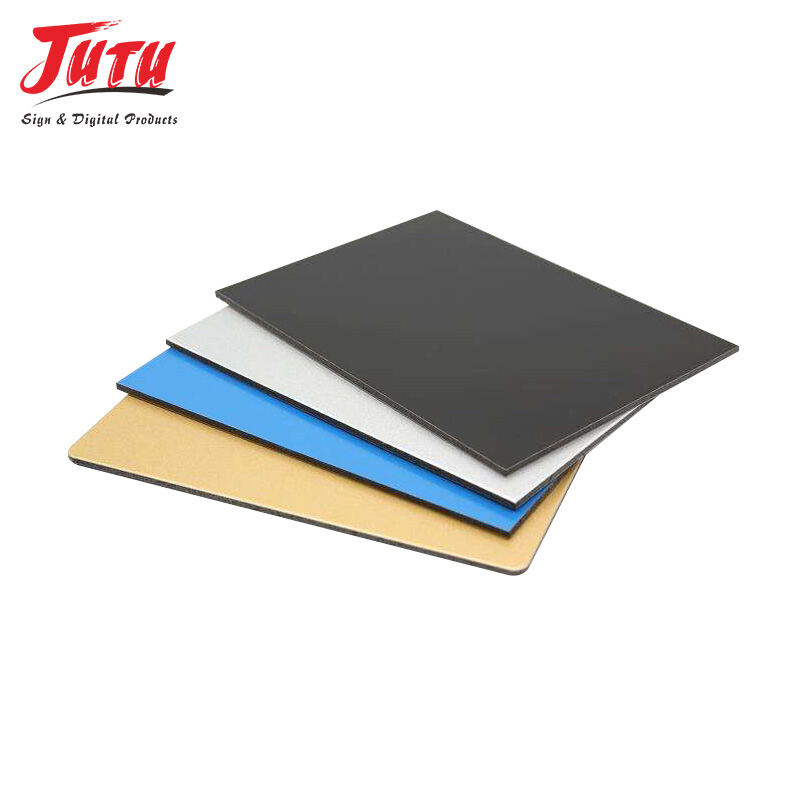

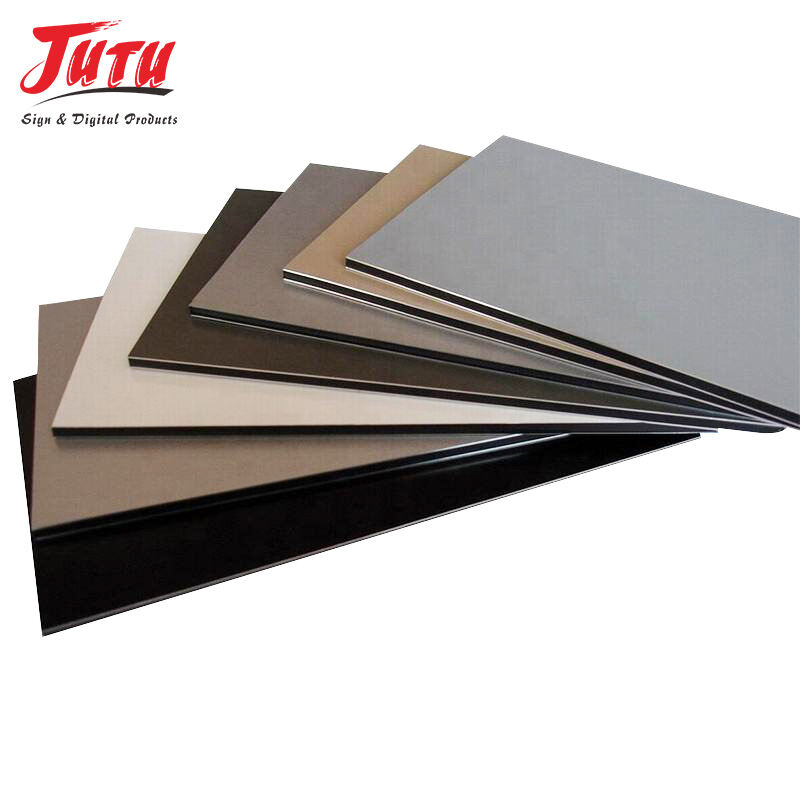

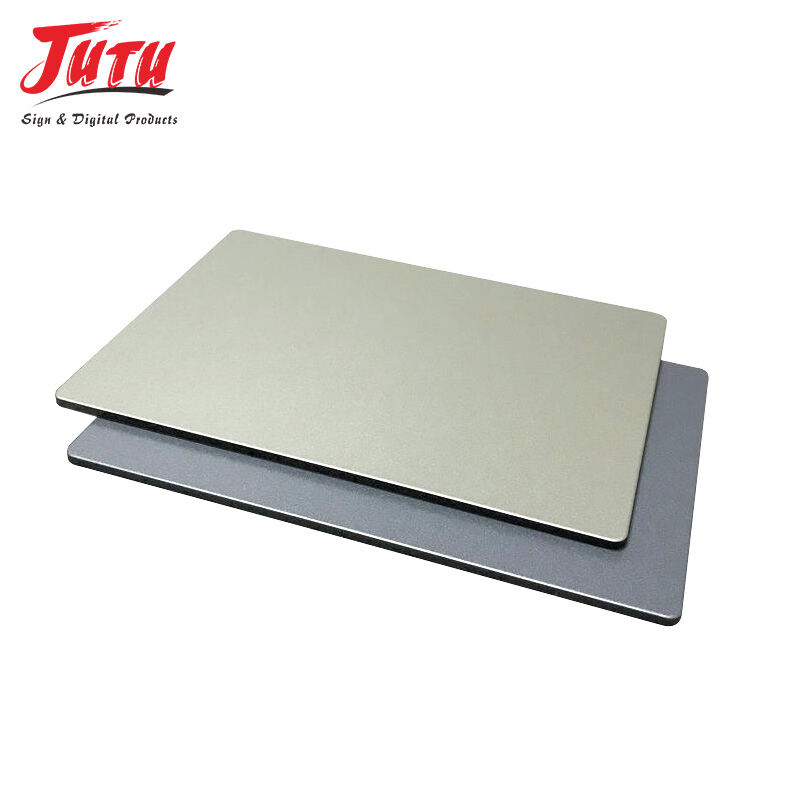

aluminium acp sheet

Aluminium ACP sheet, also known as Aluminum Composite Panel, represents a revolutionary building material that has transformed modern construction and architectural design. This innovative product consists of two thin aluminum sheets bonded to a non-aluminum core, typically made of polyethylene or mineral-filled materials. The aluminium acp sheet delivers exceptional performance through its unique three-layer sandwich structure, combining the strength and durability of aluminum with lightweight properties and enhanced insulation capabilities. The manufacturing process involves advanced bonding technology that ensures permanent adhesion between layers, creating a uniform and stable composite material. Aluminium acp sheet technology incorporates sophisticated coating systems that provide superior weather resistance, UV protection, and color retention over extended periods. The panels feature precision-engineered surfaces that can accommodate various finishes, including brushed, mirror, wood grain, stone texture, and solid colors. These sheets maintain dimensional stability across temperature variations while offering excellent flatness and consistent thickness throughout their surface area. The core material in aluminium acp sheet construction provides thermal and acoustic insulation properties, making these panels ideal for both interior and exterior applications. Modern aluminium acp sheet products undergo rigorous quality control processes to ensure compliance with international building standards and fire safety regulations. The versatility of aluminium acp sheet extends to its fabrication capabilities, allowing for easy cutting, bending, drilling, and routing to create complex architectural forms and designs. Installation systems for aluminium acp sheet include various mounting methods such as wet glazing, structural glazing, and mechanical fixing systems, providing flexibility for different project requirements and environmental conditions.