pvc foam sheet bunnings

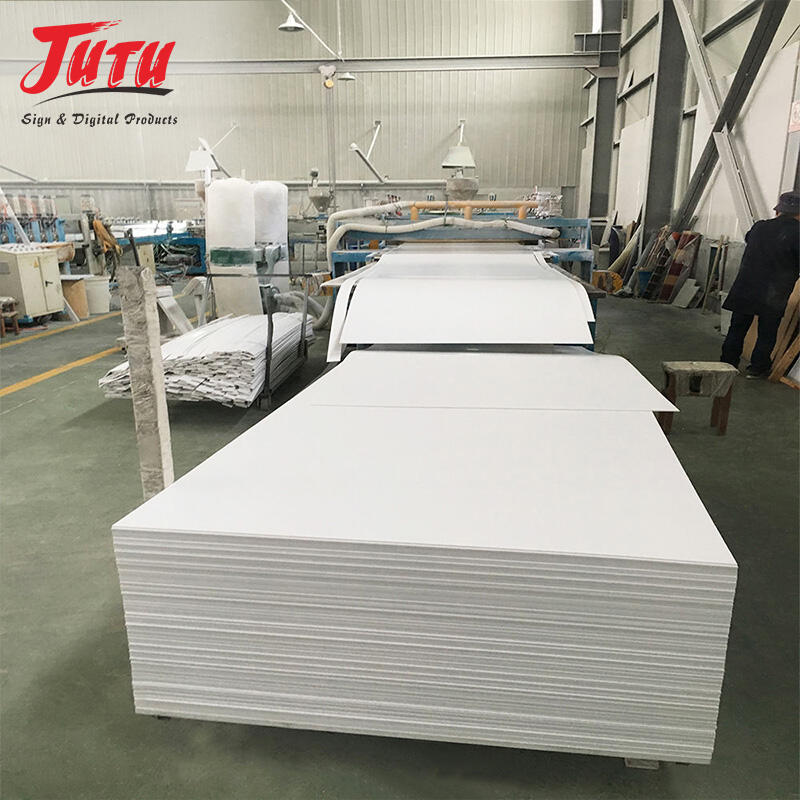

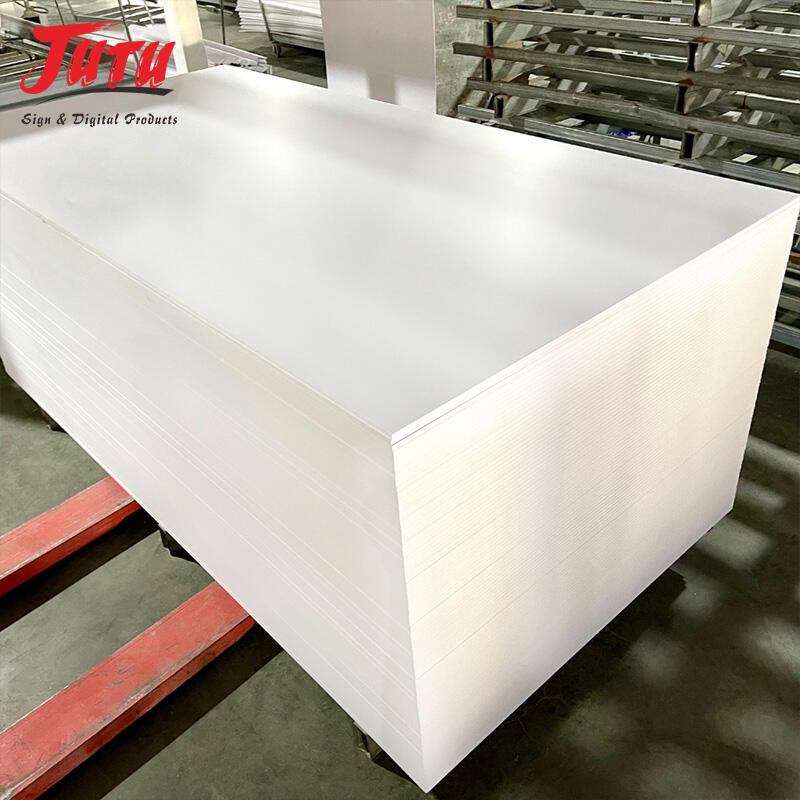

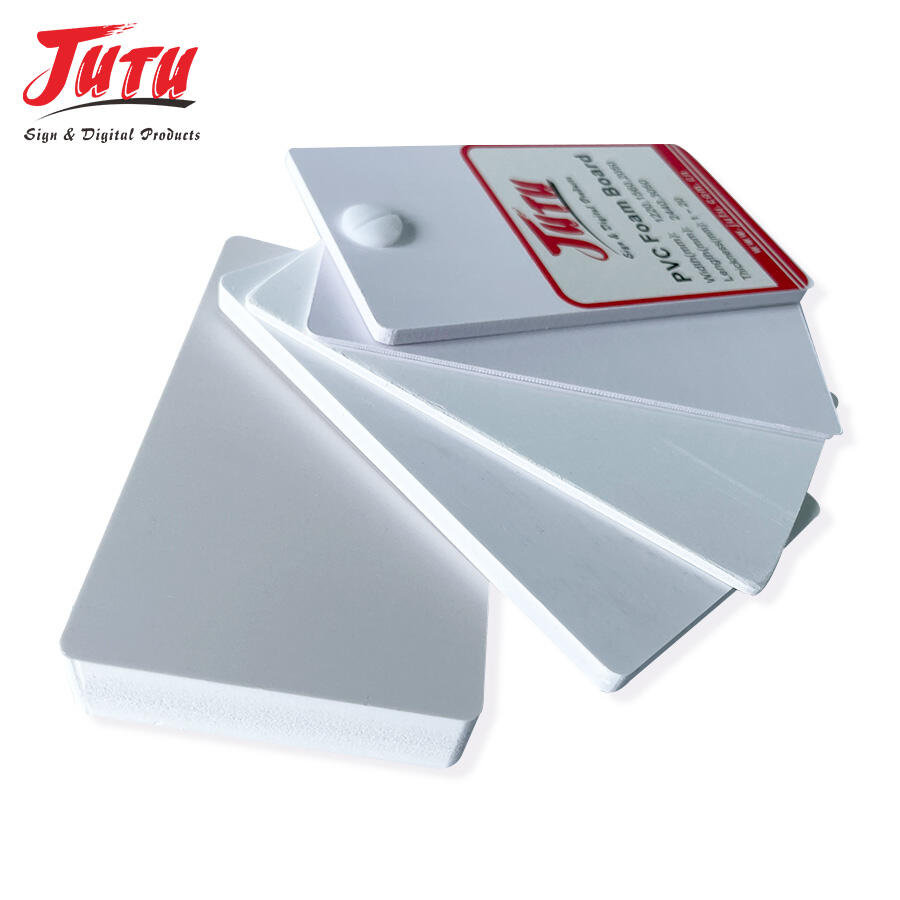

PVC foam sheet bunnings represents a revolutionary building material that has transformed modern construction and DIY projects across residential and commercial applications. These innovative sheets combine the durability of traditional PVC with advanced foam core technology, creating a lightweight yet robust material perfect for various construction needs. The pvc foam sheet bunnings available through major retailers offers exceptional versatility, making it an ideal choice for both professional contractors and weekend warriors tackling home improvement projects. The material features a closed-cell foam structure that provides superior insulation properties while maintaining structural integrity under diverse environmental conditions. Key technological features include excellent chemical resistance, UV stability, and moisture impermeability that ensures long-lasting performance in challenging environments. The manufacturing process involves extruding PVC resin with specialized foaming agents, creating a uniform cellular structure throughout the sheet thickness. This results in a material that weighs significantly less than solid PVC alternatives while retaining comparable strength characteristics. Primary applications encompass architectural cladding, signage substrates, furniture components, marine applications, and industrial fabrication projects. The pvc foam sheet bunnings comes in various thicknesses ranging from 1mm to 30mm, accommodating different structural requirements and design specifications. Surface finishes include smooth, textured, and embossed options that cater to aesthetic preferences and functional needs. The material exhibits excellent machinability, allowing for easy cutting, drilling, routing, and thermoforming using standard woodworking tools. Temperature resistance spans from -20°C to 70°C, ensuring reliable performance across seasonal variations. Fire retardant variants meet building code requirements for commercial installations, while standard grades serve residential applications effectively. The dimensional stability of pvc foam sheet bunnings prevents warping, shrinking, or expanding under normal use conditions, maintaining precise tolerances throughout the product lifecycle. Color options include white, black, and custom tinted variations that eliminate the need for additional finishing processes in many applications.