lowes pvc foam board

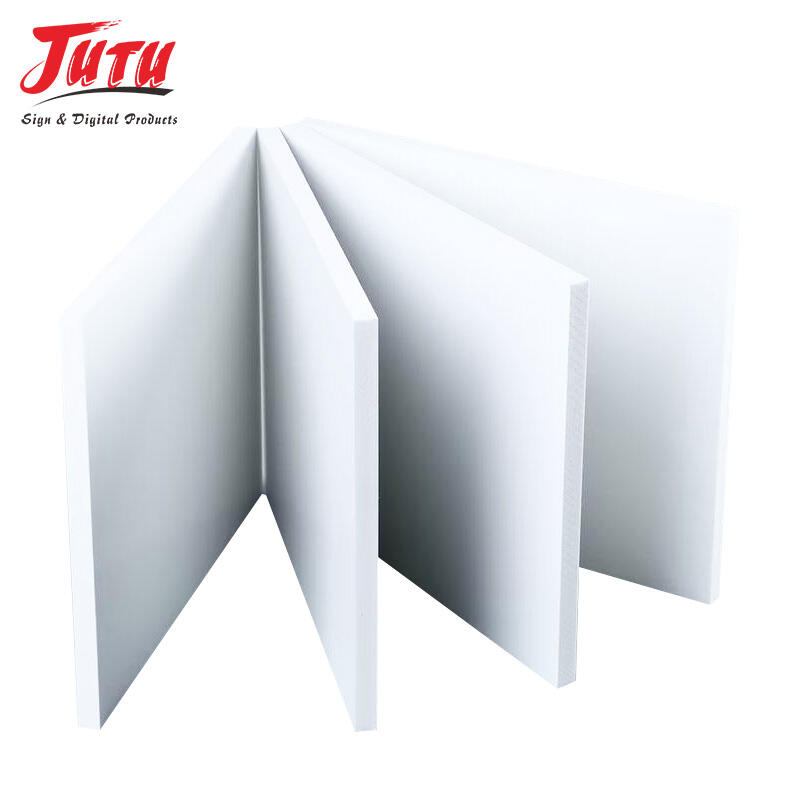

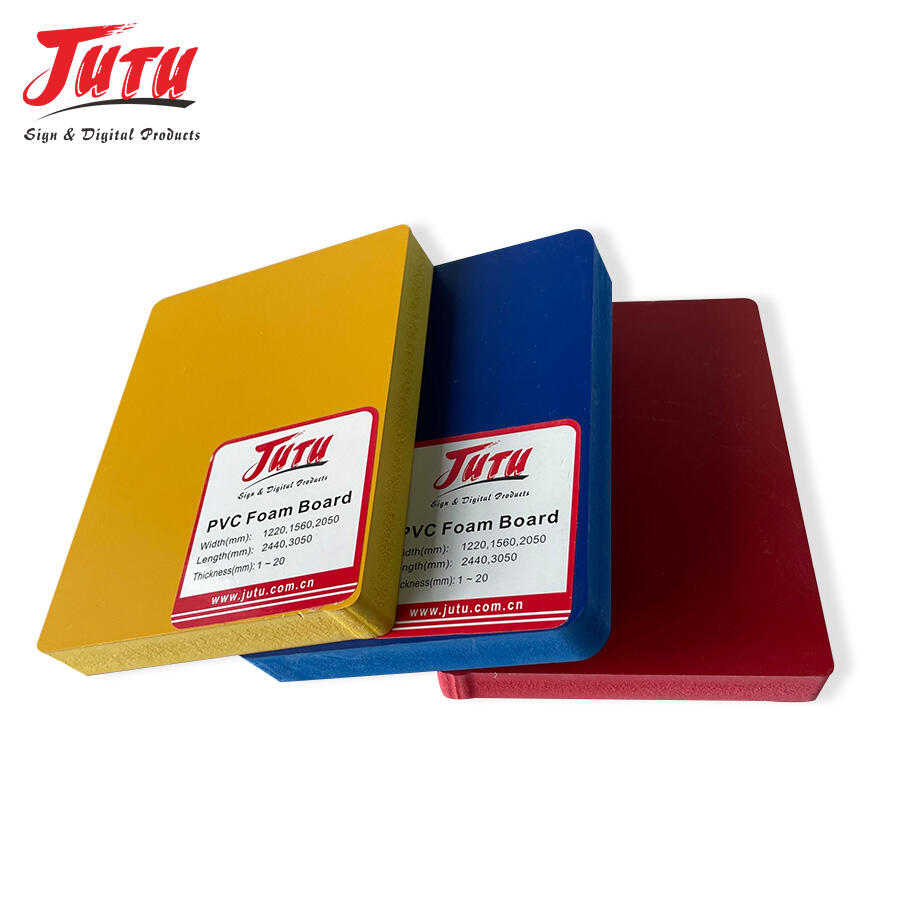

The Lowes PVC foam board stands as a revolutionary building material that combines exceptional versatility with outstanding performance characteristics. This innovative product represents a significant advancement in construction and fabrication materials, offering users a lightweight yet durable solution for countless applications. The Lowes PVC foam board features a closed-cell foam core structure that delivers remarkable strength-to-weight ratios while maintaining excellent dimensional stability under varying environmental conditions. This advanced material incorporates cutting-edge manufacturing processes that ensure consistent quality and reliable performance across all applications. The technological foundation of the Lowes PVC foam board relies on premium-grade polyvinyl chloride resins that undergo specialized foaming processes to create uniform cell structures throughout the material. This sophisticated manufacturing approach results in boards that exhibit superior flatness, smooth surface finishes, and exceptional machinability. The material maintains its structural integrity across temperature fluctuations and resists warping, shrinking, or expanding that commonly affects traditional building materials. Applications for the Lowes PVC foam board span numerous industries and project types, from commercial construction to residential improvements and specialized fabrication work. Contractors frequently utilize this material for exterior siding applications, trim work, and architectural details where weather resistance proves crucial. The board excels in marine environments due to its moisture resistance properties, making it ideal for boat building, dock construction, and waterfront structures. Indoor applications include cabinet construction, furniture manufacturing, display fabrication, and partition systems. The material processes easily with standard woodworking tools, allowing for precise cuts, routing, and shaping operations. Paint adhesion qualities enable seamless finishing with various coating systems, while the smooth surface eliminates the need for extensive preparation work typically required with other materials.