Exceptional Design Flexibility and Aesthetics

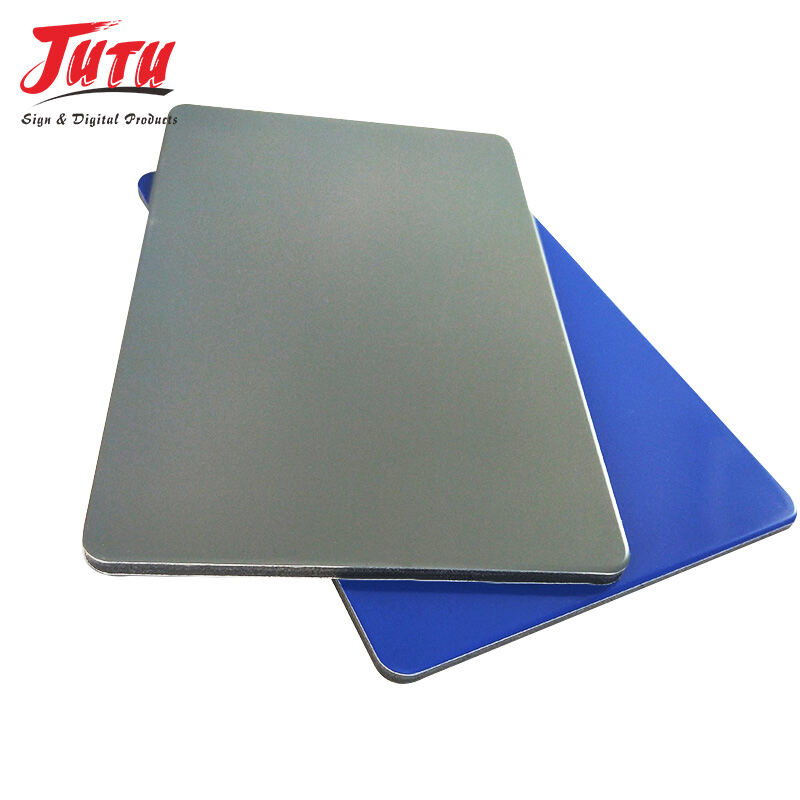

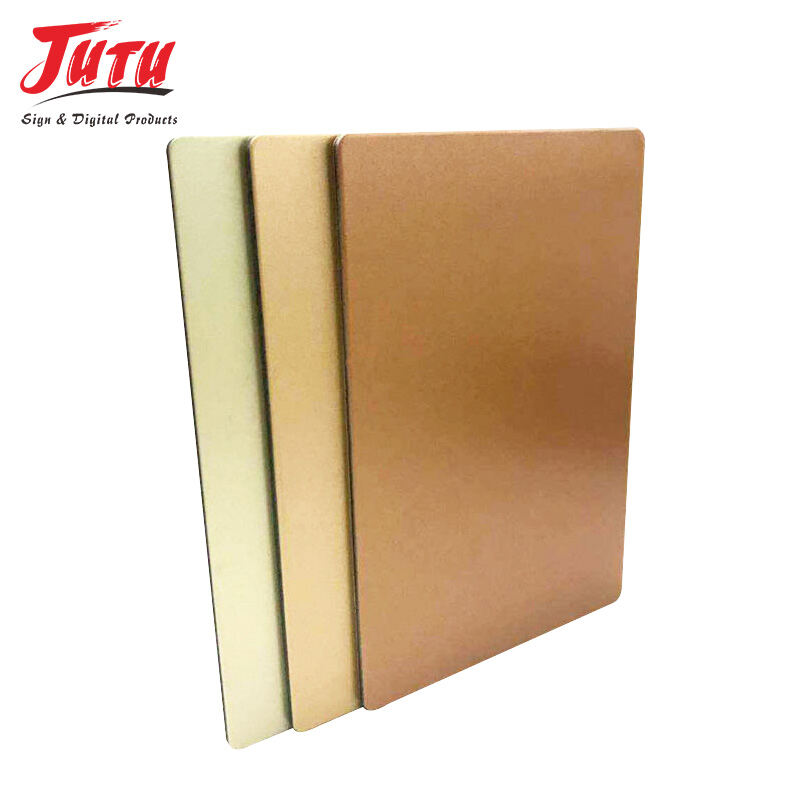

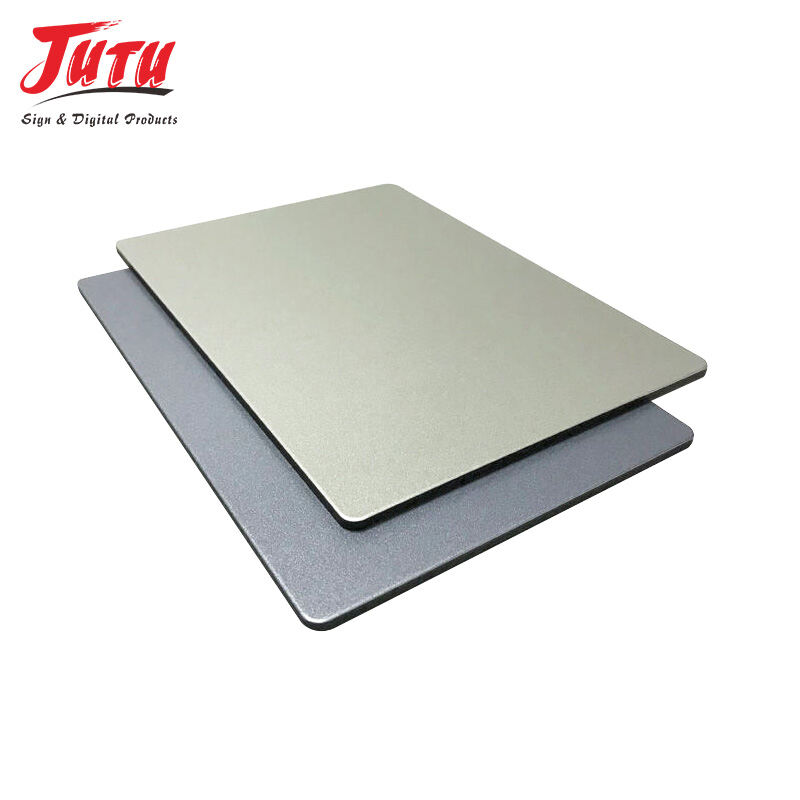

The exterior aluminum composite panel delivers unmatched design flexibility that empowers architects to realize their creative visions while meeting practical construction requirements. This remarkable material can be fabricated into virtually any shape, from simple flat panels to complex curved surfaces that follow architectural curves and angles. The exterior aluminum composite panel accepts various forming techniques, including bending, folding, and routing, allowing designers to create three-dimensional facade elements that add depth and visual interest to building exteriors. Advanced digital printing technology enables exterior aluminum composite panel surfaces to replicate natural materials like wood, stone, and metal with stunning accuracy, providing the aesthetic appeal of expensive materials at a fraction of the cost. The color palette available for exterior aluminum composite panel applications includes thousands of standard options plus unlimited custom colors that can match specific design requirements or corporate branding needs. Texture variations range from smooth, mirror-like finishes to brushed, embossed, and perforated patterns that create dynamic light and shadow effects throughout the day. The exterior aluminum composite panel can incorporate integrated lighting systems, creating dramatic nighttime facades that transform building appearance after dark. Modular design capabilities allow exterior aluminum composite panel systems to accommodate building expansion or renovation projects seamlessly, maintaining aesthetic continuity while adapting to changing functional requirements. The material's dimensional stability ensures that complex geometric patterns and precise alignment remain consistent over time, preventing the warping or distortion that can compromise architectural intent. Installation versatility means exterior aluminum composite panel systems can be applied to new construction or retrofit existing buildings, making them suitable for renovation projects where weight limitations restrict material choices. The panels can incorporate functional elements like ventilation grilles, signage mounting points, and maintenance access panels without compromising the overall design aesthetic. Quality exterior aluminum composite panel manufacturers offer comprehensive design support services, including computer modeling and prototype fabrication, helping architects optimize their designs for both performance and visual impact.