plexiglass acrylic sheets manufacturer

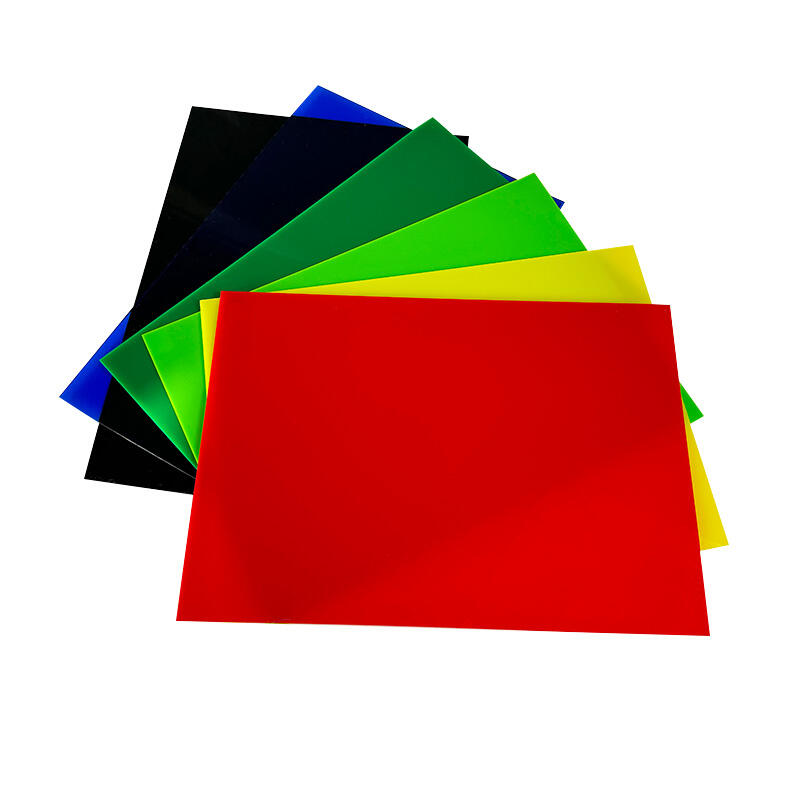

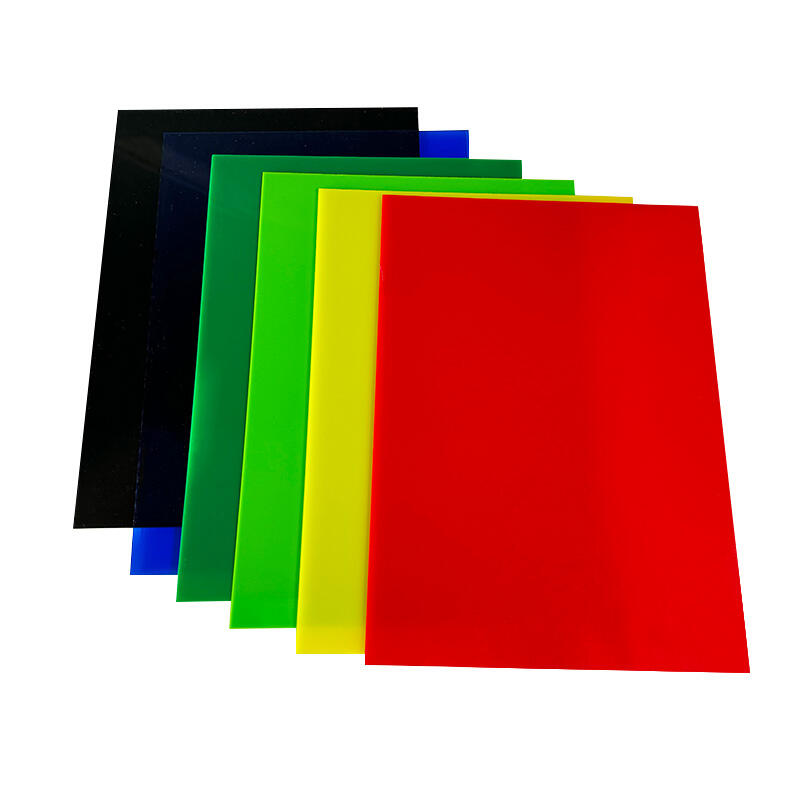

A plexiglass acrylic sheets manufacturer represents a specialized industrial entity that produces high-quality transparent thermoplastic materials used across diverse industries worldwide. These manufacturers utilize advanced polymerization processes to create polymethyl methacrylate (PMMA) sheets that offer exceptional optical clarity, durability, and versatility. The core function of a plexiglass acrylic sheets manufacturer involves transforming raw methyl methacrylate monomers into solid, transparent sheets through sophisticated chemical reactions and precise manufacturing controls. Modern manufacturing facilities employ state-of-the-art extrusion and casting technologies to produce sheets in various thicknesses, sizes, and specifications. The technological infrastructure includes computer-controlled mixing systems, temperature-regulated polymerization chambers, and precision cutting equipment that ensures consistent product quality. Advanced quality control laboratories test each batch for optical properties, impact resistance, chemical stability, and dimensional accuracy. The manufacturing process begins with monomer preparation, followed by catalyzed polymerization under controlled atmospheric conditions. Manufacturers utilize specialized cooling systems and annealing processes to eliminate internal stresses and achieve optimal material properties. Digital monitoring systems track production parameters in real-time, ensuring adherence to international standards such as ISO 9001 and ASTM specifications. These facilities often incorporate environmentally sustainable practices, including solvent recovery systems and energy-efficient heating technologies. The applications for manufactured plexiglass acrylic sheets span numerous sectors including construction, automotive, aerospace, marine, retail displays, medical equipment, and architectural glazing. In construction, these sheets serve as skylights, protective barriers, and decorative elements. The automotive industry utilizes them for headlight lenses, instrument panels, and protective covers. Aerospace applications include aircraft windows, interior panels, and cockpit displays. A reputable plexiglass acrylic sheets manufacturer maintains extensive inventory capabilities, custom cutting services, and technical support teams to assist customers with material selection and application guidance. The manufacturing process incorporates rigorous testing protocols to verify weather resistance, UV stability, and long-term performance characteristics essential for outdoor applications.