aluminum panel suppliers

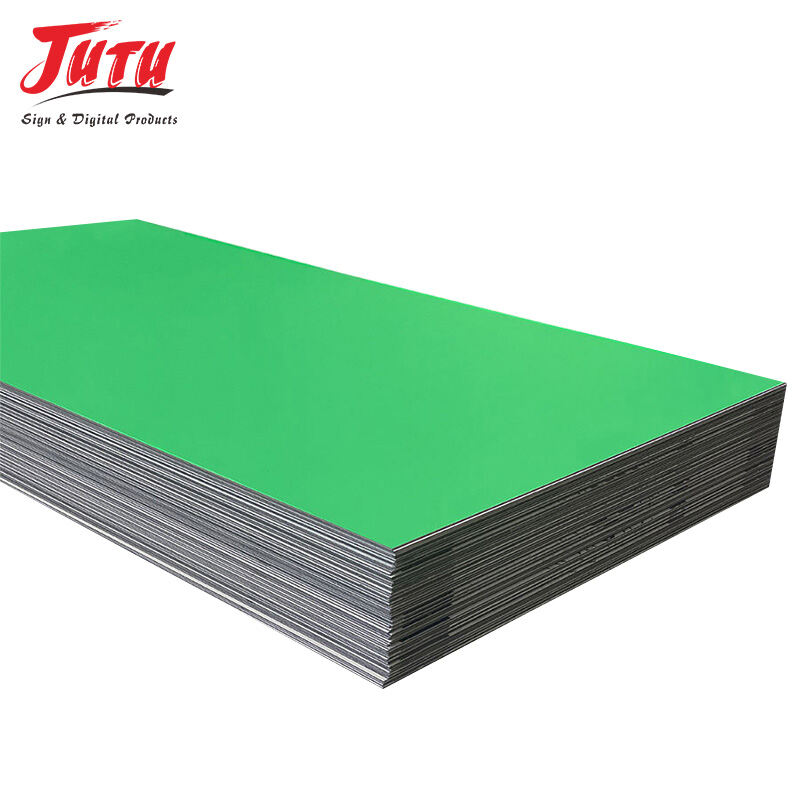

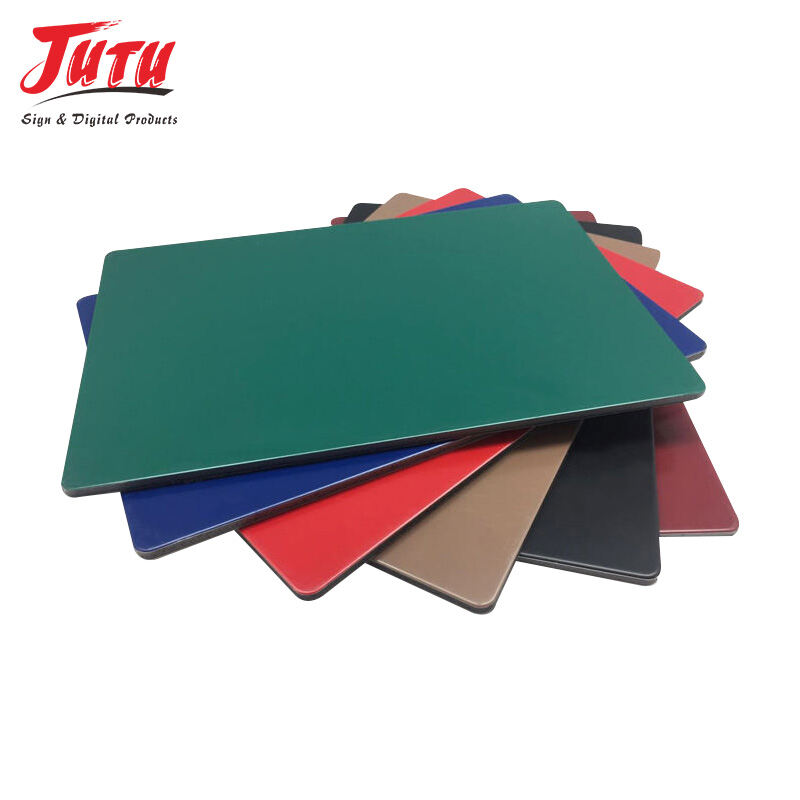

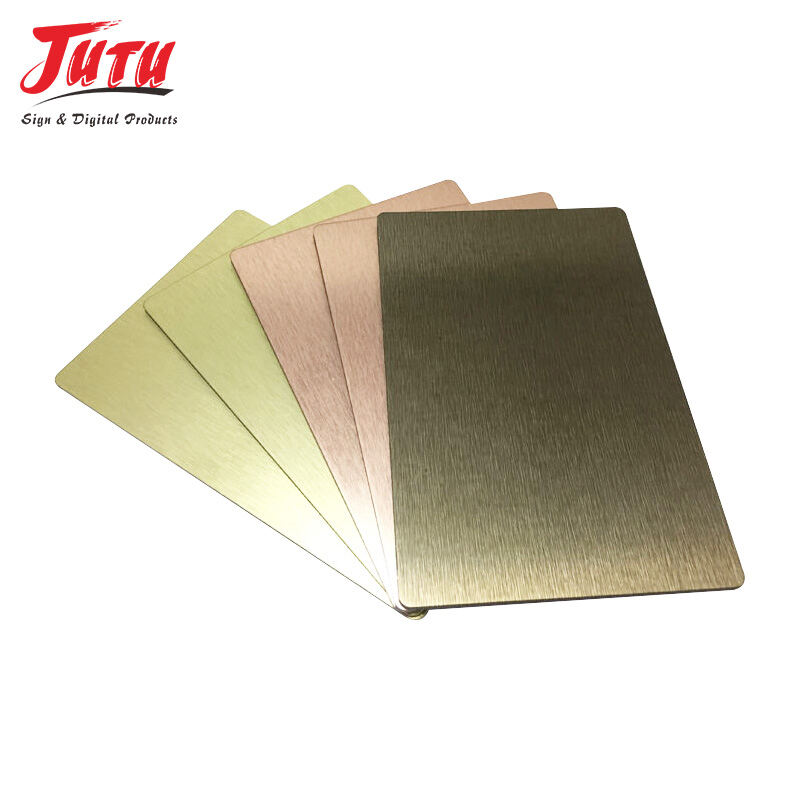

Aluminum panel suppliers represent a crucial segment of the modern construction and manufacturing industry, serving as essential partners for businesses requiring high-quality aluminum solutions. These specialized companies focus on producing and distributing aluminum panels that meet diverse industrial, architectural, and commercial needs. The primary function of aluminum panel suppliers involves manufacturing lightweight yet durable aluminum sheets, plates, and custom-formed panels that serve multiple applications across various sectors. Their technological expertise encompasses advanced rolling mills, precision cutting equipment, and sophisticated surface treatment facilities that ensure consistent quality and dimensional accuracy. Modern aluminum panel suppliers utilize state-of-the-art anodizing processes, powder coating technologies, and chemical treatment methods to enhance corrosion resistance and aesthetic appeal. The manufacturing capabilities typically include custom sizing, thickness variations ranging from thin sheets to heavy plates, and specialized alloy compositions tailored to specific performance requirements. Quality aluminum panel suppliers maintain comprehensive inventory management systems, ensuring rapid delivery and consistent supply chain reliability. Their technical teams provide engineering support, helping customers select appropriate grades, finishes, and specifications for optimal performance in intended applications. The industry has evolved to incorporate sustainable practices, with many aluminum panel suppliers emphasizing recycling programs and environmentally responsible production methods. These companies serve diverse markets including aerospace, automotive, marine, construction, signage, and electronics industries. Their distribution networks often span multiple regions, providing local support while maintaining centralized quality control standards. Advanced aluminum panel suppliers invest heavily in research and development, continuously improving alloy formulations, surface treatments, and manufacturing processes. They typically offer value-added services such as custom fabrication, precision machining, and specialized packaging solutions. The technological infrastructure of leading suppliers includes computerized inventory systems, automated cutting lines, and quality assurance laboratories that ensure every panel meets stringent industry standards and customer specifications.