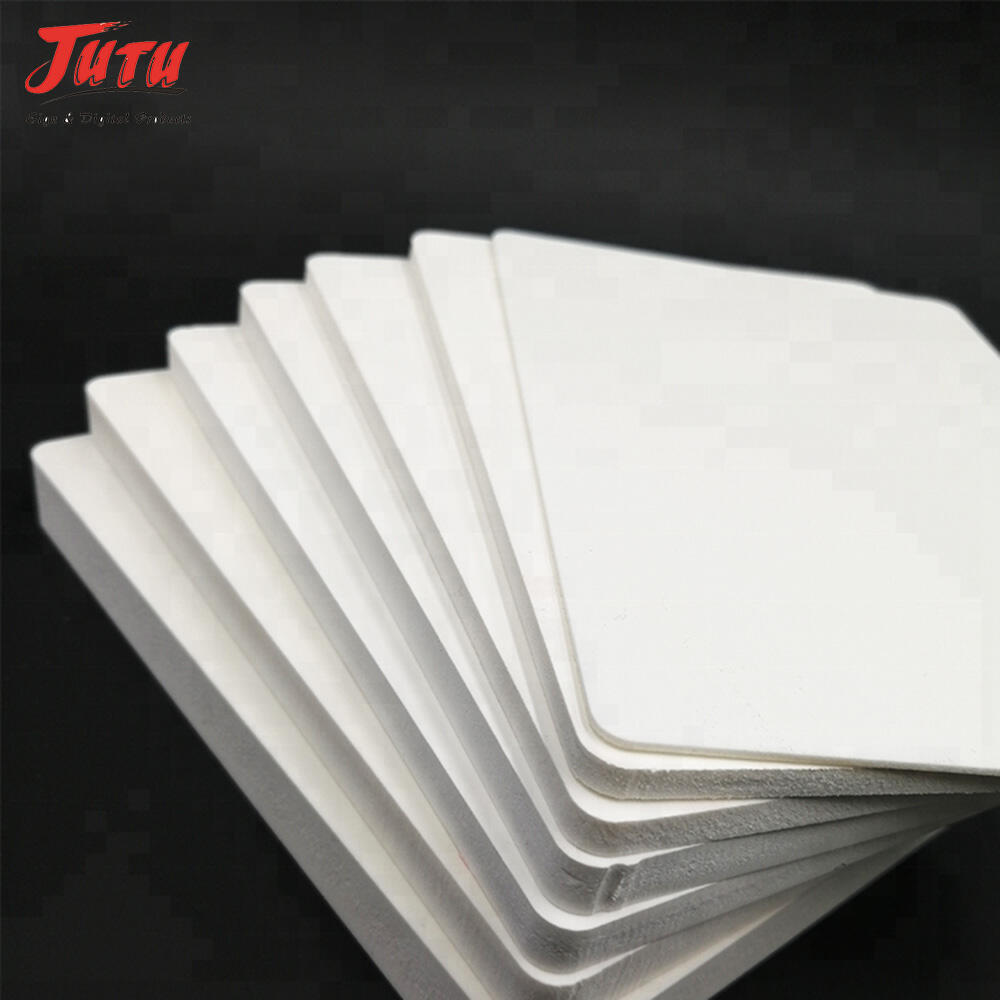

pvc foam board sheet

PVC foam board sheet represents a revolutionary building material that combines lightweight construction with exceptional durability and versatility. This innovative material consists of a rigid polyvinyl chloride foam core sandwiched between smooth, non-porous surfaces, creating a uniform cellular structure that delivers outstanding performance across multiple applications. The manufacturing process involves precise temperature control and chemical foaming agents that produce consistent cell formation throughout the pvc foam board sheet, ensuring reliable mechanical properties and dimensional stability. The main functions of pvc foam board sheet include structural support, insulation, waterproofing, and decorative applications in both interior and exterior environments. Its closed-cell foam structure provides excellent thermal insulation properties while maintaining structural integrity under various load conditions. The technological features of pvc foam board sheet encompass superior chemical resistance, UV stability, and flame retardant characteristics that meet stringent building codes and safety standards. Advanced extrusion technology ensures uniform density distribution and smooth surface finish, making it suitable for high-precision applications requiring tight tolerances. The material exhibits exceptional workability, allowing for easy cutting, drilling, routing, and shaping using standard woodworking tools without specialized equipment. Applications for pvc foam board sheet span across construction, signage, marine, automotive, and furniture industries. In construction projects, it serves as cladding material, partition walls, ceiling panels, and decorative elements. The signage industry utilizes pvc foam board sheet for outdoor advertising displays, exhibition stands, and point-of-sale materials due to its excellent printability and weather resistance. Marine applications include boat interiors, deck components, and structural elements where moisture resistance and lightweight properties are crucial. The automotive sector employs pvc foam board sheet for interior trim, dashboard components, and insulation panels. Furniture manufacturers appreciate its versatility for creating modern designs, cabinet doors, and decorative panels that require both aesthetics and functionality.