aluminium composite panel sheet

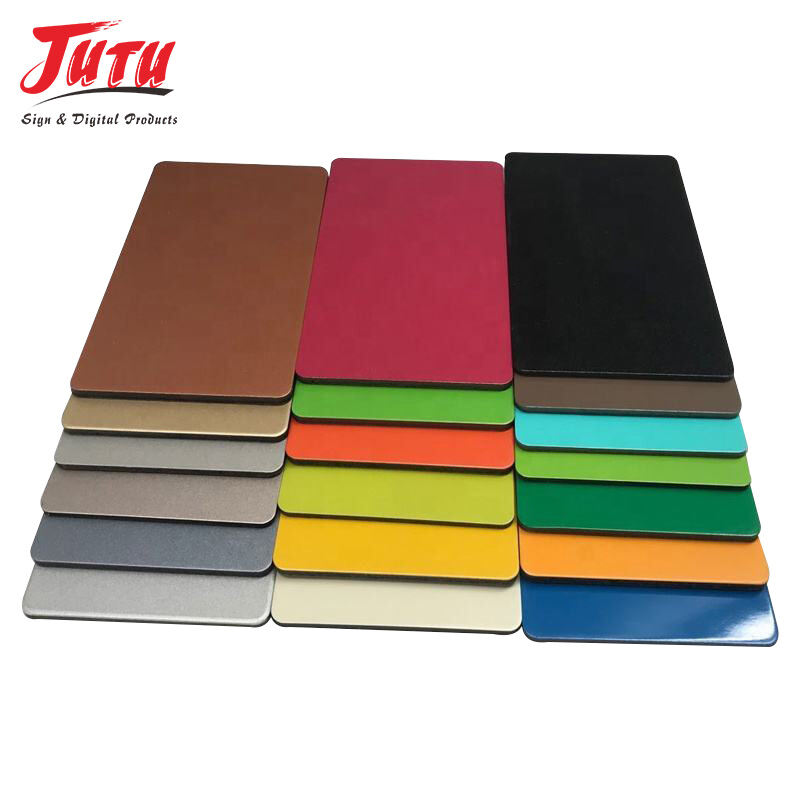

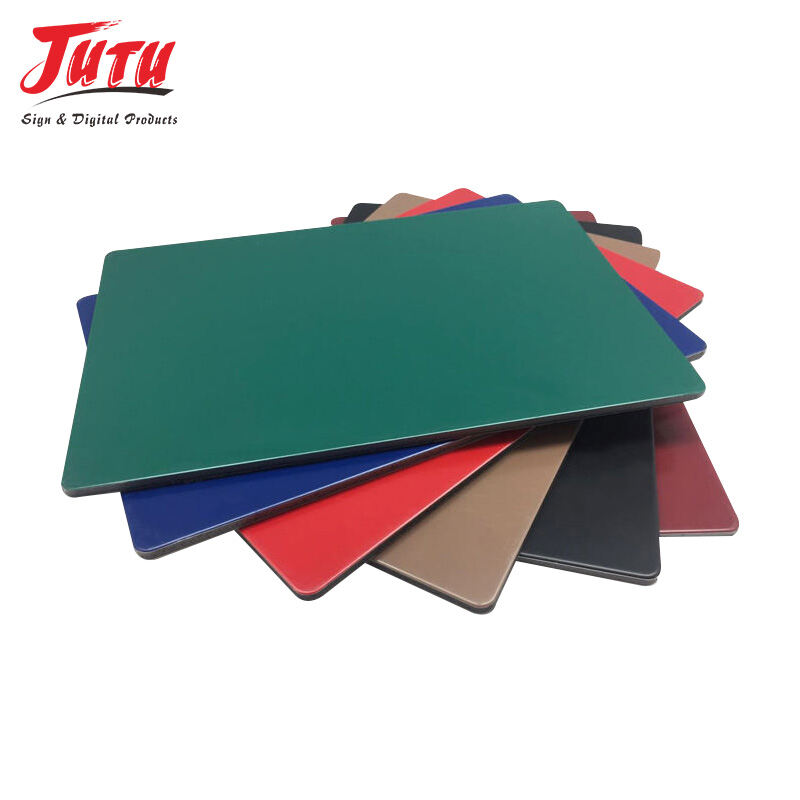

Aluminium composite panel sheet represents a revolutionary building material that has transformed modern architecture and construction. This innovative product consists of two thin aluminium sheets bonded to a thermoplastic core, typically made from polyethylene or mineral-filled materials. The aluminium composite panel sheet offers exceptional structural integrity while maintaining remarkable lightness, making it an ideal choice for both interior and exterior applications. The manufacturing process involves advanced bonding techniques that ensure permanent adhesion between the aluminium faces and the core material, creating a rigid yet flexible panel system. The aluminium composite panel sheet demonstrates superior flatness and dimensional stability compared to traditional building materials. Its surface remains smooth and consistent across large installations, eliminating the waviness often associated with single-skin aluminium sheets. The technological features of aluminium composite panel sheet include excellent thermal expansion characteristics that prevent buckling and warping under temperature variations. The composite structure provides enhanced sound dampening properties, making it suitable for acoustic applications in commercial and residential buildings. Fire-resistant variants of aluminium composite panel sheet incorporate mineral-filled cores that meet stringent building safety standards. The weather resistance of aluminium composite panel sheet ensures long-term performance in harsh environmental conditions, including extreme temperatures, UV exposure, and corrosive atmospheres. Surface treatments such as PVDF coatings provide additional protection against fading and chalking. The aluminium composite panel sheet can be easily fabricated using standard woodworking tools, allowing for precise cutting, drilling, and routing operations. Installation systems for aluminium composite panel sheet include both visible and concealed fixing methods, offering architects flexibility in design execution. The material accepts various finishing techniques including digital printing, allowing for unlimited design possibilities and brand customization opportunities.