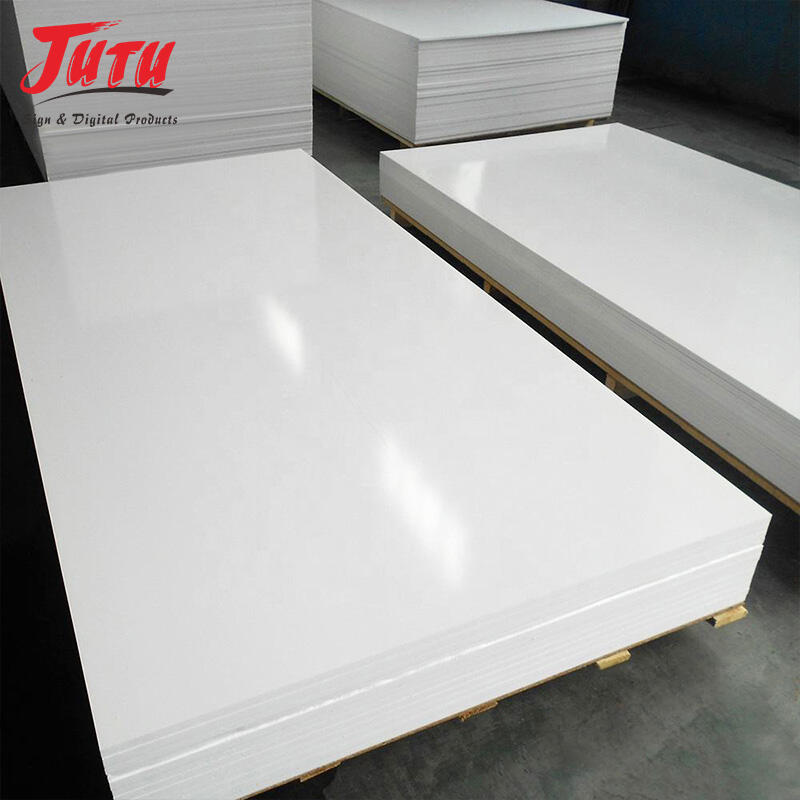

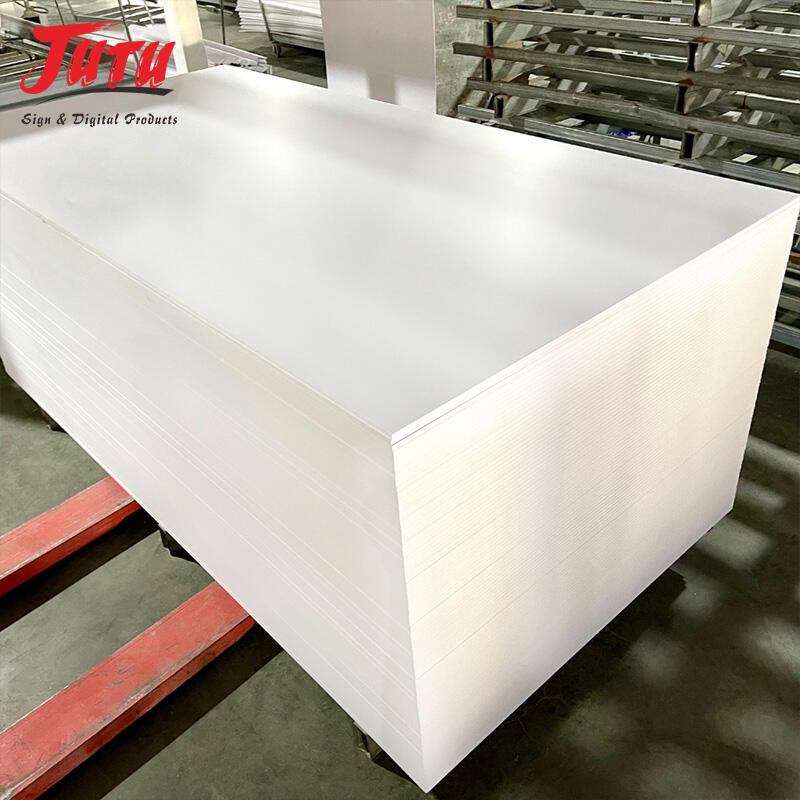

Versatile Applications and Easy Installation Process

The remarkable adaptability of sunboard foam board enables successful implementation across diverse industries and applications, from architectural panels and signage to marine components and specialized industrial uses. Manufacturing flexibility allows sunboard foam board to be produced in various thicknesses, densities, and surface treatments that match specific project requirements without costly customization processes. The workability of sunboard foam board with standard tools empowers contractors and DIY enthusiasts to achieve professional results using familiar equipment, eliminating the need for specialized training or expensive machinery. Cutting operations on sunboard foam board produce clean, precise edges using conventional saws, knives, and routing equipment, enabling accurate fitting and professional-looking joints that enhance overall project quality. Fastening options for sunboard foam board include mechanical fasteners, adhesives, and specialized attachment systems that accommodate various structural requirements and aesthetic preferences. The uniform composition of sunboard foam board ensures consistent performance during installation, eliminating surprises and rework that can derail project schedules and budgets. Surface preparation requirements for sunboard foam board are minimal compared to traditional materials, reducing installation time and labor costs while achieving superior finish quality. The dimensional accuracy of sunboard foam board supports precision installations where tight tolerances are critical, such as architectural cladding and decorative elements that require perfect alignment. Weather resistance properties allow sunboard foam board installation to continue under conditions that would halt work with moisture-sensitive materials, improving project scheduling flexibility. The forgiving nature of sunboard foam board accommodates minor installation errors that can be corrected easily, reducing waste and material costs associated with mistakes. Quality assurance during sunboard foam board installation is straightforward because visual inspection can identify proper placement and adhesion, eliminating complex testing requirements that slow project progress.