acrylite sheet manufacturer

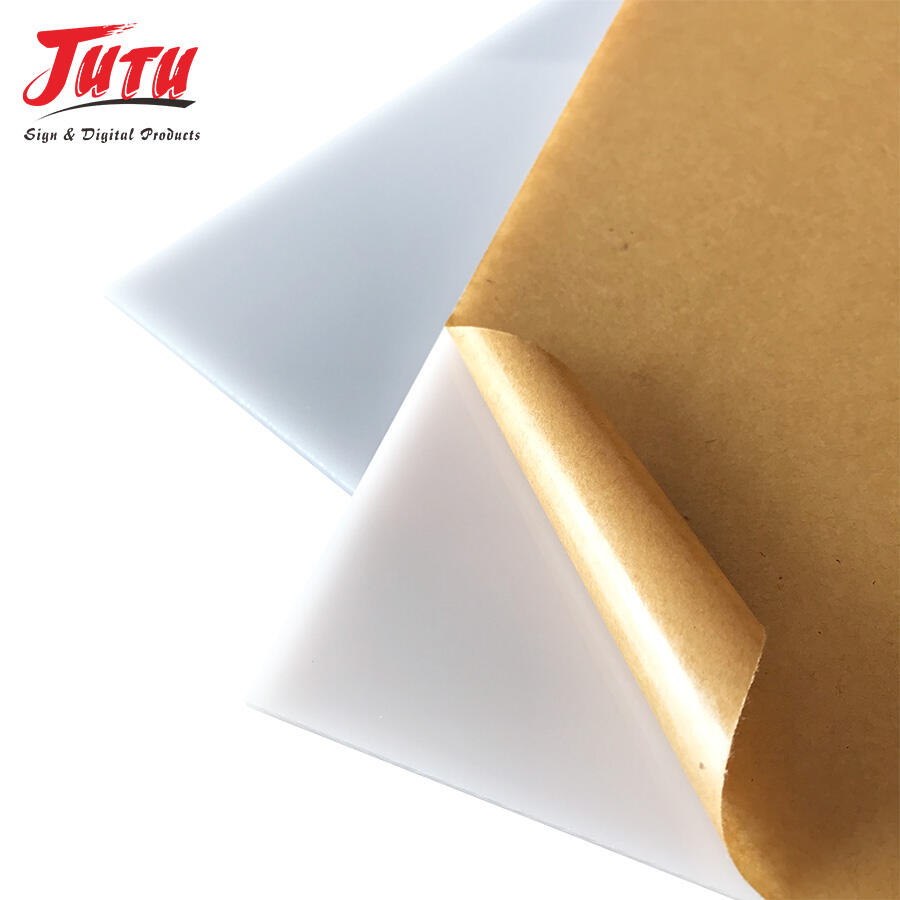

An acrylite sheet manufacturer stands at the forefront of advanced thermoplastic production, specializing in creating high-quality acrylic sheets that serve countless industries worldwide. These specialized manufacturers operate sophisticated facilities equipped with cutting-edge extrusion and casting technologies to produce crystal-clear, durable acrylic materials. The primary function of an acrylite sheet manufacturer involves transforming raw acrylic polymers into versatile sheets through precise temperature control, pressure management, and quality monitoring systems. Modern acrylite sheet manufacturer facilities utilize computer-controlled production lines that ensure consistent thickness, optical clarity, and structural integrity across every product batch. The technological features employed by leading acrylite sheet manufacturer companies include multi-layer co-extrusion capabilities, UV stabilization processes, and specialized surface treatments that enhance performance characteristics. These manufacturers implement rigorous quality control protocols, including laser thickness measurement, optical clarity testing, and stress analysis to guarantee premium products. Applications for products from an acrylite sheet manufacturer span numerous sectors including architectural glazing, automotive components, medical equipment, display systems, and protective barriers. The versatility of acrylic sheets makes them essential for outdoor signage, aquarium construction, aircraft windows, and decorative installations. Advanced acrylite sheet manufacturer operations often incorporate recycling programs, sustainable production methods, and energy-efficient manufacturing processes to minimize environmental impact while maintaining superior product quality. The continuous innovation in production techniques allows these manufacturers to develop specialized grades including impact-modified, flame-retardant, and anti-static variants. Modern acrylite sheet manufacturer facilities also offer custom fabrication services, precision cutting, and value-added processing to meet specific customer requirements across diverse market segments.