composite metal wall panel

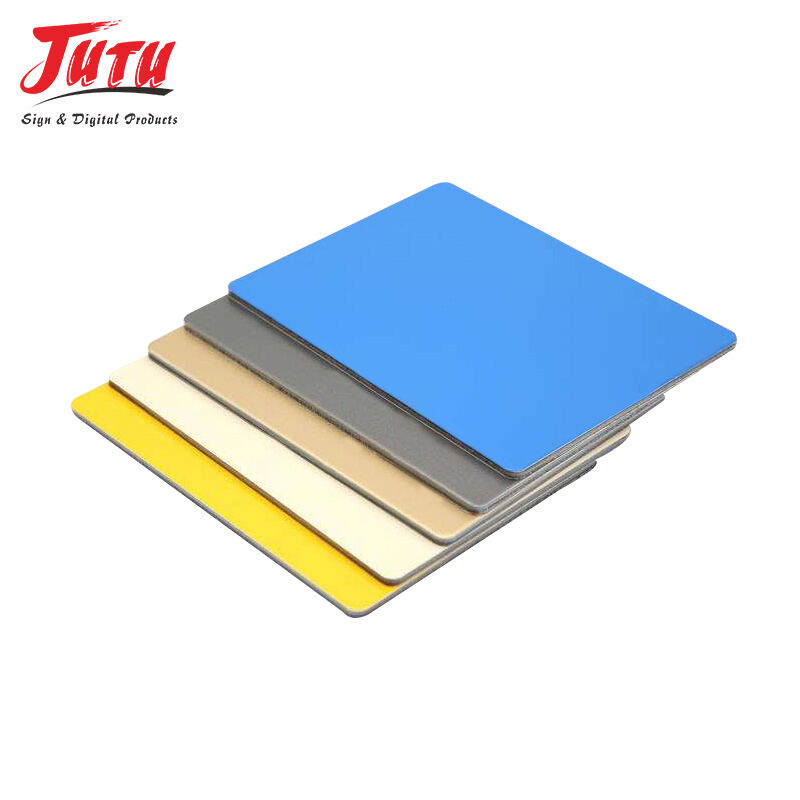

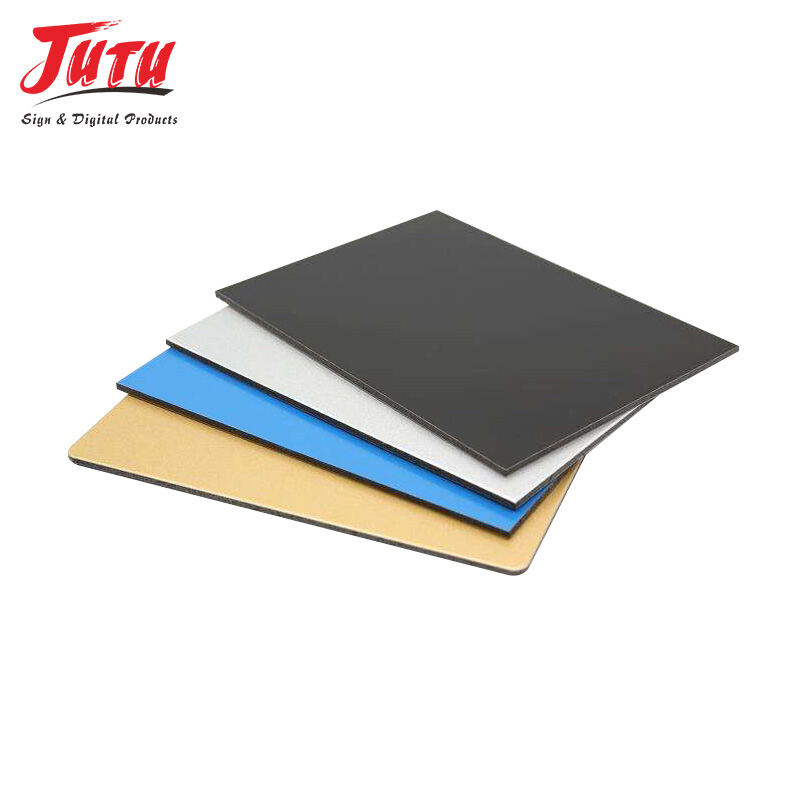

Composite metal wall panels represent a revolutionary advancement in modern construction technology, combining the structural integrity of metal with innovative composite materials to deliver superior performance across diverse architectural applications. These sophisticated building components consist of multiple layers engineered to work synergistically, typically featuring an aluminum or steel outer skin bonded to a lightweight core material such as polyethylene, mineral wool, or honeycomb structures. The composite metal wall panel design maximizes structural efficiency while minimizing weight, creating an optimal solution for both interior and exterior architectural requirements. The primary functions of composite metal wall panels encompass weather protection, thermal insulation, aesthetic enhancement, and structural support for building envelopes. These panels excel in moisture resistance, wind load distribution, and temperature regulation, making them indispensable for commercial, industrial, and residential construction projects. Technologically, composite metal wall panels incorporate advanced bonding techniques that ensure permanent adhesion between layers, preventing delamination and maintaining performance integrity throughout their service life. The manufacturing process utilizes continuous lamination technology, creating seamless bonds that distribute stress evenly across the panel surface. Surface treatments include protective coatings, powder finishes, and specialized textures that enhance durability while providing aesthetic versatility. The applications for composite metal wall panels span numerous industries, including healthcare facilities, educational institutions, retail complexes, manufacturing plants, and high-rise residential buildings. These panels serve as curtain wall systems, rainscreen cladding, interior partitions, and architectural features that demand both functional performance and visual appeal. The composite metal wall panel system adapts to various installation methods, supporting both mechanical fastening and structural glazing techniques. Environmental considerations drive the selection of composite metal wall panels, as they contribute to sustainable building practices through recyclability, energy efficiency, and reduced material waste during construction processes.