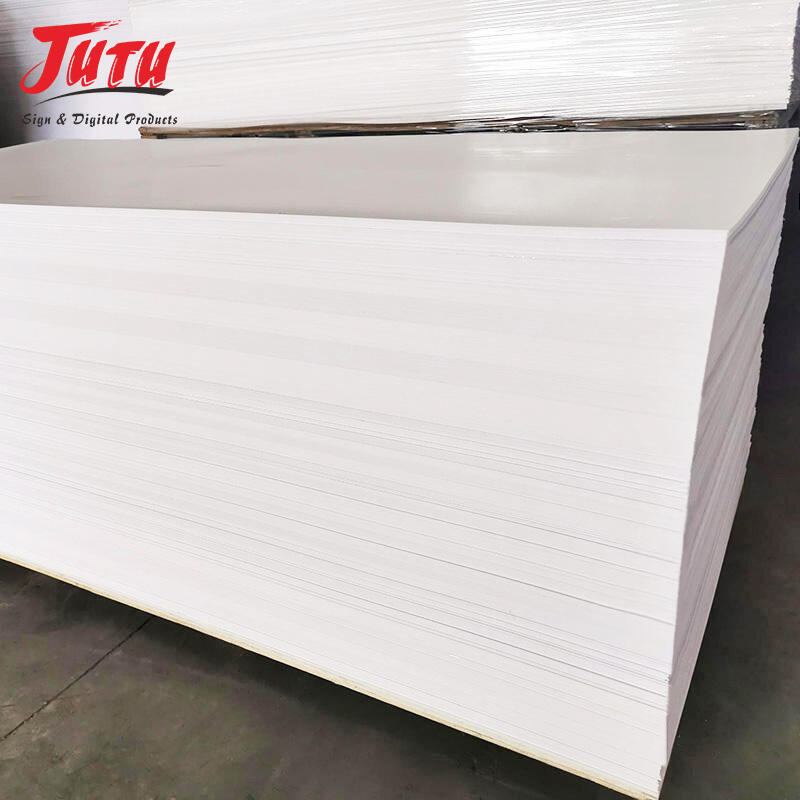

Exceptional Durability and Weather Resistance for Long-Term Performance

PVC foam waterproof demonstrates remarkable longevity through its engineered resistance to environmental factors that typically degrade conventional waterproofing materials, delivering decades of reliable protection with minimal maintenance requirements. The material's exceptional durability stems from advanced polymer stabilization techniques that protect against UV radiation degradation, preventing the brittleness and cracking that commonly affect exposed waterproofing systems. Specialized UV stabilizers integrated throughout the material's matrix absorb harmful radiation and dissipate energy harmlessly, maintaining flexibility and waterproof integrity even under intense solar exposure. Weather resistance capabilities extend beyond UV protection to include remarkable performance in extreme temperature conditions, with thermal cycling tests demonstrating consistent properties through thousands of freeze-thaw cycles without structural deterioration. The material maintains flexibility at temperatures as low as -40°C while retaining dimensional stability at elevated temperatures up to 80°C, accommodating the full range of climatic conditions encountered in global construction applications. Chemical resistance properties protect against degradation from acid rain, industrial pollutants, and common building chemicals, ensuring consistent performance in urban and industrial environments where conventional materials may fail prematurely. Advanced formulations incorporate antioxidants that prevent polymer chain breakdown caused by oxidative stress, maintaining mechanical properties throughout extended service periods. Accelerated aging tests simulate decades of environmental exposure in laboratory conditions, demonstrating that pvc foam waterproof retains over 90% of its original properties after equivalent exposure periods that would significantly degrade alternative materials. The material's resistance to biological attack prevents degradation from algae, bacteria, and fungi that can compromise organic waterproofing systems, particularly important in humid climates or applications with limited ventilation. Mechanical durability includes exceptional tear resistance and puncture protection, preventing damage during installation and throughout the building's operational life. Wind uplift resistance exceeds industry standards for roofing applications, providing reliable performance in hurricane-prone regions where waterproofing system failure can result in catastrophic property damage. The combination of chemical, thermal, and mechanical stability ensures predictable long-term performance that building owners can rely upon for comprehensive moisture protection throughout the structure's design life.