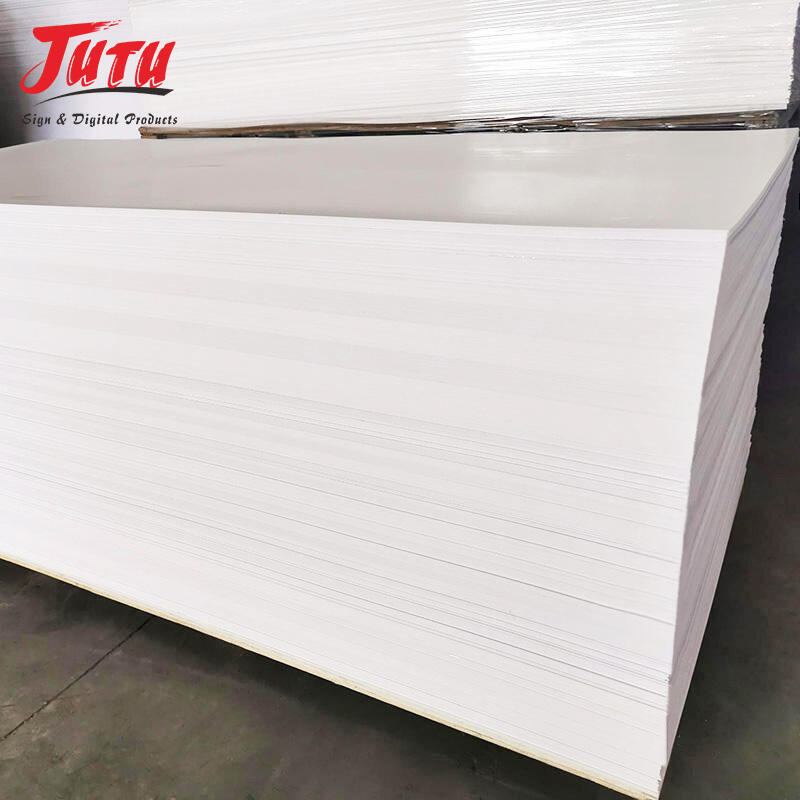

pvc plastic foam board

PVC plastic foam board represents a revolutionary advancement in lightweight construction materials, combining exceptional performance with remarkable versatility. This innovative material consists of expanded polyvinyl chloride that undergoes a specialized foaming process, creating a cellular structure that delivers outstanding strength-to-weight ratios. The manufacturing process involves heating PVC resin with foaming agents, resulting in a closed-cell foam structure that provides superior insulation properties and dimensional stability. PVC plastic foam board exhibits excellent resistance to moisture, chemicals, and UV radiation, making it suitable for both interior and exterior applications. The material maintains consistent performance across temperature variations, from -20°C to +60°C, ensuring reliable functionality in diverse climates. Its non-toxic composition and recyclable nature align with environmental sustainability requirements. The board's smooth surface finish accepts various printing techniques, adhesives, and coatings, enabling customization for specific project needs. Available in multiple thicknesses ranging from 1mm to 30mm, PVC plastic foam board accommodates different structural requirements and design specifications. The material's fire-retardant properties meet international safety standards, providing additional security for commercial and residential installations. Its easy machinability allows for precise cutting, drilling, and shaping using standard woodworking tools, reducing installation complexity and labor costs. The board's excellent thermal insulation properties contribute to energy efficiency in building applications, while its sound-dampening characteristics enhance acoustic comfort. PVC plastic foam board serves multiple industries including signage, construction, marine applications, furniture manufacturing, and exhibition displays. The material's resistance to warping, cracking, and delamination ensures long-term performance and reduces maintenance requirements, making it a cost-effective solution for demanding applications.