acrylic board manufacturer

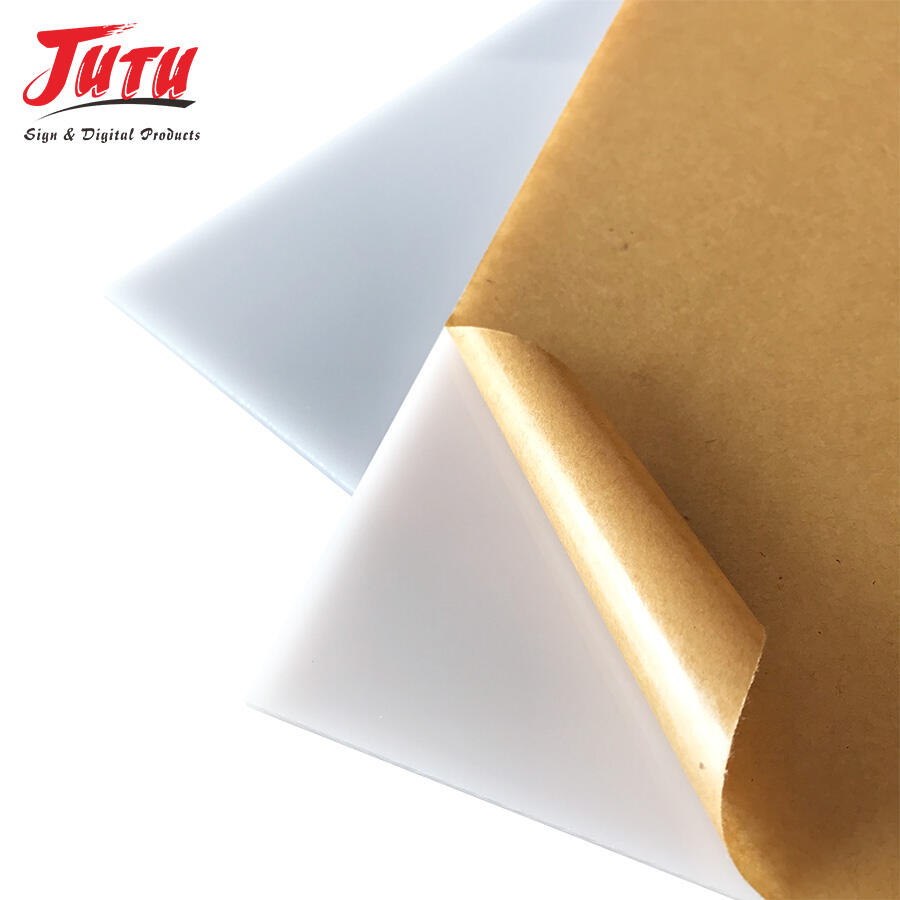

An acrylic board manufacturer represents a specialized industrial entity that produces high-quality acrylic sheets through advanced manufacturing processes. These manufacturers utilize cutting-edge technology to transform raw acrylic materials into versatile, durable boards that serve countless applications across diverse industries. The primary function of an acrylic board manufacturer involves the precise molding, cutting, and finishing of acrylic materials to create boards with specific dimensions, thickness, and optical properties. These manufacturers employ sophisticated extrusion techniques, where acrylic polymers are heated and shaped through specialized machinery to achieve consistent quality and dimensional accuracy. The technological features of modern acrylic board manufacturers include automated production lines, computer-controlled cutting systems, and advanced quality control mechanisms that ensure each board meets stringent industry standards. Temperature-controlled environments maintain optimal conditions throughout the manufacturing process, preventing warping or optical distortions that could compromise product integrity. Surface treatment technologies enable manufacturers to produce boards with various finishes, from crystal-clear transparency to frosted textures or colored variations. Quality assurance protocols incorporate optical clarity testing, stress analysis, and dimensional verification to guarantee superior performance. Applications for acrylic boards span numerous sectors including signage, display cases, architectural glazing, furniture components, protective barriers, and artistic installations. The automotive industry relies on acrylic boards for dashboard components and light covers, while the medical field utilizes them for equipment housings and sterile barriers. Retail environments benefit from acrylic boards in product displays, shelf dividers, and promotional materials. Educational institutions use these boards for whiteboards, notice boards, and protective screens. The versatility of acrylic board manufacturers enables customization for specific client requirements, including unique shapes, sizes, colors, and optical properties. Modern manufacturers also focus on sustainability, implementing recycling programs and eco-friendly production methods to minimize environmental impact while maintaining exceptional product quality and performance standards.