Design Flexibility and Aesthetic Excellence

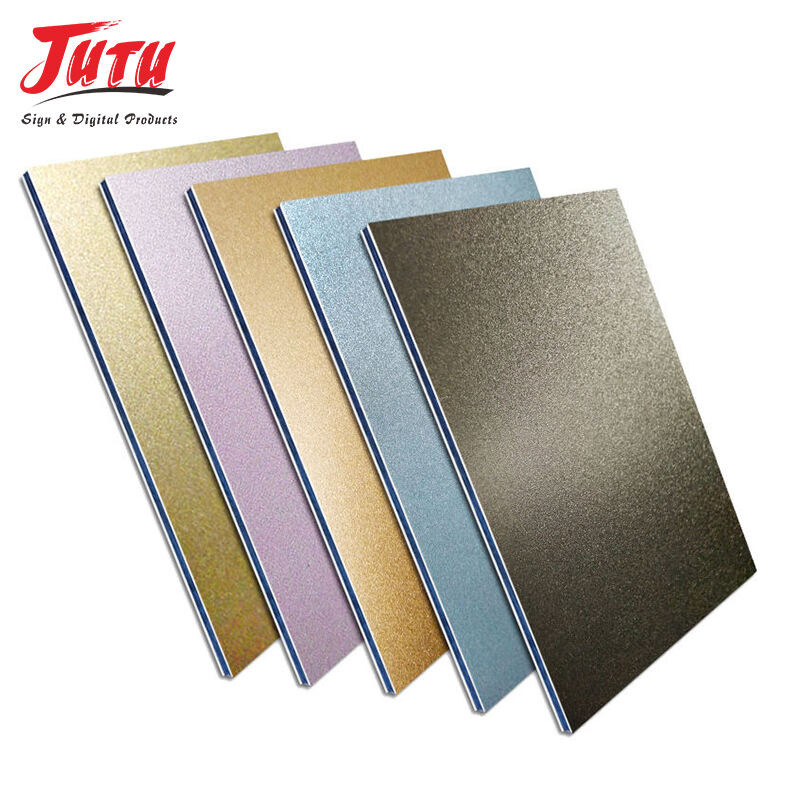

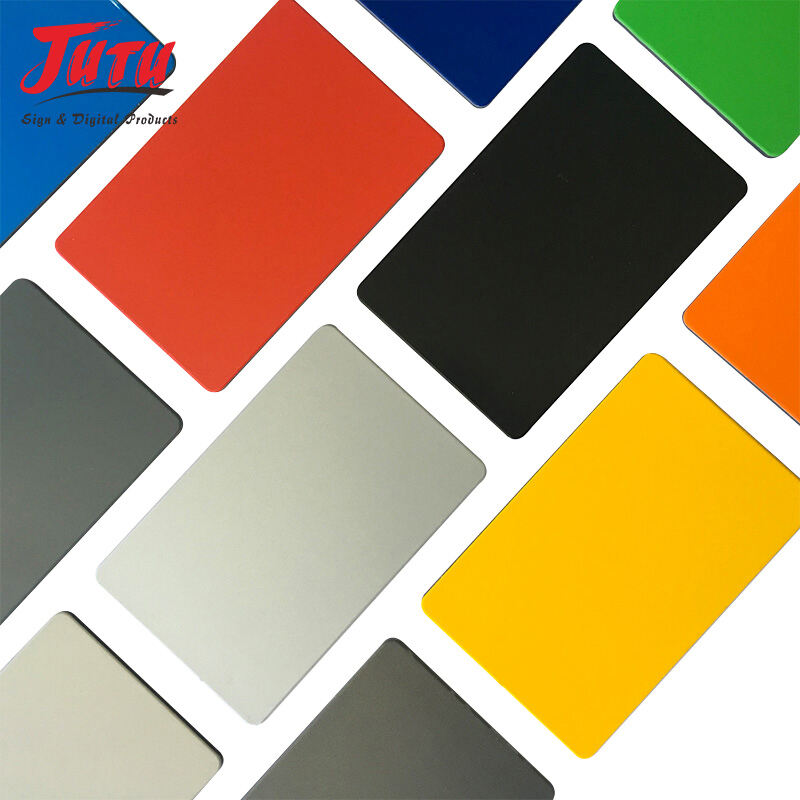

The exceptional design flexibility of PVDF aluminum composite panel empowers architects to create stunning facades that combine aesthetic appeal with practical performance advantages. Available in an extensive range of colors, textures, and finishes including metallic, wood grain, stone, and solid colors, these panels enable unlimited creative expression while maintaining consistent quality and durability. The manufacturing process allows for custom color matching to meet specific design requirements, ensuring perfect coordination with other building materials and architectural elements. Advanced digital printing technology enables realistic reproduction of natural materials like marble, granite, and exotic woods without the weight, cost, and maintenance challenges associated with genuine materials. The smooth surface finish of PVDF aluminum composite panel provides excellent substrate for various decorative treatments including perforation, embossing, and custom patterns that create unique visual effects and shadow play on building facades. Fabrication flexibility allows for complex curved surfaces and three-dimensional forms that would be difficult or impossible to achieve with traditional rigid materials. The lightweight construction enables installation of large panel sizes that create seamless appearances with minimal visible joints, contributing to clean modern aesthetics preferred in contemporary architecture. Color consistency remains uniform across entire installations due to controlled manufacturing processes that eliminate variations common in field-applied coatings. The aesthetic excellence of PVDF aluminum composite panel extends to long-term appearance retention, with colors remaining vibrant and surfaces maintaining their original finish quality for decades. Maintenance of aesthetic appeal requires only routine cleaning with mild detergents, avoiding the need for specialized treatments or refinishing that other materials may require. The design possibilities extend to integration with building systems including lighting, signage, and mechanical equipment that can be seamlessly incorporated into panel designs for cohesive architectural solutions.