Exceptional Design Flexibility and Aesthetic Versatility

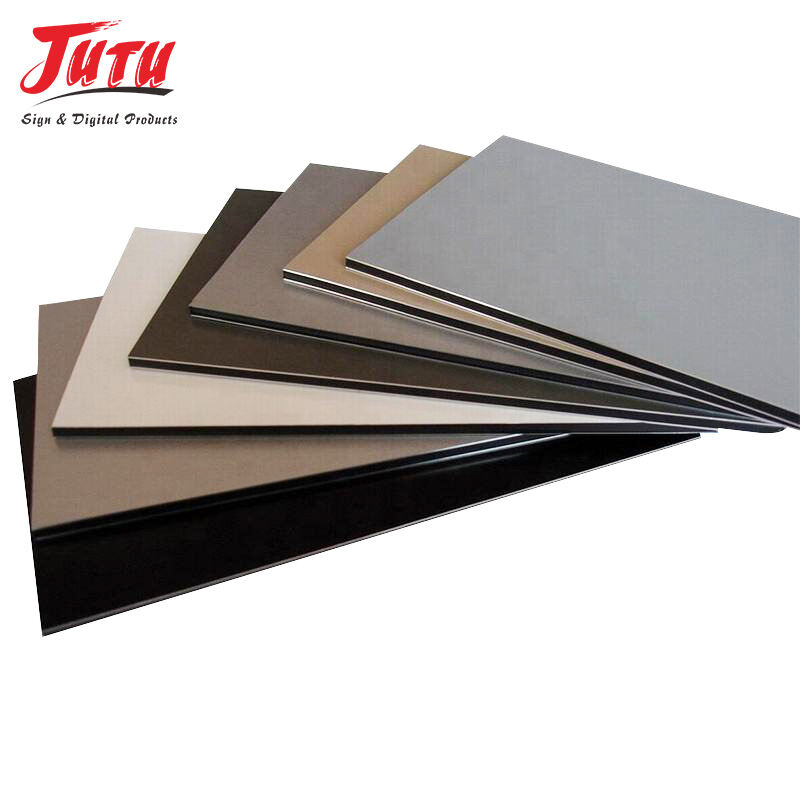

The design capabilities of alucobond ACM panels surpass traditional cladding materials through advanced fabrication techniques that enable architects to realize complex geometric visions while maintaining structural performance and cost efficiency. The panels accept precise cutting, forming, and shaping operations that create smooth curves, sharp angles, and intricate architectural details impossible to achieve with conventional materials. Computer-controlled fabrication equipment ensures dimensional accuracy within tight tolerances, enabling seamless integration of panel elements regardless of design complexity. The lightweight construction allows for cantilever installations and dramatic overhangs that would require prohibitive structural support with heavier cladding systems. Surface treatment options include brushed finishes that create subtle texture variations, perforated patterns that provide controlled transparency effects, and embossed textures that add dimensional interest to facade surfaces. Color matching capabilities utilize advanced spectral analysis to ensure perfect coordination with existing building elements or corporate branding requirements. Custom printing processes can reproduce complex graphics, photographic images, or architectural patterns directly onto the panel surface, creating unique visual effects that transform buildings into artistic statements. The modular design system facilitates both regular grid patterns and irregular compositions, allowing designers to create rhythm and visual movement across large facade areas. Panel joining methods include concealed fastening systems that create smooth, uninterrupted surfaces, and reveal joint systems that emphasize panel geometry and create shadow effects. The ability to combine different finishes, colors, and textures within a single installation provides unlimited creative possibilities for architectural expression. Renovation applications benefit from the ability to apply alucobond ACM panels directly over existing facades, transforming dated buildings without extensive structural modifications. The panels integrate seamlessly with other building systems including glazing, louvers, and mechanical equipment, maintaining design continuity across diverse functional elements. Installation flexibility accommodates both vertical and horizontal orientations, curved transitions, and compound angles that follow complex building geometries while maintaining weather-tight performance.