acrylic sheet manufacturer

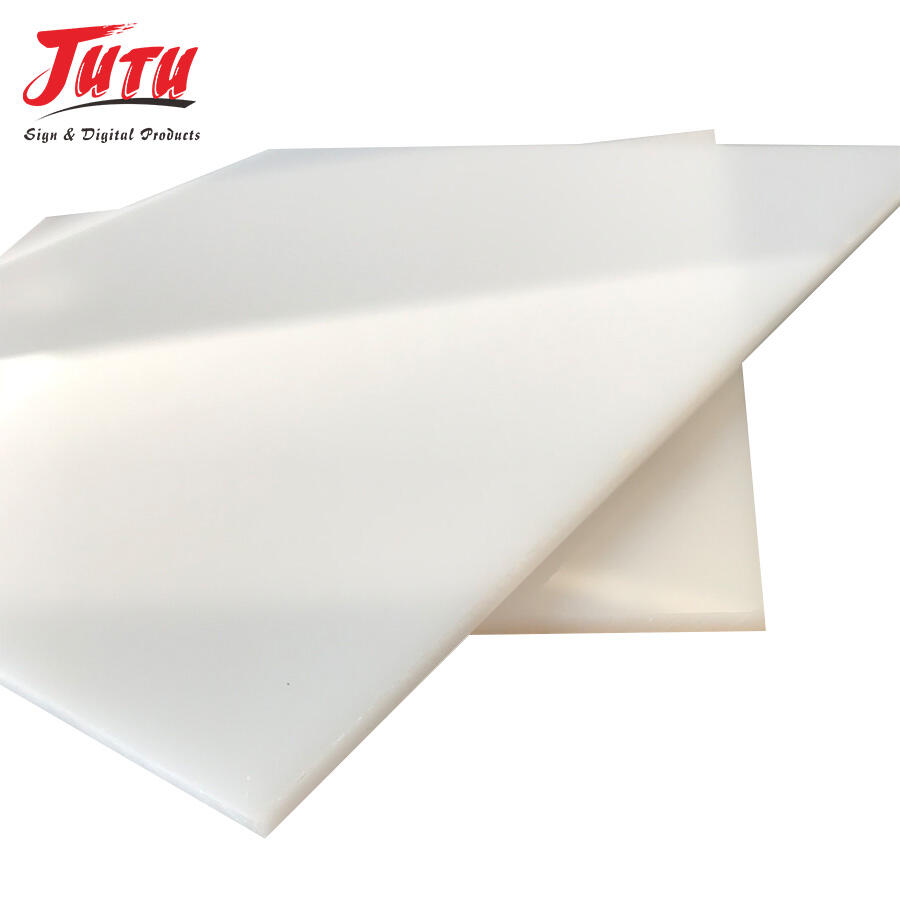

An acrylic sheet manufacturer represents a specialized industrial enterprise that produces high-quality polymethyl methacrylate (PMMA) sheets through advanced manufacturing processes. These manufacturers utilize sophisticated extrusion and casting techniques to create transparent, durable, and versatile plastic sheets that serve as superior alternatives to traditional glass materials. The primary function of an acrylic sheet manufacturer involves transforming raw acrylic resin into finished sheets through controlled heating, molding, and cooling processes that ensure consistent thickness, optical clarity, and structural integrity. Modern acrylic sheet manufacturers employ cutting-edge technology including computer-controlled extrusion lines, precision temperature monitoring systems, and automated quality control mechanisms that guarantee product consistency and reliability. The technological features of contemporary manufacturing facilities include multi-layer co-extrusion capabilities, UV-resistant coating applications, and custom color formulation systems that enable production of sheets with specific properties tailored to diverse industrial requirements. These manufacturers produce sheets in various thicknesses ranging from thin films to thick structural panels, accommodating applications spanning architectural glazing, automotive components, signage systems, retail displays, medical equipment housings, and protective barriers. The manufacturing process incorporates stringent quality control measures including optical clarity testing, impact resistance evaluation, and dimensional accuracy verification to ensure each acrylic sheet meets international standards and customer specifications. Advanced acrylic sheet manufacturers also offer value-added services such as custom cutting, edge polishing, drilling, and thermoforming capabilities that provide complete solutions for end-users. The applications of manufactured acrylic sheets extend across multiple industries including construction, automotive, aerospace, electronics, healthcare, and consumer goods sectors, where their superior optical properties, weather resistance, and fabrication flexibility make them indispensable materials for innovative product development and architectural solutions.