cutting aluminum composite panel

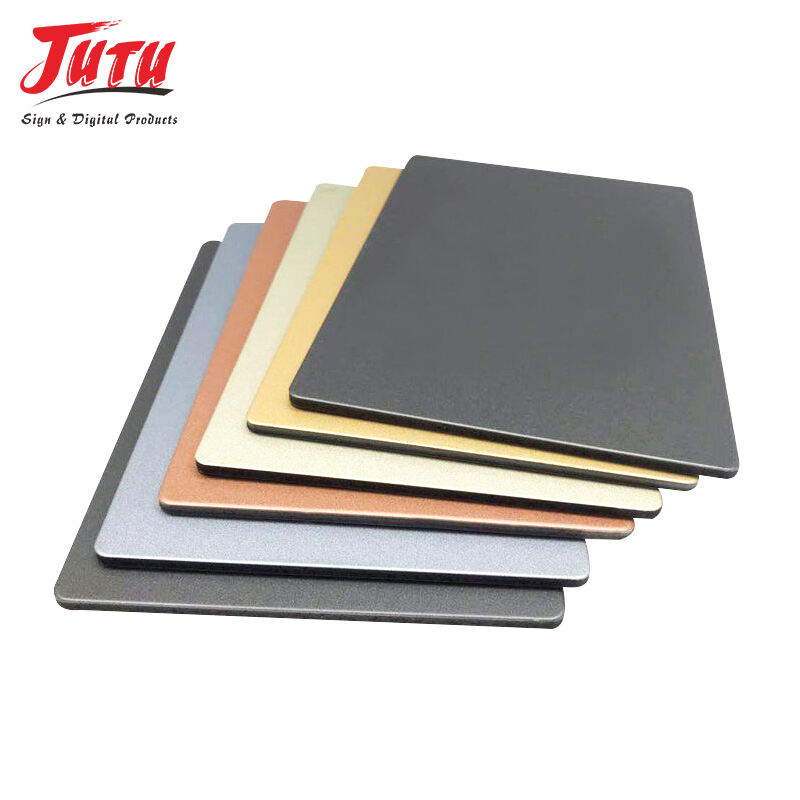

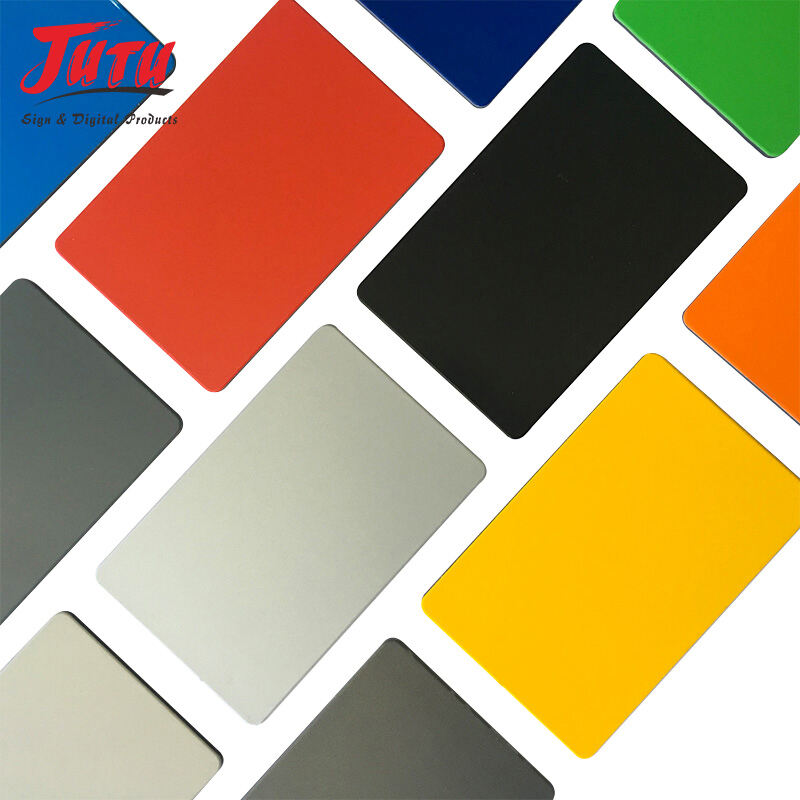

Cutting aluminum composite panel represents a revolutionary approach to modern construction and architectural applications, combining the strength of aluminum with the versatility of composite materials. This innovative building solution consists of two thin aluminum sheets bonded to a non-aluminum core, typically made from polyethylene or mineral-filled materials. The cutting aluminum composite panel technology enables precise fabrication methods that deliver exceptional performance across diverse industries. These panels undergo specialized cutting processes using advanced machinery that ensures clean edges, accurate dimensions, and optimal structural integrity. The main functions of cutting aluminum composite panel include providing lightweight yet durable exterior cladding, interior decorative elements, signage solutions, and industrial applications. The technological features encompass superior weather resistance, excellent thermal insulation properties, and outstanding fire safety characteristics when manufactured with mineral cores. Modern cutting aluminum composite panel systems incorporate state-of-the-art manufacturing processes that guarantee consistent quality and dimensional accuracy. The panels demonstrate exceptional flatness, making them ideal for applications requiring smooth surfaces and professional aesthetics. Applications span across commercial buildings, residential projects, transportation infrastructure, and retail environments. The cutting aluminum composite panel technology supports various finishing options including anodized, painted, and textured surfaces that meet specific design requirements. Installation procedures for cutting aluminum composite panel systems have been streamlined through innovative mounting systems and standardized connection methods. Quality control measures ensure each cutting aluminum composite panel meets stringent industry standards for durability, safety, and performance. The versatility of cutting aluminum composite panel materials allows architects and designers to create stunning facades while maintaining cost-effectiveness and structural reliability throughout the building lifecycle.