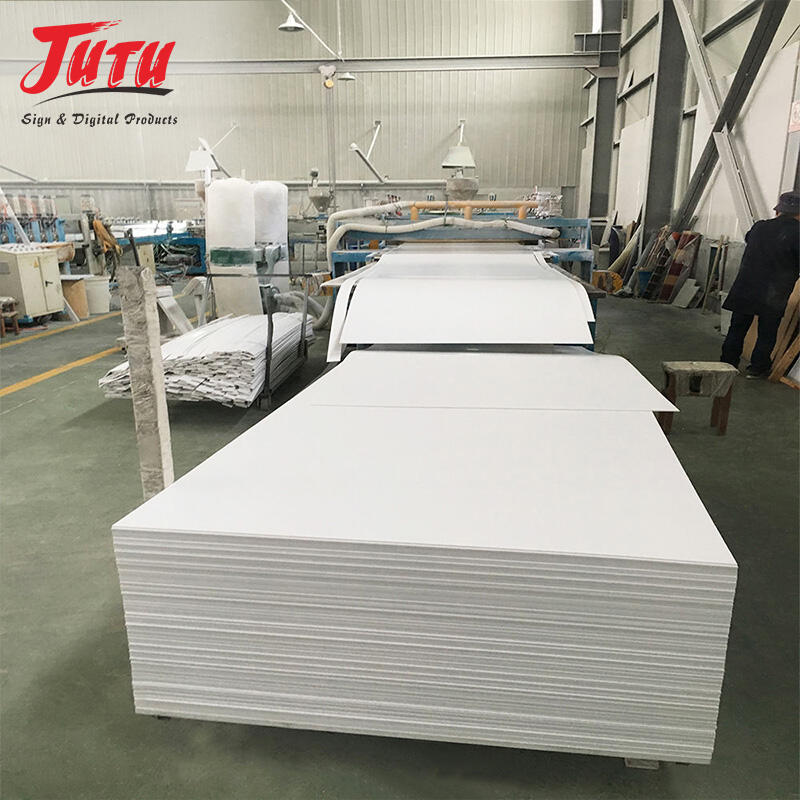

12 mm pvc board

The 12 mm PVC board represents a versatile and robust building material that has gained widespread recognition in construction, interior design, and industrial applications. This medium-thickness polyvinyl chloride panel offers an optimal balance between structural strength and workability, making it an ideal choice for professionals and DIY enthusiasts alike. The 12 mm PVC board features exceptional dimensional stability, maintaining its shape and integrity under various environmental conditions without warping, swelling, or shrinking like traditional wood materials. Its closed-cell foam structure provides excellent insulation properties while keeping the weight significantly lower than conventional building materials. The board's smooth, uniform surface accepts various finishing techniques including painting, laminating, and vinyl wrapping, allowing for endless design possibilities. Technologically, the 12 mm PVC board incorporates advanced polymer chemistry that creates a material resistant to moisture, chemicals, and UV radiation. The manufacturing process involves precise extrusion techniques that ensure consistent thickness and density throughout each panel. This construction method eliminates internal voids and weak spots common in other composite materials. The board's fire-retardant properties meet stringent safety standards, making it suitable for commercial and residential applications. Its thermal expansion coefficient remains minimal, ensuring stable performance across temperature fluctuations. The 12 mm PVC board finds extensive use in cabinet making, furniture construction, wall cladding, ceiling systems, and marine applications where moisture resistance is crucial. Architects specify this material for partition walls, decorative panels, and exterior facades due to its weather resistance and low maintenance requirements. The construction industry values the 12 mm PVC board for temporary structures, formwork, and hoarding applications where durability and reusability are essential factors.