Comprehensive Product Customization and Application Versatility

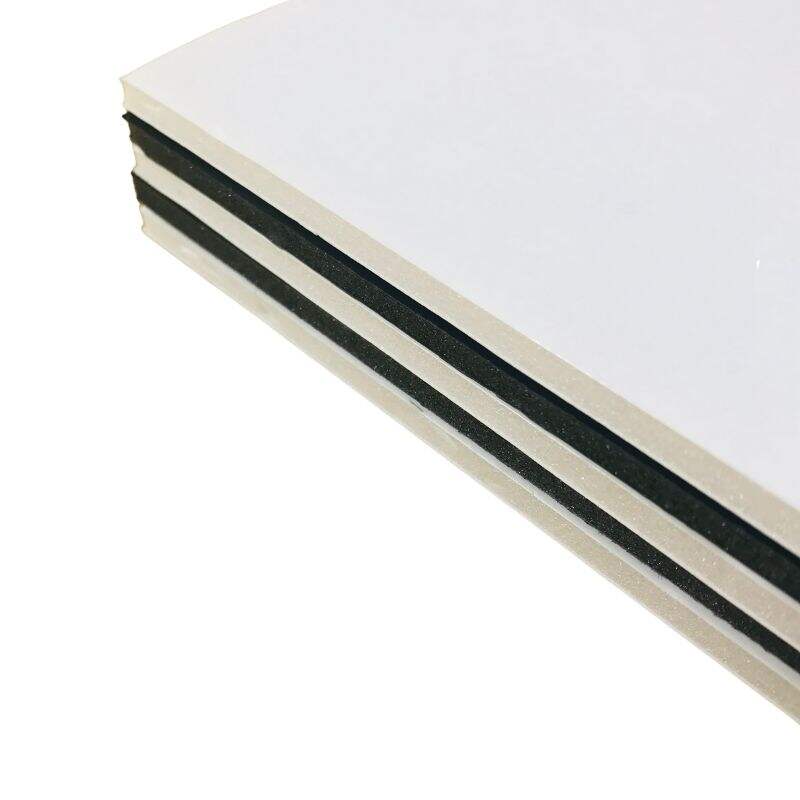

The ability to provide extensive customization options represents a crucial competitive advantage offered by established paper backed foam board manufacturer companies, enabling customers to obtain precisely tailored solutions for their specific project requirements. Professional manufacturers maintain flexible production capabilities that accommodate variations in foam density, board thickness, paper surface textures, and specialized treatments to meet diverse application needs across construction, signage, display, and industrial sectors. This customization expertise extends to developing specialized products for unique applications, such as fire-resistant formulations for commercial buildings, moisture-resistant versions for bathroom installations, or high-strength variants for structural support applications. Leading paper backed foam board manufacturer facilities typically offer multiple foam core options, including expanded polystyrene, extruded polystyrene, polyurethane, and polyisocyanurate materials, each providing distinct performance characteristics suited to different environmental conditions and performance requirements. The paper backing customization capabilities include various paper weights, surface textures, colors, and coating treatments that enhance specific properties such as paint adhesion, moisture resistance, or decorative appearance. Custom sizing services provided by experienced manufacturers eliminate material waste and reduce installation labor, as customers receive products cut to exact dimensions for their projects rather than having to modify standard-sized boards on-site. Specialized edge treatments and profile cutting services enable manufacturers to provide products ready for immediate installation, including tongue-and-groove joints, beveled edges, or complex geometric shapes that would be difficult to achieve with field modifications. The versatility of paper backed foam board products manufactured by professional companies extends across architectural applications, including wall insulation, ceiling panels, signage substrates, display boards, theatrical sets, architectural models, and specialty packaging solutions. Technical consultation services help customers identify optimal product configurations for their specific applications, considering factors such as environmental exposure, load requirements, thermal performance goals, and aesthetic considerations. This comprehensive customization capability allows a single paper backed foam board manufacturer to serve multiple market segments effectively, providing specialized solutions that meet the unique demands of each industry while maintaining economies of scale in production operations.