acrylic glass sheets manufacturer

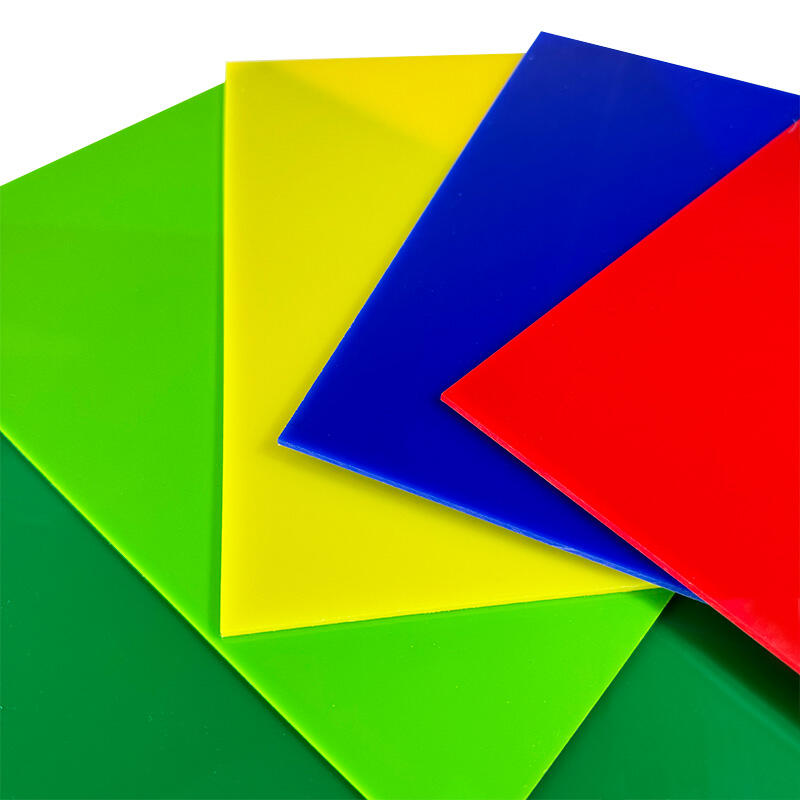

An acrylic glass sheets manufacturer represents a specialized industrial entity dedicated to producing high-quality transparent thermoplastic materials that serve as superior alternatives to traditional glass. These manufacturers utilize advanced polymer chemistry and precision manufacturing techniques to create versatile sheets that combine optical clarity with exceptional durability. The primary function of an acrylic glass sheets manufacturer involves transforming raw acrylic polymer resins through sophisticated processes including extrusion, casting, and molding to produce sheets of varying thicknesses, sizes, and specifications. The technological features employed by modern acrylic glass sheets manufacturers include computer-controlled production lines that ensure consistent thickness tolerances, advanced surface treatment capabilities for enhanced scratch resistance, and specialized UV stabilization processes that prevent yellowing and degradation over time. These manufacturers implement rigorous quality control systems featuring optical clarity testing, impact resistance evaluation, and dimensional accuracy verification. The production facilities typically incorporate clean room environments to minimize contamination and ensure pristine surface finishes. Applications for products from acrylic glass sheets manufacturers span numerous industries including construction for glazing applications, automotive for windshields and windows, marine industry for boat windows and hatches, signage and display manufacturing, architectural elements such as skylights and decorative panels, medical equipment housings, and protective barriers. The versatility of acrylic sheets makes them ideal for both interior and exterior applications where transparency, weather resistance, and impact strength are crucial requirements. Modern acrylic glass sheets manufacturers also focus on sustainable production methods, incorporating recycling programs and energy-efficient manufacturing processes. They offer customization services including precision cutting, drilling, bending, and surface treatments to meet specific customer requirements. The technological advancement in manufacturing processes allows these companies to produce sheets with enhanced properties such as improved impact resistance, better optical clarity, and specialized features like anti-reflective coatings or colored variants while maintaining cost-effectiveness compared to traditional glass alternatives.