aluminum composite metal panels

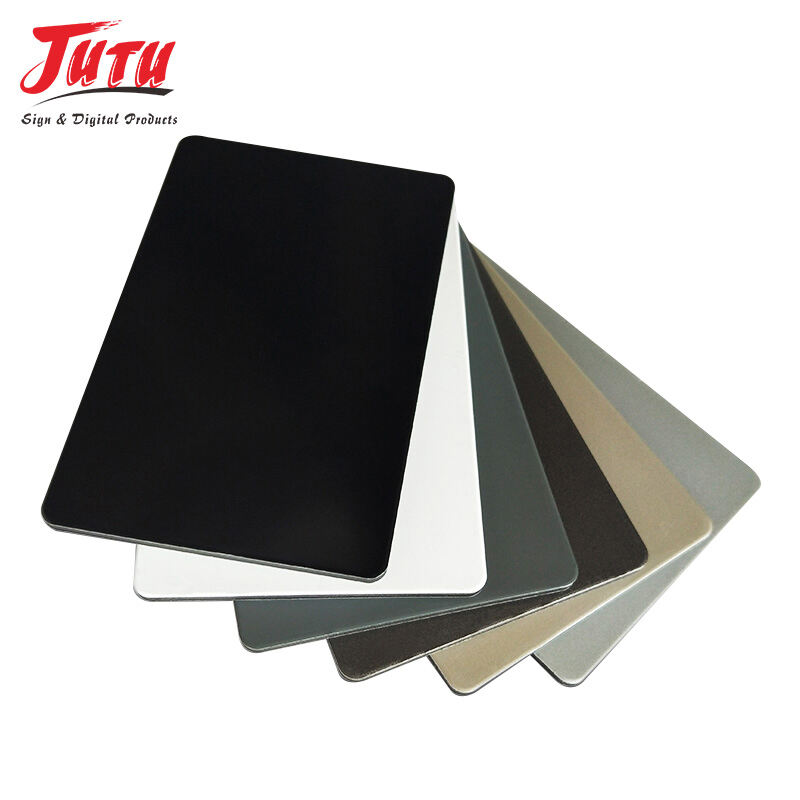

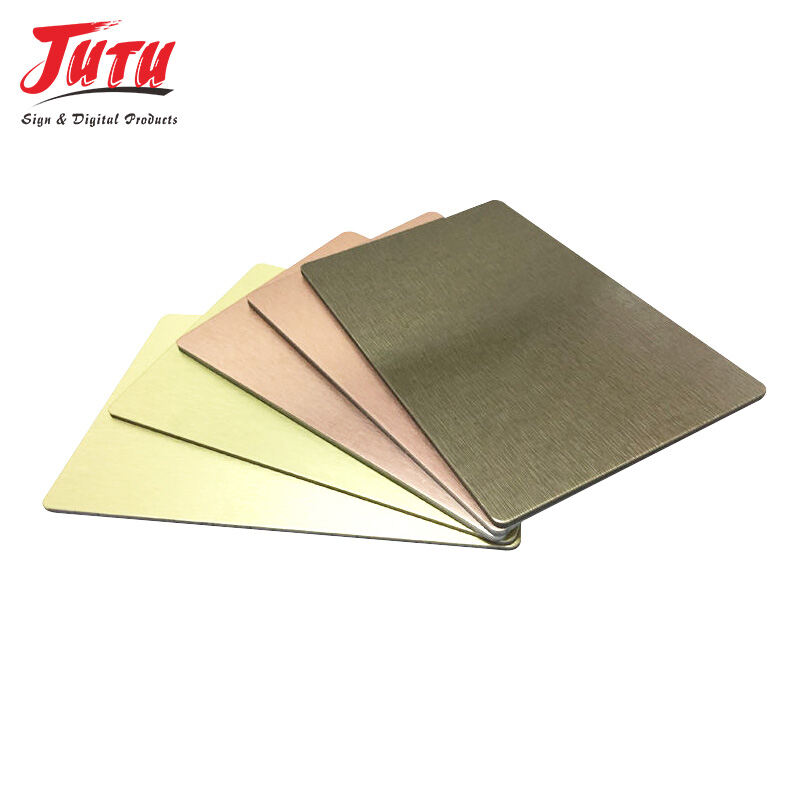

Aluminum composite metal panels represent a revolutionary building material that combines the lightweight properties of aluminum with enhanced structural integrity through advanced composite technology. These panels consist of two thin aluminum sheets bonded to a non-aluminum core, typically made from polyethylene or mineral-filled materials, creating a sandwich structure that delivers exceptional performance across multiple construction applications. The main functions of aluminum composite metal panels include providing superior weather protection, thermal insulation, and aesthetic enhancement for both interior and exterior architectural projects. These panels excel in moisture resistance, preventing water infiltration that could compromise building integrity over time. Their technological features encompass advanced surface treatments that resist corrosion, UV degradation, and environmental pollutants, ensuring long-lasting color retention and structural stability. The manufacturing process involves precision bonding techniques that create seamless integration between the aluminum faces and core materials, resulting in panels that maintain dimensional stability under varying temperature conditions. Applications for aluminum composite metal panels span across commercial construction, residential renovation projects, industrial facilities, and specialized architectural installations. These panels prove particularly valuable in curtain wall systems, building facades, interior partitions, and decorative cladding applications. The versatility of aluminum composite metal panels extends to signage applications, where their flat surface and paintability make them ideal for corporate branding and architectural signage solutions. Modern manufacturing techniques enable customization in terms of thickness, color, texture, and surface finishes, allowing architects and designers to achieve specific aesthetic goals while maintaining structural requirements. The panels demonstrate excellent workability, accepting standard metalworking tools for cutting, drilling, and forming operations, which simplifies installation processes and reduces labor costs. Fire-resistant variants of aluminum composite metal panels incorporate mineral-based cores that enhance safety performance in high-rise construction and public buildings where fire safety regulations demand superior materials.