marine pvc foam board

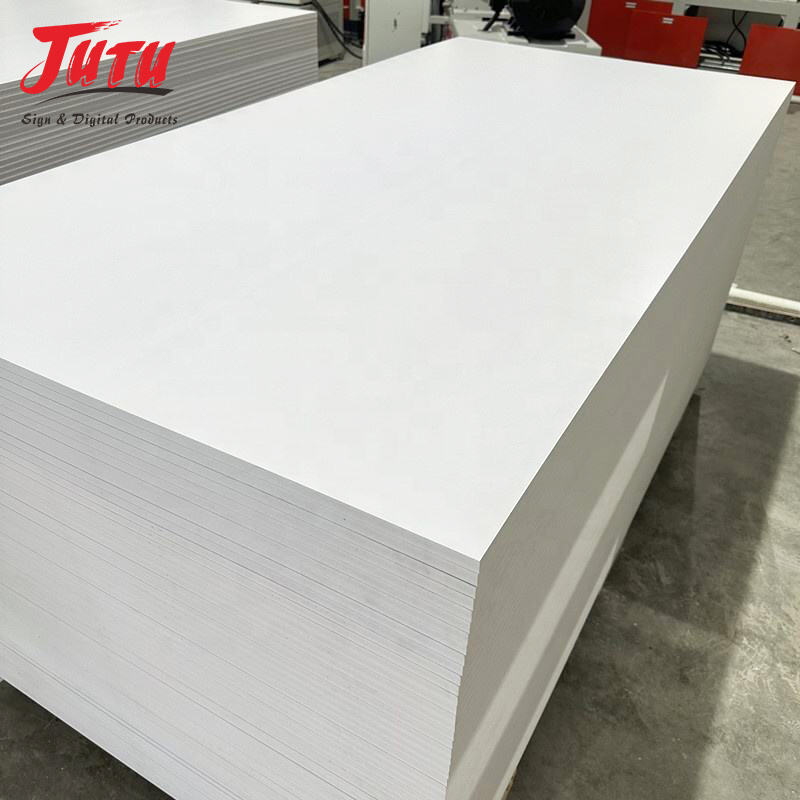

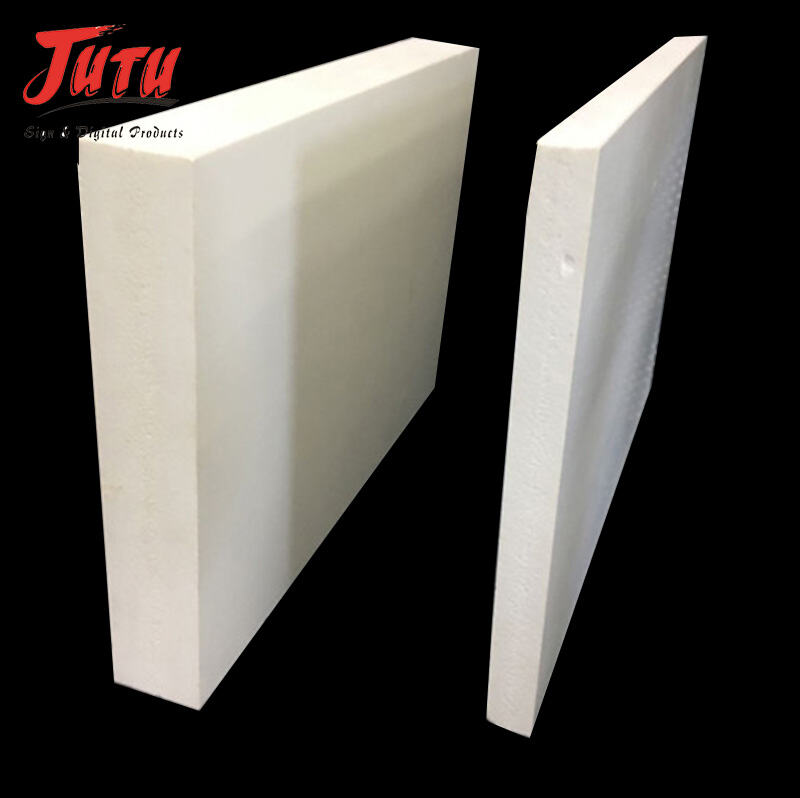

Marine PVC foam board represents a revolutionary advancement in marine construction materials, offering exceptional performance characteristics that make it the preferred choice for boat builders, marine engineers, and watercraft enthusiasts worldwide. This closed-cell foam core material features a rigid PVC structure that delivers outstanding strength-to-weight ratios while maintaining excellent buoyancy properties essential for marine applications. The marine PVC foam board is manufactured through an advanced extrusion process that creates a uniform cellular structure, resulting in consistent density and mechanical properties throughout the entire panel. The technological features of marine PVC foam board include superior water resistance, dimensional stability, and chemical inertness that prevents degradation in harsh marine environments. Its closed-cell structure prevents water absorption, ensuring that the material maintains its structural integrity and insulation properties even when exposed to prolonged moisture conditions. The board exhibits excellent machinability, allowing for precise cutting, shaping, and routing operations using standard woodworking tools. Marine PVC foam board applications span across various sectors including yacht construction, commercial shipbuilding, recreational boat manufacturing, and marine infrastructure development. In yacht construction, this versatile material serves as core material for sandwich composite construction, providing structural support while reducing overall vessel weight. Commercial shipbuilders utilize marine PVC foam board for deck applications, interior paneling, and insulation systems due to its fire-retardant properties and compliance with international marine safety standards. The material's versatility extends to recreational boat manufacturing where it functions as flotation foam, structural reinforcement, and decorative elements. Marine infrastructure projects benefit from the board's durability and weather resistance, making it suitable for dock construction, marina facilities, and coastal protection systems.