polyethylene core aluminium composite panels

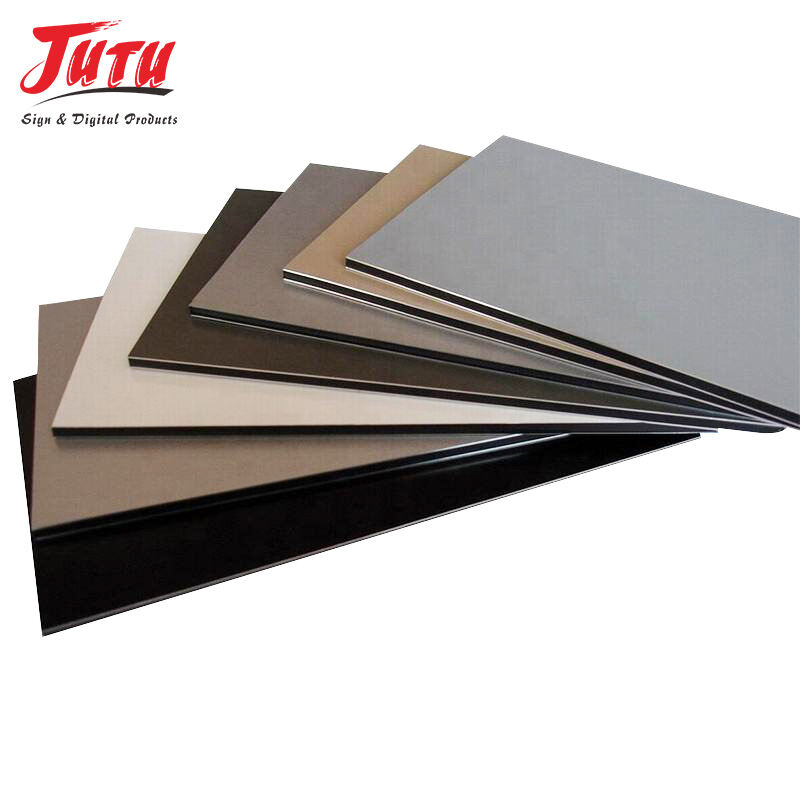

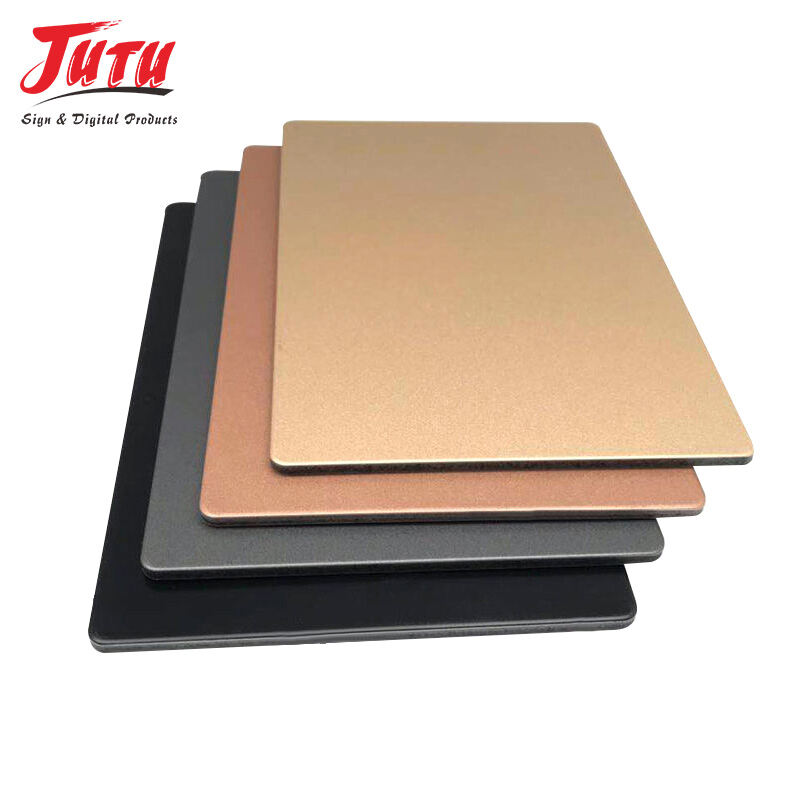

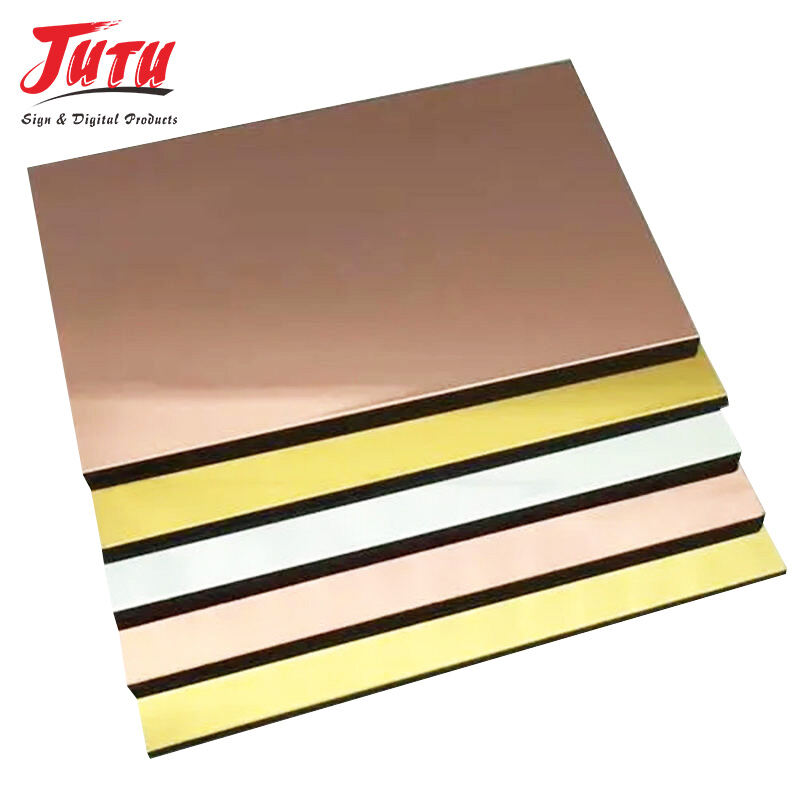

Polyethylene core aluminium composite panels represent a revolutionary building material that combines the strength of aluminum with the lightweight properties of polyethylene. These panels feature a sophisticated three-layer construction, consisting of two outer aluminum sheets bonded to a central polyethylene core through advanced adhesive technology. The main functions of polyethylene core aluminium composite panels include providing exceptional structural integrity while maintaining remarkable flexibility and thermal performance. These panels serve as versatile cladding solutions for both interior and exterior applications, offering superior weather resistance and architectural appeal. The technological features of polyethylene core aluminium composite panels encompass cutting-edge manufacturing processes that ensure consistent quality and dimensional stability. The polyethylene core acts as an insulating barrier, reducing thermal conductivity and enhancing energy efficiency in buildings. Advanced coating technologies applied to the aluminum surfaces provide enhanced durability against UV radiation, corrosion, and environmental degradation. The panel construction allows for easy fabrication and installation, supporting various forming techniques including bending, cutting, and shaping to accommodate complex architectural designs. Applications of polyethylene core aluminium composite panels span across commercial, residential, and industrial sectors. These panels are extensively used in curtain wall systems, building facades, interior partitions, signage applications, and transportation infrastructure. The construction industry particularly values these panels for their ability to create seamless, modern appearances while meeting stringent building codes and safety requirements. Healthcare facilities utilize polyethylene core aluminium composite panels for their hygienic properties and ease of maintenance. Educational institutions benefit from their acoustic properties and design flexibility. The versatility of polyethylene core aluminium composite panels makes them suitable for retrofitting existing structures and new construction projects, providing architects and designers with unlimited creative possibilities while ensuring long-term performance and cost-effectiveness.