Versatile Customization Capabilities

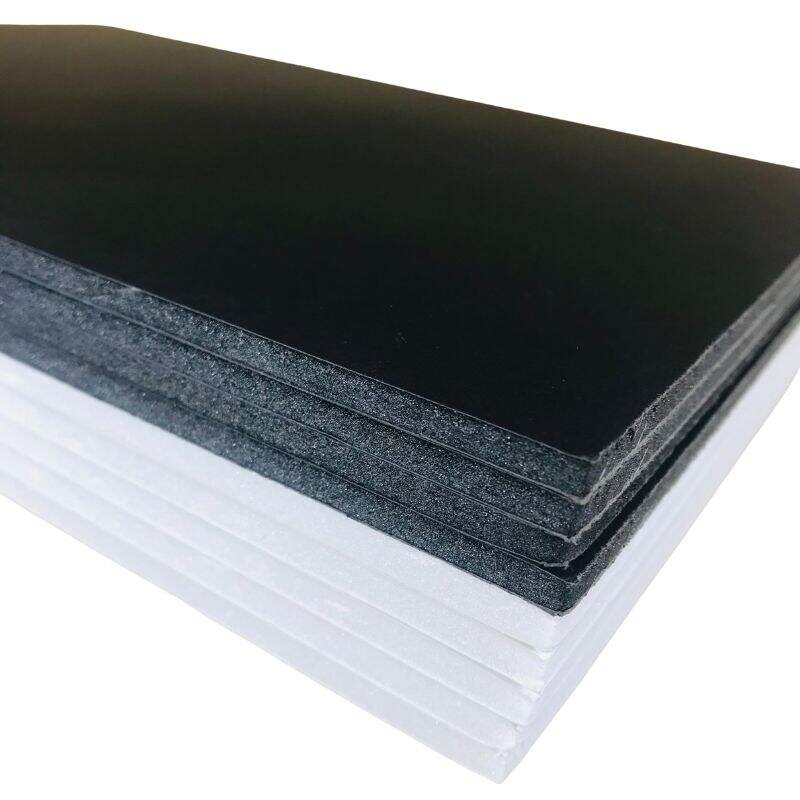

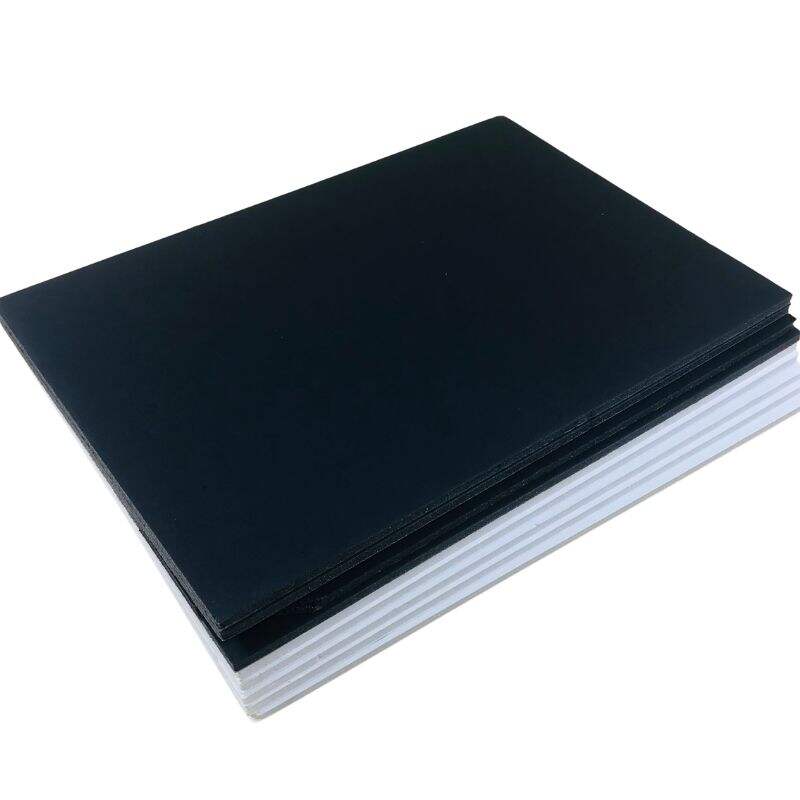

Paper foam board for packaging offers unparalleled design flexibility that enables businesses to create precisely tailored packaging solutions for virtually any product configuration or protection requirement. The material properties of paper foam board for packaging allow for intricate cutting patterns, complex folding sequences, and three-dimensional shaping that accommodates irregular product geometries while maintaining structural integrity. Custom thickness options ranging from ultra-thin protective layers to heavy-duty cushioning systems ensure that paper foam board for packaging can address diverse protection needs across industries from delicate electronics to robust industrial components. Computer-aided design integration supports rapid prototyping of paper foam board for packaging solutions, allowing packaging engineers to visualize and test custom configurations before committing to full-scale production runs. Die-cutting capabilities enable mass production of standardized paper foam board for packaging inserts while maintaining precise dimensional tolerances that ensure consistent fit and protection across large product volumes. The surface characteristics of paper foam board for packaging accept various printing techniques, enabling brand customization, product identification, and assembly instructions to be incorporated directly into the protective packaging material. Lamination compatibility allows paper foam board for packaging to be combined with other materials such as moisture barriers, anti-static films, or decorative surfaces to meet specific application requirements. Compression molding techniques can shape paper foam board for packaging into complex three-dimensional forms that cradle products with precision fit while eliminating the need for multiple packaging components. The workability of paper foam board for packaging extends to field modifications, allowing end-users to trim, fold, or reshape the material using common tools to accommodate last-minute product changes or size variations. Color customization options provide branding opportunities through paper foam board for packaging while maintaining material performance characteristics, supporting marketing objectives and product differentiation strategies. Adhesive compatibility ensures that paper foam board for packaging bonds effectively with various closure systems, tapes, and assembly methods commonly used in packaging operations. Multi-layer construction possibilities enable paper foam board for packaging to incorporate different density zones within a single piece, providing graduated protection levels that optimize material usage while maximizing protection effectiveness. This extensive customization capability makes paper foam board for packaging the ideal solution for businesses requiring packaging flexibility without sacrificing protection quality or environmental responsibility.