Unmatched Versatility for Diverse Applications

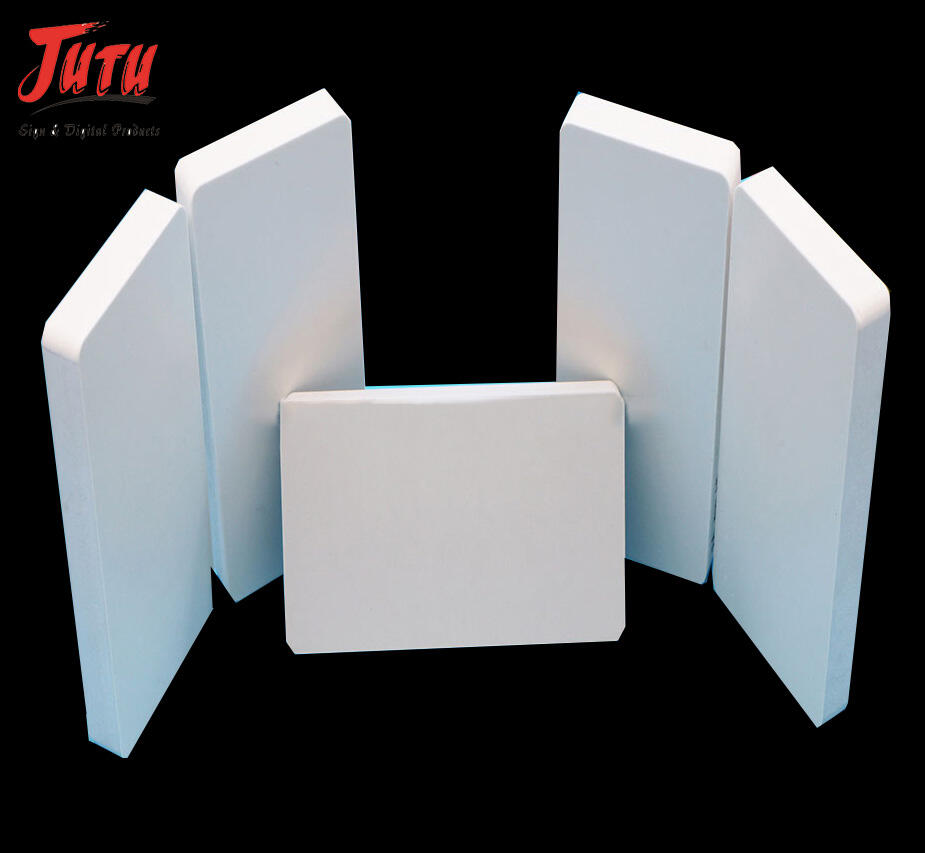

The exceptional versatility of pvc co extruded foam board makes it an ideal solution for an extensive range of applications across multiple industries, from construction and signage to marine and transportation sectors. This adaptability stems from its unique combination of properties that simultaneously address multiple performance requirements typically found only in specialized materials. In construction applications, the pvc co extruded foam board serves as excellent wall cladding, roofing substrate, and insulation component, providing thermal barrier properties while maintaining structural integrity under various load conditions. Its lightweight nature significantly reduces the structural load on buildings, allowing for more economical foundation and framing systems while maintaining required performance standards. The material's compatibility with standard construction tools and techniques enables seamless integration into existing workflows without requiring specialized training or equipment investments. For signage and display applications, the smooth surface accepts various printing methods, including digital printing, screen printing, and vinyl application, while the rigid structure maintains flat, professional appearance even in large format installations. The pvc co extruded foam board excels in marine environments where traditional materials fail due to moisture, salt spray, and UV exposure, maintaining structural integrity and appearance for extended periods without protective treatments. Transportation applications benefit from the material's lightweight properties, which help improve fuel efficiency while providing durable surfaces for interior panels, flooring, and component mounting substrates. The board's fire retardant properties make it suitable for applications requiring compliance with strict safety regulations, including commercial buildings, transportation vehicles, and industrial facilities. Its chemical resistance enables use in laboratories, manufacturing facilities, and food processing environments where exposure to aggressive substances could damage conventional materials. The pvc co extruded foam board can be thermoformed, allowing creation of complex three-dimensional shapes for specialized applications while maintaining its structural properties. This formability opens opportunities in industries such as aerospace, automotive, and recreational vehicle manufacturing where lightweight, durable components are essential. Environmental resistance ensures reliable outdoor performance without degradation, making it suitable for architectural elements, recreational structures, and landscape applications that require long-term durability.