mirror aluminum composite panel

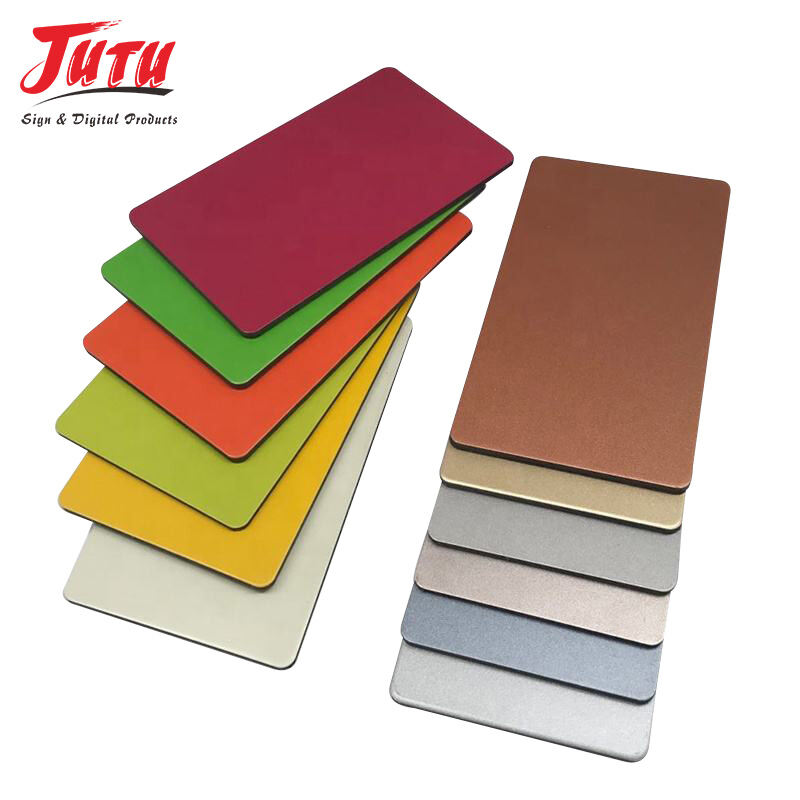

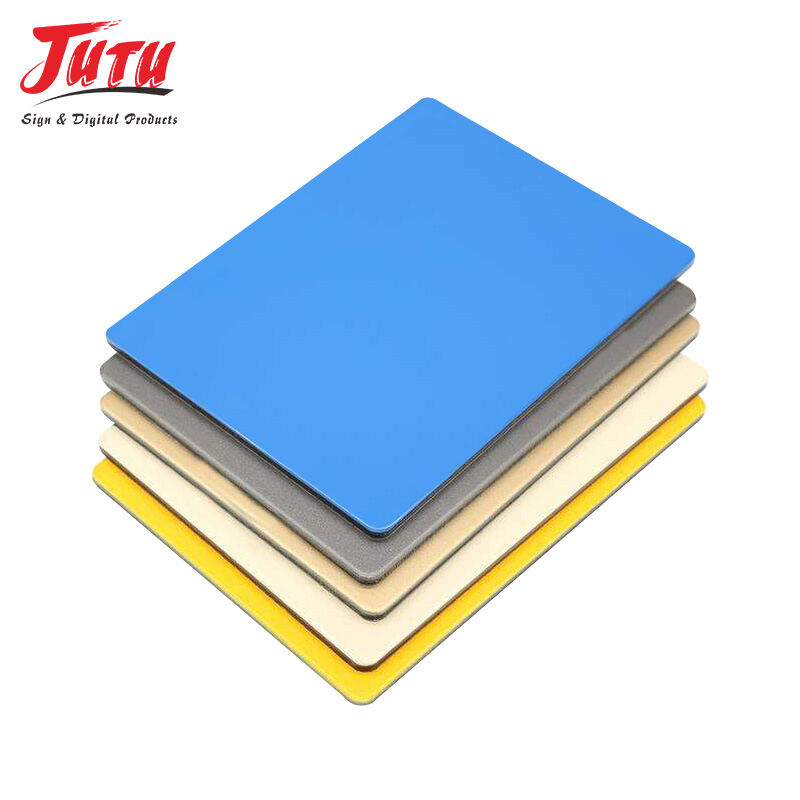

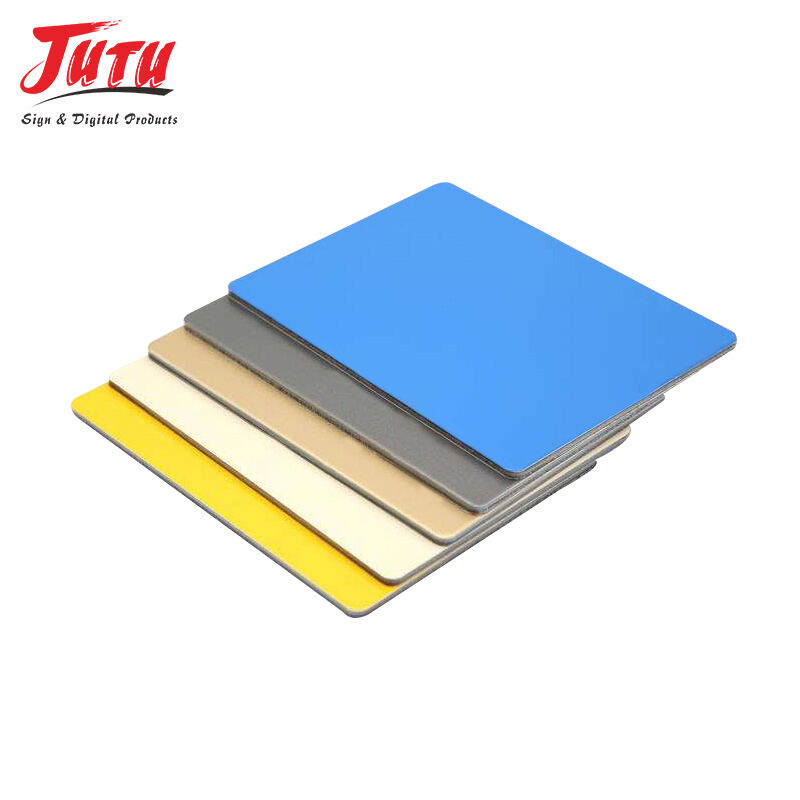

Mirror aluminum composite panel represents an innovative architectural material that combines the durability of aluminum with the aesthetic appeal of a reflective surface. This advanced building material consists of two thin aluminum sheets bonded to a non-aluminum core, typically made of polyethylene or mineral-filled material, creating a lightweight yet robust construction solution. The mirror finish is achieved through specialized coating processes that provide exceptional reflectivity while maintaining the structural integrity of the underlying composite panel. These panels offer architects and designers unprecedented flexibility in creating visually striking facades that interact dynamically with their surroundings. The technological foundation of mirror aluminum composite panel relies on advanced adhesive systems that ensure permanent bonding between layers, preventing delamination even under extreme weather conditions. The manufacturing process involves precision rolling, coating, and lamination techniques that result in perfectly flat surfaces with consistent reflective properties across the entire panel surface. Key functions of mirror aluminum composite panel include weather protection, thermal insulation, and aesthetic enhancement of building exteriors. The reflective surface effectively redirects solar radiation, contributing to energy efficiency by reducing heat absorption. Additionally, these panels serve as effective moisture barriers while allowing for thermal expansion and contraction without compromising structural integrity. Applications for mirror aluminum composite panel span across commercial, residential, and industrial sectors. High-rise office buildings frequently utilize these panels for curtain wall systems, creating impressive mirror facades that reflect the sky and surrounding architecture. Shopping centers, hotels, and entertainment venues benefit from the eye-catching appearance that mirror aluminum composite panel provides. The material also finds applications in interior design, where it creates spacious illusions and adds contemporary sophistication to lobbies, exhibition spaces, and retail environments.