3d pvc foam wall panels

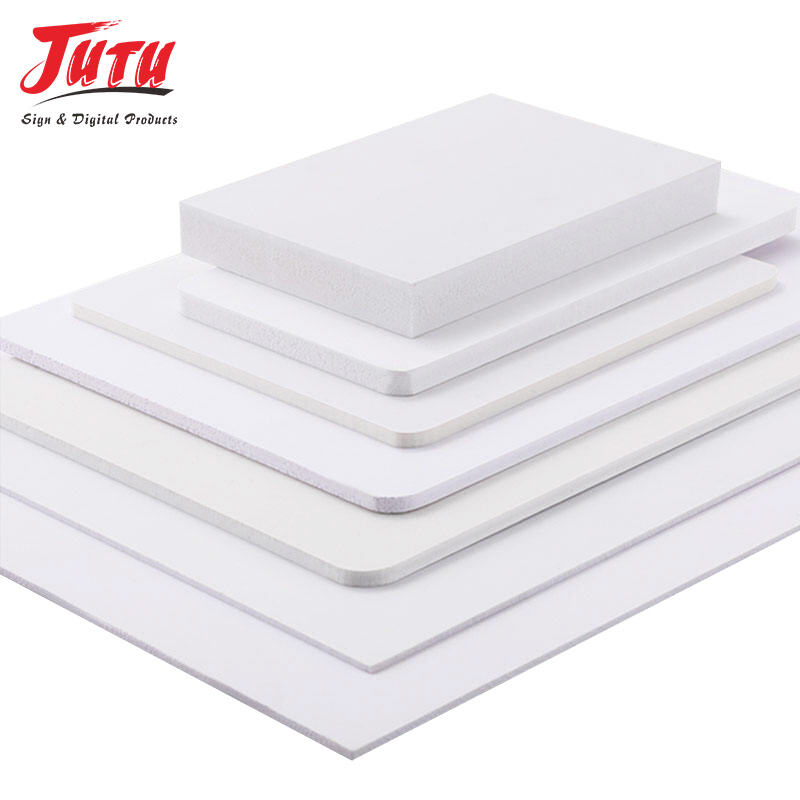

3D PVC foam wall panels represent a revolutionary advancement in modern interior design and construction materials, offering an innovative solution for both residential and commercial spaces. These lightweight yet durable panels combine the versatility of PVC with advanced foam core technology to create visually striking three-dimensional surface textures that transform ordinary walls into architectural masterpieces. The unique manufacturing process involves injecting high-quality PVC material with specialized foaming agents, creating a cellular structure that delivers exceptional performance characteristics while maintaining cost-effectiveness. The panels feature intricate geometric patterns, organic designs, and contemporary motifs that add depth and visual interest to any interior environment. Technologically, 3D PVC foam wall panels incorporate closed-cell foam construction that provides superior insulation properties, moisture resistance, and dimensional stability. The manufacturing process ensures consistent thickness, precise edge profiles, and uniform surface textures that facilitate seamless installation. These panels are engineered with interlocking systems or adhesive-ready surfaces that simplify mounting procedures for both professional contractors and DIY enthusiasts. The material composition includes UV-stabilized additives that prevent color fading and surface degradation, ensuring long-lasting aesthetic appeal. Applications for 3D PVC foam wall panels span across multiple sectors including hospitality, retail, healthcare, residential, and office environments. They excel in accent wall installations, reception areas, restaurants, bedrooms, living rooms, and commercial spaces where visual impact is paramount. The panels effectively conceal imperfections in existing wall surfaces while adding architectural interest without the expense of traditional sculptural elements. Their lightweight nature makes them suitable for renovation projects where structural load considerations are important, and their water-resistant properties make them ideal for bathrooms, kitchens, and high-humidity environments where traditional wall coverings might fail.