wpc pvc board

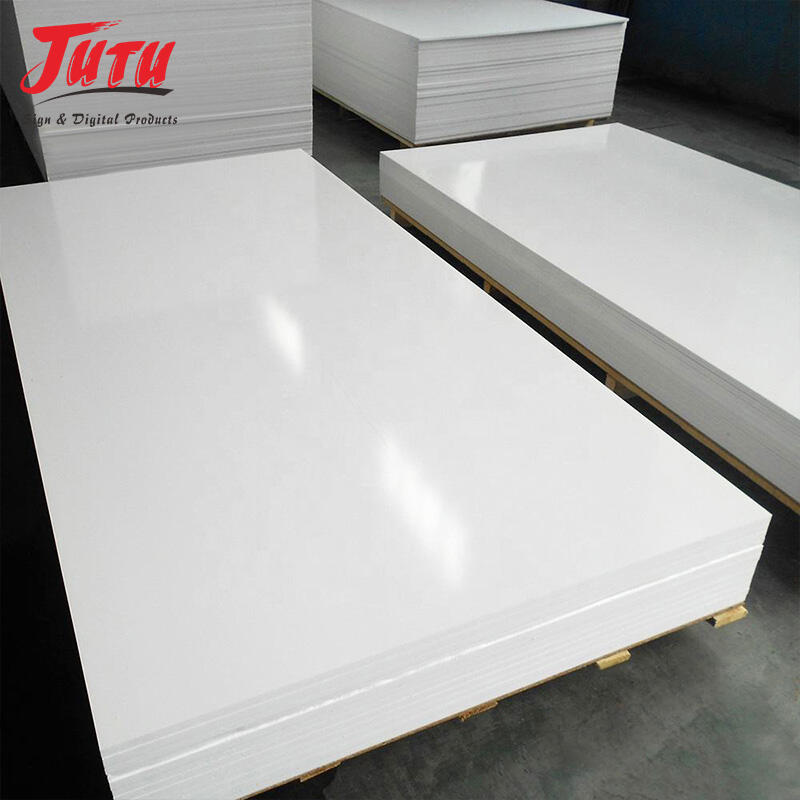

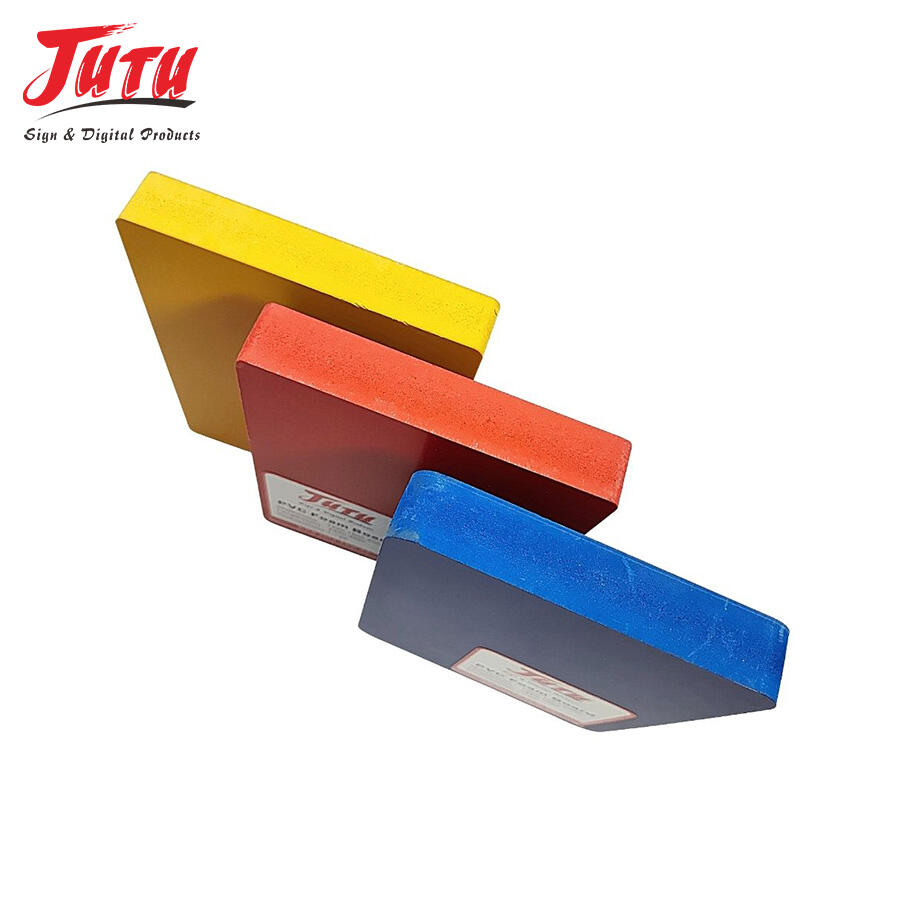

WPC PVC board represents a revolutionary building material that combines the best properties of wood plastic composite technology with polyvinyl chloride engineering. This innovative construction solution offers exceptional durability and versatility for both residential and commercial applications. The WPC PVC board manufacturing process involves blending recycled wood fibers with high-grade PVC resin, creating a composite material that surpasses traditional building materials in performance and longevity. The technological features of WPC PVC board include advanced moisture resistance, dimensional stability, and enhanced structural integrity. These boards maintain consistent performance across varying environmental conditions, making them ideal for outdoor installations, bathroom renovations, and commercial construction projects. The main functions of WPC PVC board encompass structural support, decorative finishing, and protective sheathing applications. Construction professionals choose WPC PVC board for its exceptional workability, allowing standard woodworking tools to cut, drill, and install these panels efficiently. The surface texture of WPC PVC board can be customized to mimic natural wood grain, smooth finishes, or embossed patterns, providing designers with extensive creative flexibility. Applications for WPC PVC board span across residential siding, commercial cladding, interior wall panels, bathroom installations, and outdoor decking projects. The material demonstrates superior fire resistance compared to traditional wood products, meeting stringent building codes and safety requirements. WPC PVC board installation requires minimal maintenance while delivering long-term aesthetic appeal and structural performance. Environmental sustainability remains a key consideration, as WPC PVC board manufacturing utilizes recycled materials, reducing waste and supporting green building initiatives. The thermal properties of WPC PVC board provide excellent insulation characteristics, contributing to energy efficiency in building envelopes.