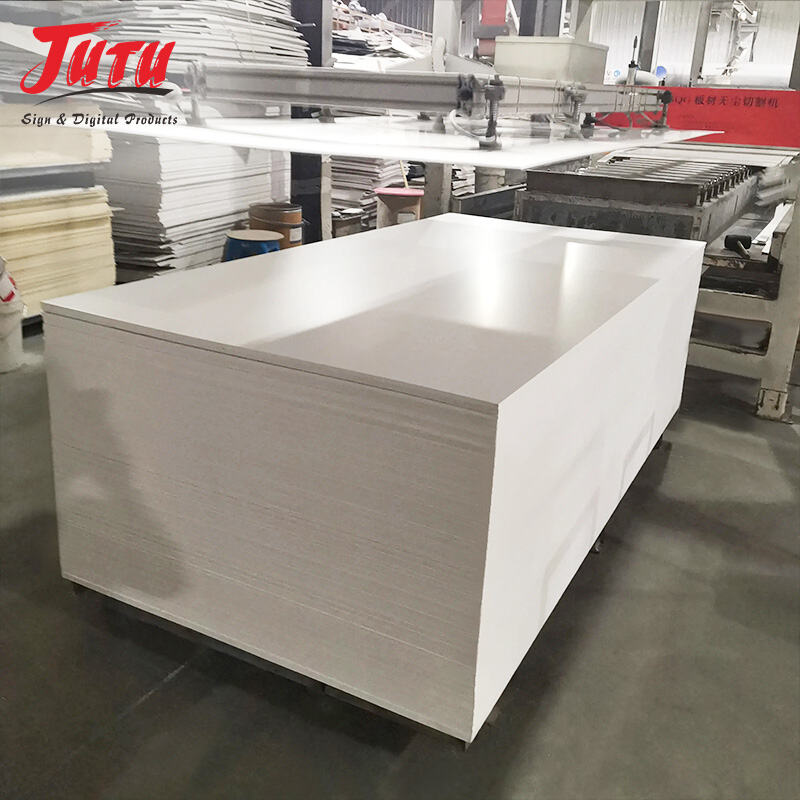

pvc foam board sheet price

PVC foam board sheet price represents an essential consideration for businesses and individuals seeking versatile, durable construction materials. These lightweight yet robust sheets combine polyvinyl chloride with specialized foaming agents to create a cellular structure that delivers exceptional performance across numerous applications. The pvc foam board sheet price varies based on thickness, density, surface finish, and manufacturing quality, making it crucial to understand the value proposition these materials offer. PVC foam boards feature closed-cell construction that provides excellent thermal insulation, moisture resistance, and dimensional stability. The manufacturing process involves precise temperature control and chemical formulation to achieve consistent density throughout each sheet. This technology ensures uniform properties that translate into reliable performance in demanding environments. The pvc foam board sheet price reflects advanced production techniques that eliminate air bubbles and create smooth, paintable surfaces suitable for diverse finishing requirements. These sheets excel in signage applications, architectural modeling, marine construction, and industrial fabrication where weight reduction without compromising strength becomes paramount. The chemical resistance of PVC foam boards makes them ideal for environments exposed to cleaning agents, mild acids, and weathering conditions. UV stabilizers incorporated during manufacturing protect against solar degradation, extending service life significantly. The pvc foam board sheet price includes these protective features that reduce long-term maintenance costs. Fabrication versatility allows cutting, drilling, routing, and thermoforming using standard woodworking tools, eliminating specialized equipment requirements. Surface treatments accommodate screen printing, digital printing, vinyl application, and conventional painting systems. The pvc foam board sheet price reflects this adaptability that streamlines project workflows and reduces installation complexity. Fire retardant formulations meet building codes while maintaining structural integrity under thermal stress, ensuring safety compliance across commercial and residential applications.