Acrylic boards have become indispensable in industries like construction, automotive, and healthcare. Their durability, transparency, and versatility make them a preferred material for diverse applications. Acrylic board manufacturers continue to innovate, addressing evolving market demands. Understanding these advancements is crucial for businesses aiming to stay competitive in this dynamic sector.

Current State of Acrylic Board Manufacturing

Properties and Characteristics

Acrylic boards exhibit a unique combination of properties that make them highly versatile. They are lightweight yet durable, offering excellent resistance to impact and weathering. Their optical clarity rivals that of glass, making them ideal for applications requiring transparency. Additionally, acrylic boards are easy to shape, cut, and mold, allowing manufacturers to create customized solutions for various industries. Their resistance to UV radiation and chemicals further enhances their appeal in outdoor and industrial settings.

Applications Across Industries

Acrylic boards serve a wide range of industries due to their adaptability. In construction, they are used for windows, skylights, and signage. The automotive sector relies on acrylic boards for headlight covers and interior components. In healthcare, they are essential for medical devices, protective barriers, and laboratory equipment. Retail and advertising industries also utilize acrylic boards for displays and point-of-sale materials. This broad spectrum of applications highlights their importance in modern manufacturing.

Emerging Trends Shaping Acrylic Board Manufacturers

Sustainability Initiatives

Sustainability has become a critical focus for acrylic board manufacturers. Companies are adopting eco-friendly practices to reduce their environmental footprint. Many manufacturers now prioritize the use of recycled materials in production. This approach not only conserves resources but also aligns with consumer demand for greener products. Additionally, some manufacturers are exploring bio-based acrylic alternatives derived from renewable sources. These innovations aim to replace petroleum-based components while maintaining the material's durability and clarity. By integrating sustainable practices, manufacturers position themselves as leaders in an increasingly eco-conscious market.

Advanced Manufacturing Technologies

The adoption of advanced technologies is transforming acrylic board production. Automation and robotics streamline manufacturing processes, improving efficiency and reducing errors. Laser cutting and CNC machining enable precise shaping and finishing of acrylic boards. These technologies enhance product quality and reduce material waste. Furthermore, digital twin technology allows manufacturers to simulate production scenarios. This innovation helps identify potential issues before they occur, saving time and resources. Acrylic board manufacturers leveraging these advancements gain a competitive edge in the global market.

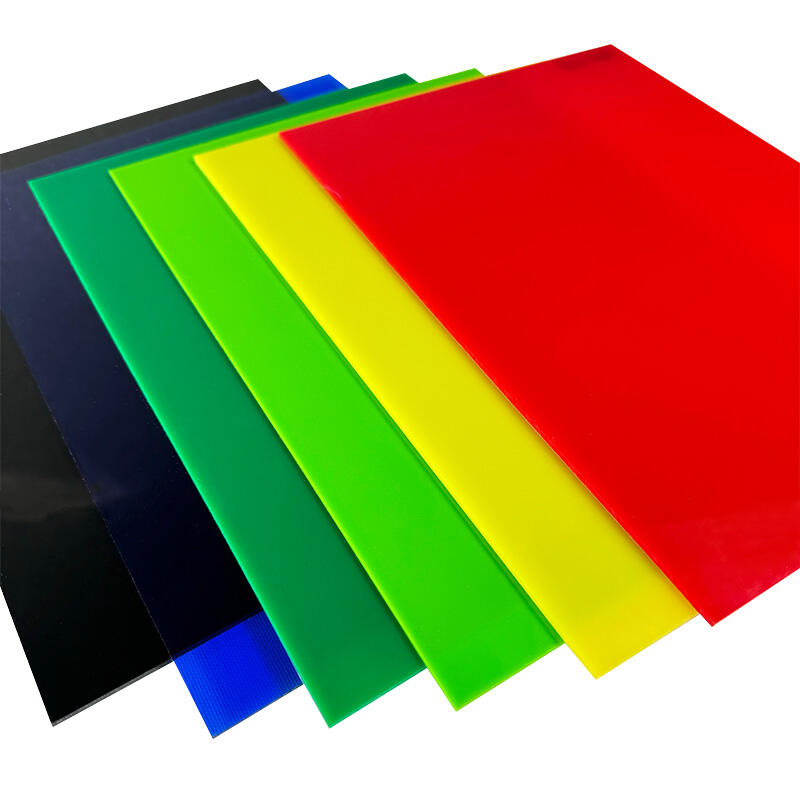

Customization and Design Flexibility

Modern consumers demand products tailored to their specific needs. Acrylic board manufacturers respond by offering greater customization options. Advanced fabrication techniques allow for intricate designs and unique shapes. Manufacturers can now produce boards in various colors, textures, and finishes to meet diverse industry requirements. Customization extends to functional enhancements, such as anti-glare coatings or UV resistance. This flexibility enables manufacturers to cater to niche markets, including luxury retail and high-tech industries. By prioritizing customization, manufacturers enhance customer satisfaction and expand their market reach.

Sustainability and Environmental Impact

Eco-Friendly and Recyclable Materials

The shift toward eco-friendly materials has gained momentum in the acrylic board industry. Manufacturers are increasingly using recyclable acrylic to reduce waste and conserve resources. These materials retain the durability and clarity of traditional acrylic while offering a sustainable alternative. Some companies have also begun experimenting with bio-based acrylic derived from renewable sources like plant-based polymers. This innovation minimizes reliance on petroleum-based components, aligning with global efforts to reduce carbon emissions. By adopting eco-friendly materials, acrylic board manufacturers meet consumer demand for sustainable products and contribute to environmental preservation.

Recycling and Circular Economy Practices

Recycling plays a pivotal role in the sustainability strategies of acrylic board manufacturers. Many companies now implement closed-loop recycling systems, where waste acrylic is collected, processed, and reused in production. This approach reduces landfill contributions and lowers raw material consumption. Additionally, some manufacturers collaborate with recycling facilities to ensure proper disposal and recovery of acrylic products at the end of their lifecycle. These practices support the circular economy model, which emphasizes resource efficiency and waste minimization. By embracing recycling initiatives, manufacturers demonstrate their commitment to sustainable development.

Renewable Energy in Manufacturing

The adoption of renewable energy sources is transforming the manufacturing landscape. Acrylic board manufacturers increasingly rely on solar, wind, and hydroelectric power to operate their facilities. This transition reduces greenhouse gas emissions and lowers energy costs over time. Some companies have also invested in energy-efficient machinery to further minimize their environmental impact. By integrating renewable energy into their operations, manufacturers not only enhance their sustainability credentials but also future-proof their businesses against rising energy prices. These efforts underscore the industry's dedication to reducing its carbon footprint.

Future Applications of Acrylic Boards

Healthcare and Medical Devices

Acrylic boards play a vital role in healthcare due to their durability and clarity. Medical facilities use these boards for protective barriers, such as sneeze guards and partitions, ensuring hygiene and safety. Their lightweight nature makes them ideal for medical device components, including incubators and surgical equipment. Acrylic boards also serve as display panels for diagnostic machines, offering excellent optical clarity. Their resistance to chemicals ensures they remain unaffected by frequent cleaning with disinfectants. As healthcare technology advances, the demand for acrylic boards in innovative medical applications continues to grow.

Automotive and Transportation

The automotive and transportation industries rely heavily on acrylic boards for their strength and versatility. These boards are commonly used in vehicle interiors, such as dashboards and instrument panels, due to their lightweight properties. Headlight covers made from acrylic provide excellent transparency and impact resistance. Public transportation systems also utilize acrylic boards for protective screens and signage. Their ability to withstand harsh weather conditions makes them suitable for exterior applications. As electric vehicles and autonomous transportation systems evolve, acrylic boards will likely find new uses in futuristic designs and components.

Construction and Architecture

Acrylic boards have become a staple in modern construction and architecture. Architects use them for skylights, windows, and decorative panels due to their transparency and UV resistance. These boards are also popular in interior design for partitions, furniture, and lighting fixtures. Their ability to mimic glass while being more durable and lightweight makes them a preferred choice for both residential and commercial projects. Acrylic boards contribute to energy-efficient designs by allowing natural light to pass through while providing insulation. As sustainable building practices gain traction, acrylic boards will play a key role in innovative architectural solutions.

Acrylic board manufacturing continues to evolve through groundbreaking innovations, sustainability initiatives, and advanced technologies. These trends redefine industry standards while addressing environmental concerns. Manufacturers adopting these advancements position themselves as leaders in the plastics industry. Acrylic boards hold transformative potential, offering versatile solutions that meet modern demands and shape the future of material science. ?