acp panel board

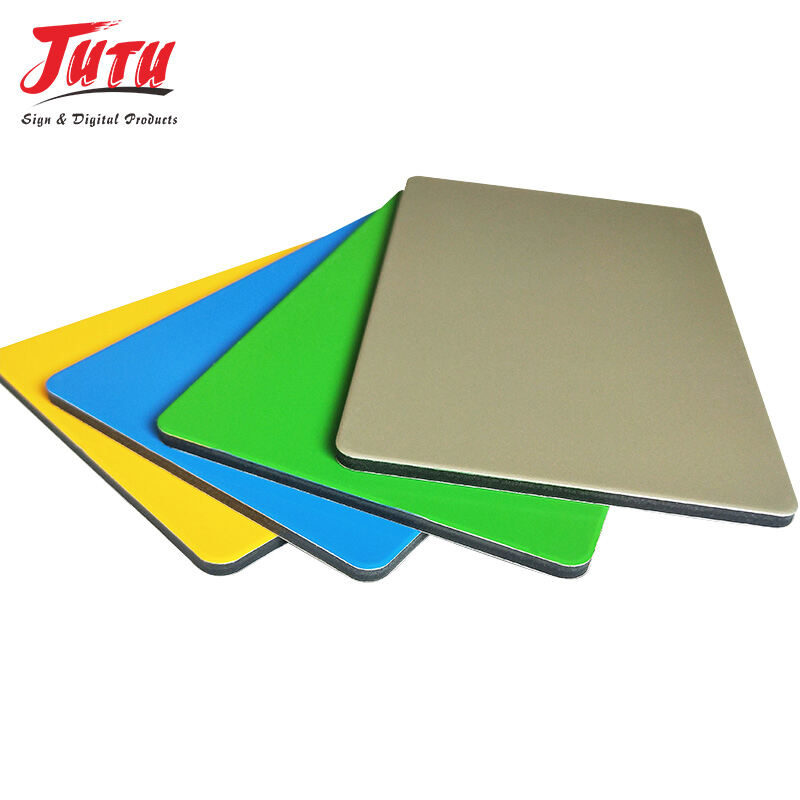

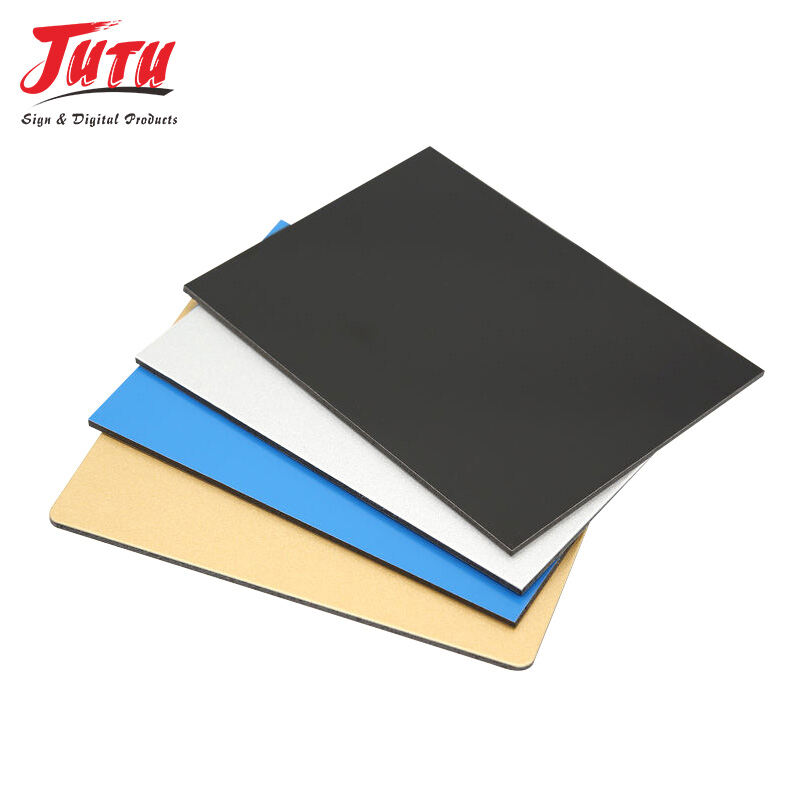

An acp panel board represents a revolutionary building material that combines aluminum composite panel technology with exceptional structural integrity and aesthetic appeal. This innovative construction solution consists of two thin aluminum sheets bonded to a polyethylene core, creating a lightweight yet remarkably strong panel system. The acp panel board delivers outstanding performance across residential, commercial, and industrial applications, making it a preferred choice for architects and builders worldwide. The primary functions of an acp panel board include providing weather-resistant exterior cladding, creating attractive interior wall systems, and offering reliable signage solutions. These panels excel in protecting buildings from environmental elements while maintaining their visual appeal over extended periods. The technological features of acp panel board systems include advanced coating technologies that resist fading, chalking, and weathering. The aluminum surfaces undergo specialized treatments that enhance durability and provide superior adhesion for various finishes. Manufacturing processes ensure consistent thickness, flatness, and dimensional stability across all panel dimensions. The polyethylene core contributes to excellent thermal insulation properties while reducing overall weight compared to solid metal alternatives. Fire-resistant variants incorporate mineral-filled cores that meet stringent building safety standards. Applications for acp panel board span numerous industries and project types. Commercial buildings utilize these panels for curtain wall systems, storefront installations, and exterior renovation projects. Residential applications include accent walls, kitchen backsplashes, and modern facade treatments. Industrial facilities benefit from the chemical resistance and easy maintenance characteristics. Signage companies appreciate the flat surface and excellent printability for creating professional displays. Transportation infrastructure projects employ acp panel board for tunnel linings, sound barriers, and station cladding. The versatility of acp panel board makes it suitable for both new construction and retrofit applications, providing designers with unlimited creative possibilities while ensuring long-term performance and cost-effectiveness.