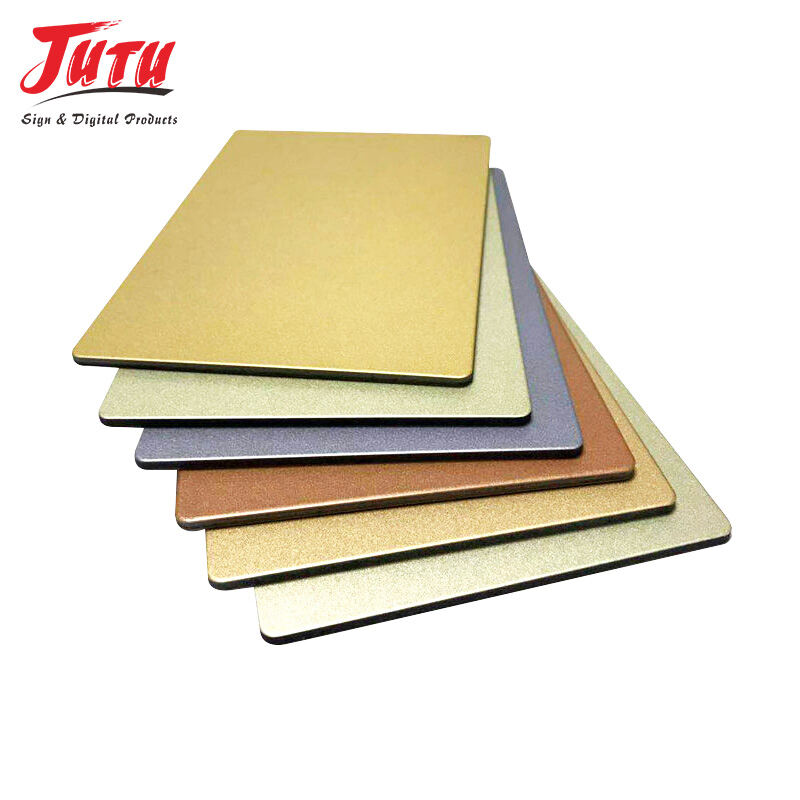

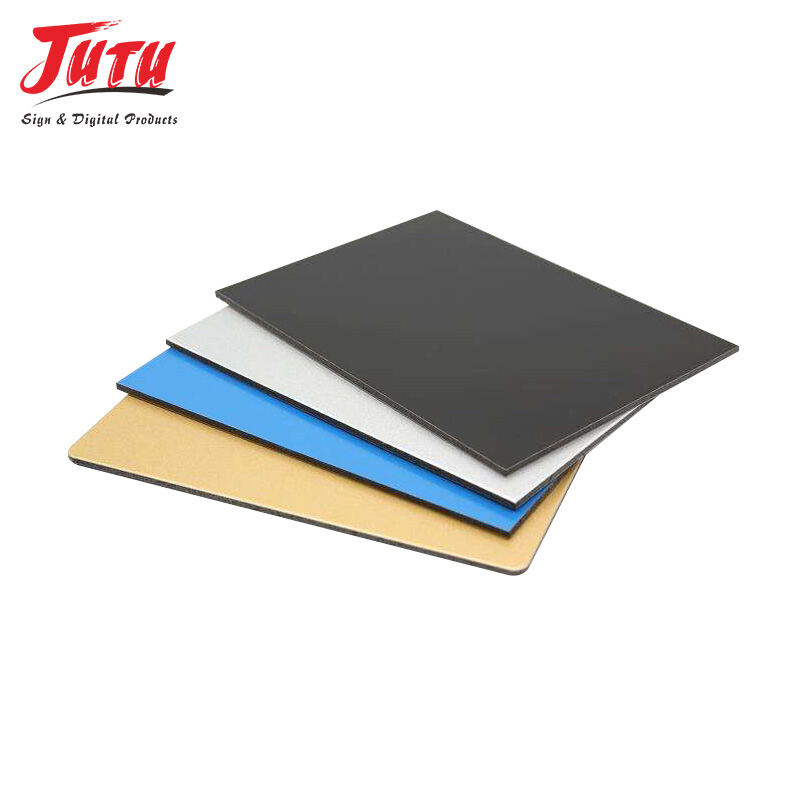

signage aluminum composite panel

Signage aluminum composite panel represents a revolutionary building material specifically engineered for modern advertising and architectural applications. This innovative material consists of two thin aluminum sheets bonded to a non-aluminum core, typically made from polyethylene or mineral-filled materials. The signage aluminum composite panel delivers exceptional performance through its unique three-layer construction, providing businesses and architects with a versatile solution for exterior and interior signage projects. The primary functions of signage aluminum composite panel include weather resistance, structural stability, and aesthetic enhancement. These panels excel in outdoor environments where traditional materials often fail due to harsh weather conditions, UV exposure, and temperature fluctuations. The technological features of signage aluminum composite panel incorporate advanced bonding techniques that ensure long-term adhesion between layers, preventing delamination and maintaining structural integrity. The aluminum faces undergo specialized surface treatments, including anodizing or coating processes, which enhance corrosion resistance and provide superior paint adhesion. Manufacturing processes utilize precision rolling and laminating technologies to achieve consistent thickness and flatness across the entire panel surface. Quality control measures ensure that each signage aluminum composite panel meets strict dimensional tolerances and performance standards. Applications for signage aluminum composite panel span across multiple industries including retail, hospitality, healthcare, education, and commercial real estate. These panels serve as ideal substrates for channel letters, cabinet signs, monument signs, and large-format graphics. Interior applications include wall cladding, ceiling systems, and decorative elements where lightweight yet durable materials are essential. The versatility of signage aluminum composite panel extends to custom fabrication possibilities, allowing designers to create complex shapes, curves, and angular configurations that meet specific project requirements.