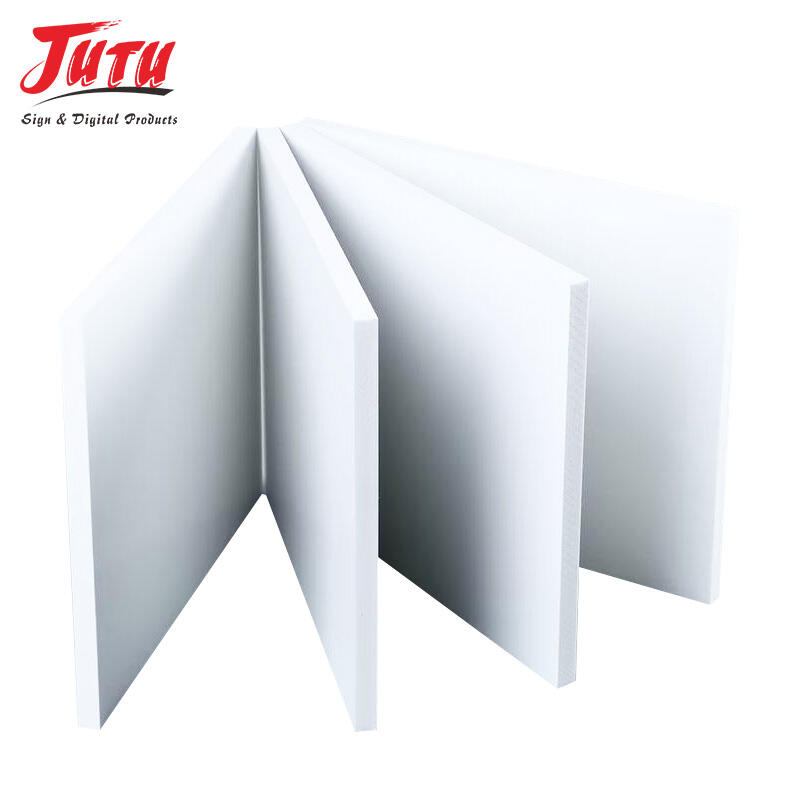

Versatile Fabrication and Installation Capabilities

The 15mm pvc foam sheet offers exceptional fabrication flexibility that enables custom solutions for diverse applications while maintaining ease of installation across various project types. Standard woodworking tools effectively cut, drill, route, and shape this material, eliminating the need for specialized equipment or extensive operator training. The material machines cleanly without generating hazardous dust or requiring special ventilation systems, improving workplace safety and environmental compliance. Cutting operations produce smooth edges that require minimal finishing, reducing fabrication time and material waste compared to alternatives that generate rough or damaged edge conditions. The 15mm pvc foam sheet accepts various joining methods including mechanical fasteners, structural adhesives, and thermal welding techniques, providing design flexibility for different connection requirements. Thermoforming capabilities allow complex three-dimensional shapes to be created for specialized applications, expanding design possibilities beyond flat sheet configurations. The material maintains dimensional stability during fabrication operations, preventing warping, twisting, or distortion that could compromise fit and finish quality. Surface preparation requirements are minimal, as the smooth factory finish accepts paints, coatings, and laminated materials directly without extensive preparation steps. The 15mm pvc foam sheet demonstrates excellent screw and fastener retention properties, ensuring reliable mechanical connections without pull-through or strip-out failures. Installation efficiency improves significantly due to the lightweight nature and ease of handling, allowing single-person installation for most applications. The material flexibility accommodates building movement and thermal expansion without cracking or joint failure, reducing maintenance requirements over the service life. Custom sizing and shaping can be performed on-site using portable tools, eliminating delays associated with factory fabrication and shipping. The 15mm pvc foam sheet accepts various edge treatment options including trim strips, gaskets, and sealants to create weather-tight installations. Quality assurance during fabrication is simplified by the material's consistent properties and predictable machining characteristics, reducing inspection requirements and rework incidents.