aluminum composite panel 4x8 sheets

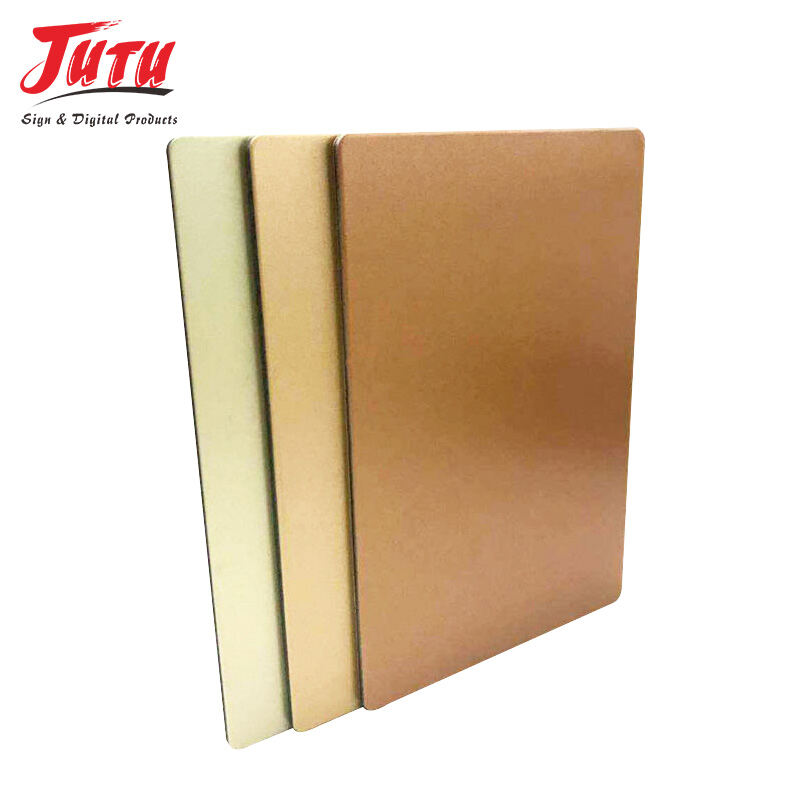

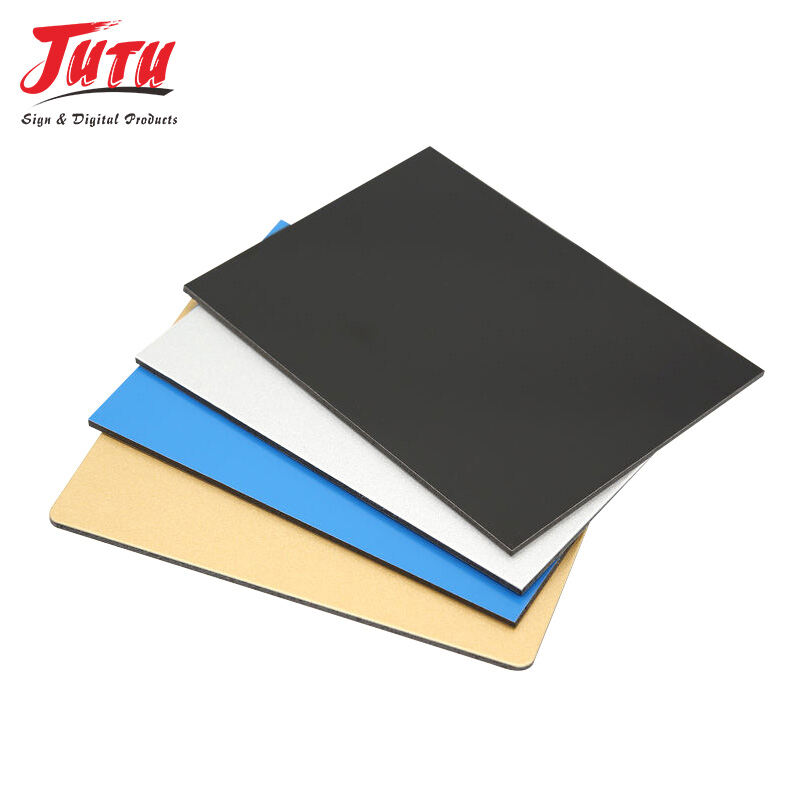

Aluminum composite panel 4x8 sheets represent a revolutionary building material that combines lightweight construction with exceptional durability and aesthetic appeal. These panels consist of two thin aluminum layers bonded to a polyethylene core, creating a sandwich structure that delivers superior performance across various construction and architectural applications. The standard 4x8 feet dimensions make aluminum composite panel 4x8 sheets perfectly suited for commercial facades, interior design projects, and industrial installations where consistent sizing and reliable performance are essential. The technological foundation of these panels relies on advanced bonding techniques that ensure the aluminum skins remain permanently attached to the core material, preventing delamination even under extreme weather conditions. This construction method results in panels that maintain their structural integrity while offering excellent thermal insulation properties and sound dampening characteristics. The manufacturing process incorporates precision cutting and forming capabilities, allowing aluminum composite panel 4x8 sheets to be fabricated into complex shapes and configurations without compromising their fundamental strength properties. Surface treatments available for these panels include PVDF coatings, polyester finishes, and specialized protective layers that enhance weather resistance and color retention over extended periods. The core material selection varies based on specific application requirements, with fire-retardant options available for projects demanding enhanced safety standards. Installation procedures for aluminum composite panel 4x8 sheets have been streamlined through innovative mounting systems that reduce labor costs while ensuring secure attachment to various substrate materials. Quality control measures during manufacturing guarantee consistent thickness, flatness, and surface finish across all panels, enabling seamless integration into large-scale projects where visual uniformity is paramount.