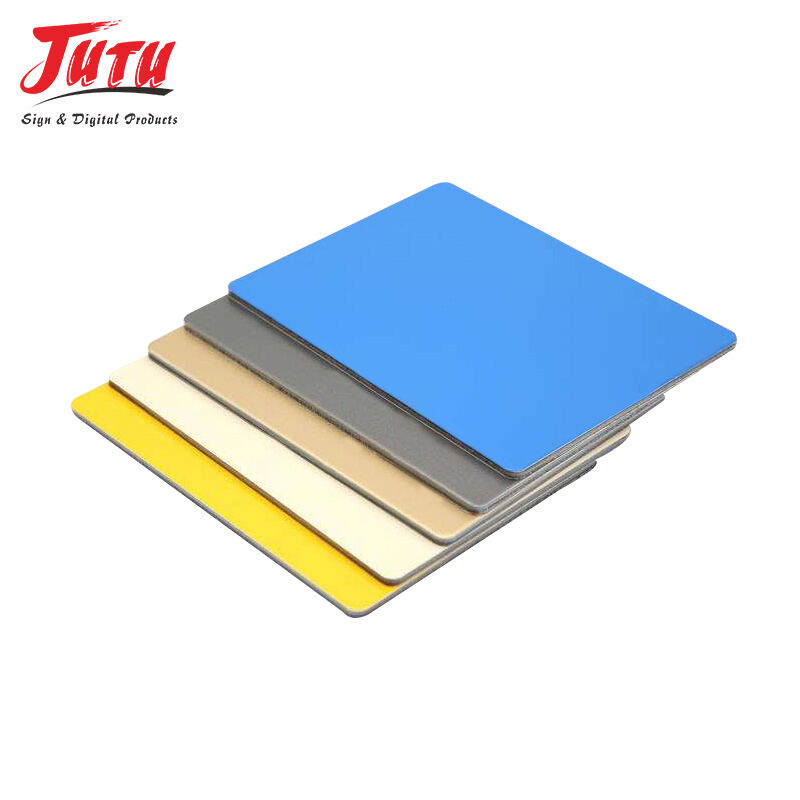

The aluminium composite plate empowers architects and designers with unprecedented creative freedom through extensive customization options and superior workability characteristics. Unlike rigid materials that limit design possibilities, these panels can be shaped, curved, perforated, and finished to achieve virtually any architectural vision. Advanced manufacturing techniques produce custom colors, textures, and surface patterns that replicate natural materials including wood grain, stone textures, and metallic finishes while maintaining the practical benefits of aluminium construction. The material's formability allows complex curved installations that create striking architectural features impossible with traditional cladding systems. Digital printing technologies enable photographic-quality graphics and artistic designs directly applied to panel surfaces, opening new possibilities for branded buildings and artistic expressions. The aluminium composite plate accepts various fabrication techniques including routing, drilling, bending, and cutting to create intricate details and custom configurations. Surface finish options include brushed, mirror, matte, textured, and specialty coatings that respond to specific design requirements and environmental conditions. Color consistency remains stable across large panel installations, ensuring uniform appearance that enhances building aesthetics. The material's compatibility with standard glazing systems creates seamless integration between solid and transparent building elements. Perforation patterns can be customized to provide controlled ventilation, light filtering, and visual screening while maintaining structural performance. Installation flexibility accommodates both concealed and exposed fastening systems depending on aesthetic preferences and technical requirements. The aluminium composite plate easily integrates with LED lighting systems, signage elements, and architectural accents to create dynamic building facades. Quality control processes ensure precise color matching and surface consistency across production batches, enabling confident specification for large-scale projects where aesthetic uniformity is critical for project success and architectural integrity.