paper foam sheet manufacturer

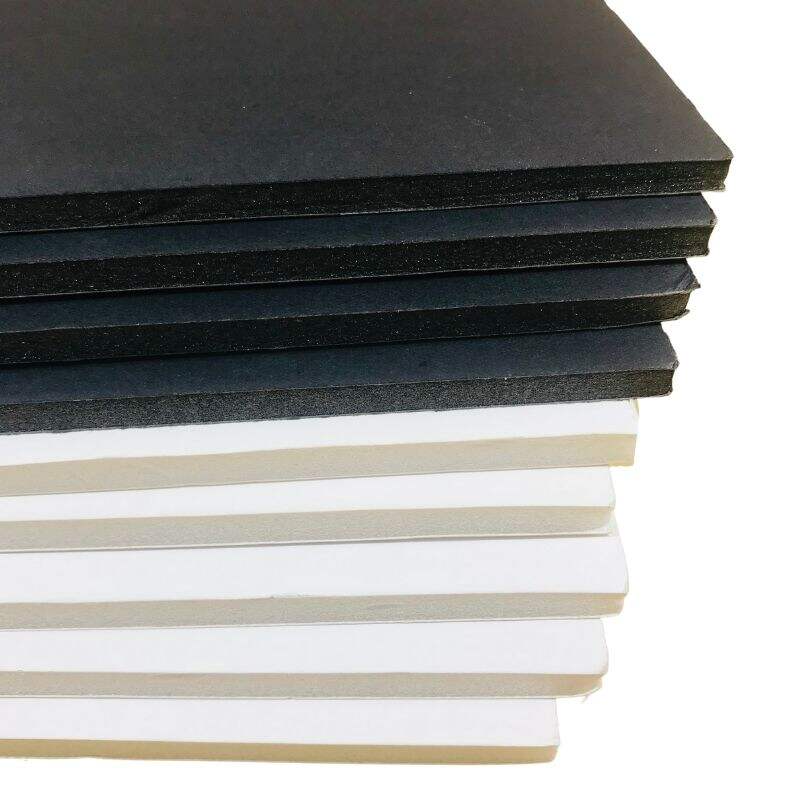

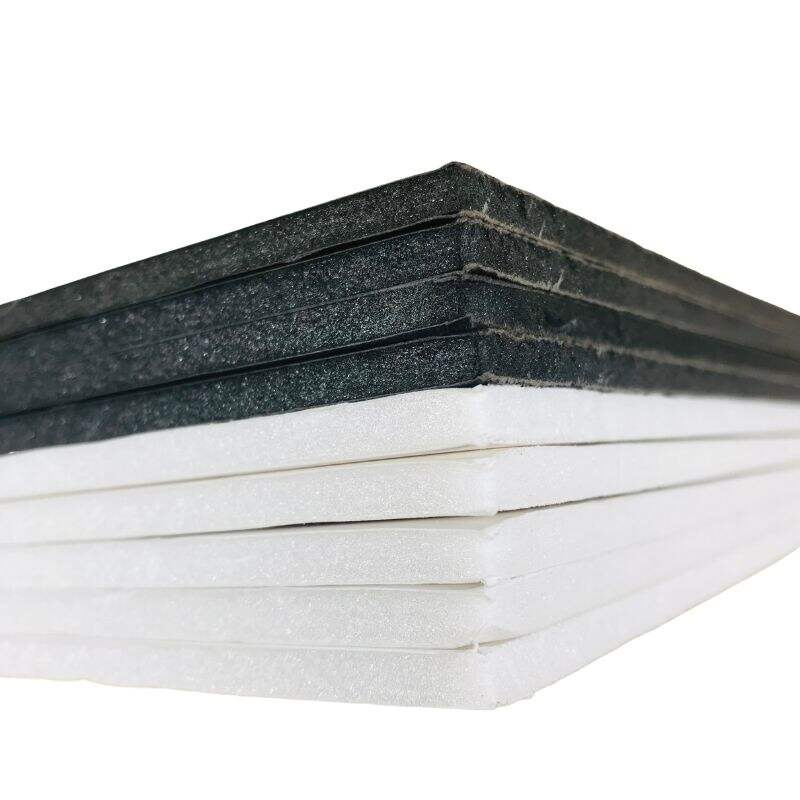

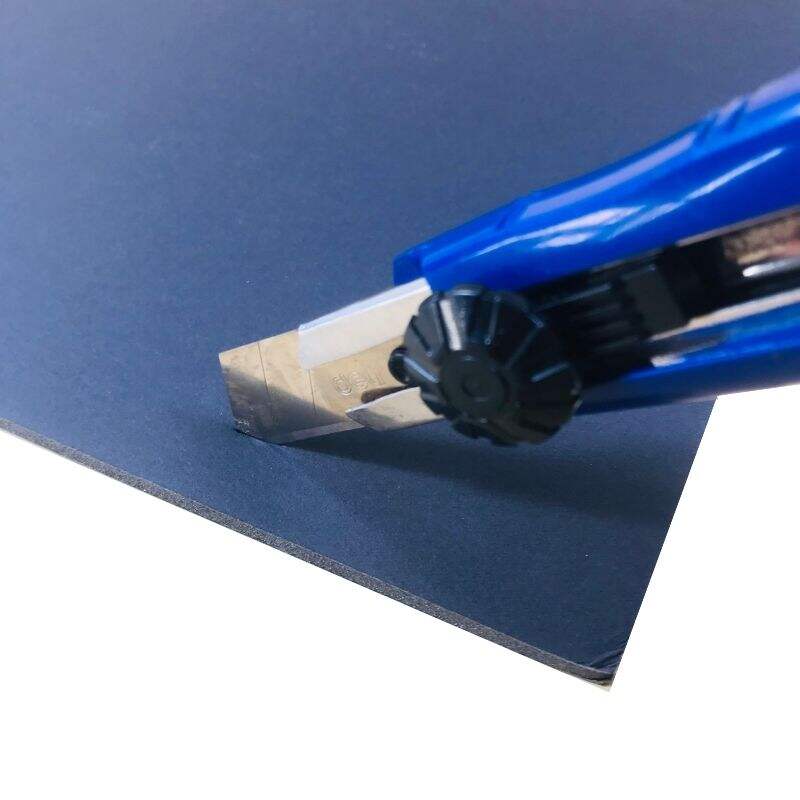

A paper foam sheet manufacturer represents a specialized industrial enterprise that produces innovative lightweight materials through advanced manufacturing processes. These manufacturers combine traditional paper-making techniques with modern foam technology to create unique composite materials that serve multiple industries. The primary function of a paper foam sheet manufacturer involves transforming raw materials including recycled paper fibers, natural polymers, and eco-friendly additives into structured foam sheets with exceptional properties. The manufacturing process utilizes sophisticated machinery that controls temperature, pressure, and chemical composition to achieve consistent product quality. Modern paper foam sheet manufacturers employ cutting-edge technology including automated mixing systems, precision forming equipment, and computerized quality control mechanisms. These technological features enable manufacturers to produce sheets with varying densities, thicknesses, and performance characteristics tailored to specific customer requirements. The production facilities typically incorporate environmental monitoring systems that ensure minimal waste generation and optimal energy efficiency throughout the manufacturing cycle. Applications for paper foam sheets span numerous sectors including packaging, construction, automotive, electronics, and consumer goods industries. In packaging applications, these sheets provide excellent cushioning properties while maintaining biodegradability, making them ideal alternatives to traditional petroleum-based foam materials. Construction industry applications include thermal insulation panels, lightweight building components, and sound dampening materials. The automotive sector utilizes paper foam sheets for interior components, noise reduction panels, and impact-absorbing elements. Electronics manufacturers rely on these materials for protective packaging of sensitive components and static-free storage solutions. The versatility of paper foam sheet manufacturers allows them to customize products based on specific density requirements, surface treatments, and dimensional specifications, ensuring optimal performance across diverse applications while maintaining environmental sustainability standards.