Easy Installation and Versatile Application Methods

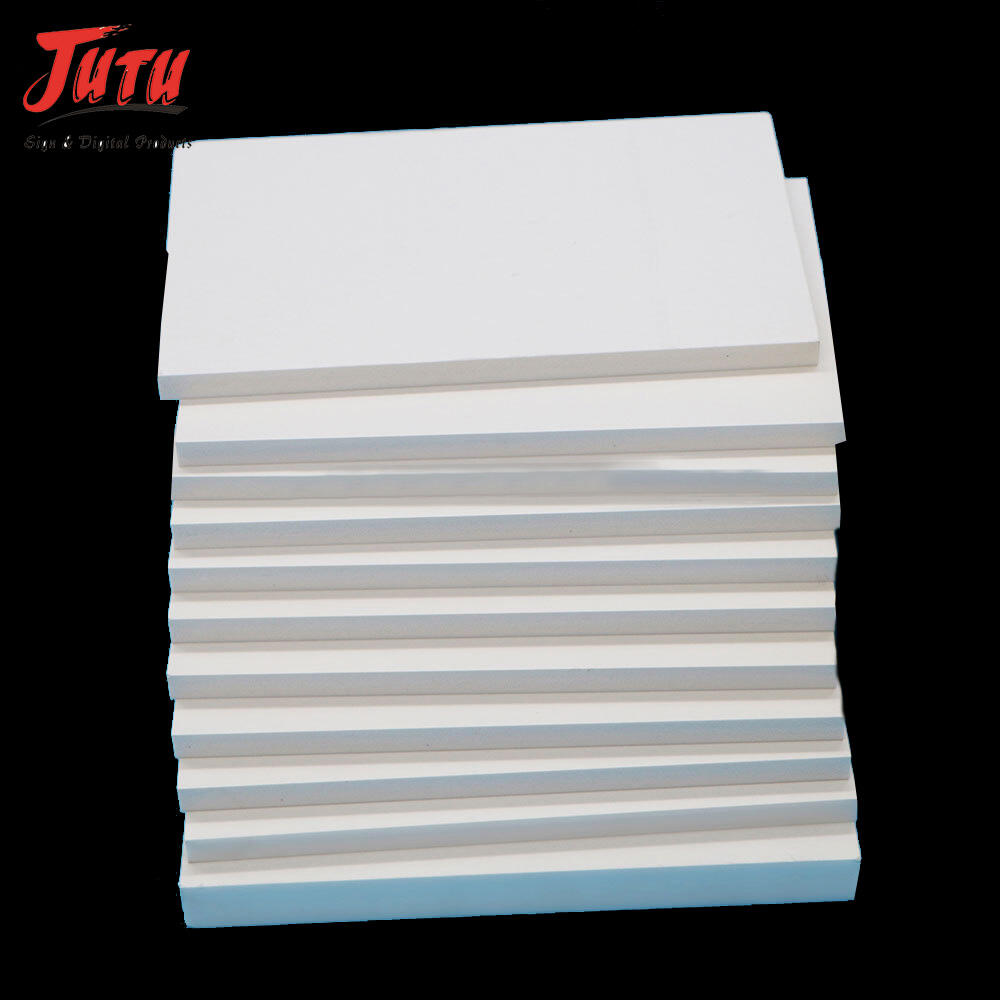

The 12mm pvc board price offers exceptional value through simplified installation processes that reduce labor costs and project timelines while accommodating diverse application methods across multiple construction scenarios. Professional contractors and DIY enthusiasts appreciate the lightweight characteristics of 12mm PVC boards, which typically weigh significantly less than equivalent thickness wood or cement-based alternatives. This weight reduction simplifies handling procedures, reduces structural load requirements, and enables single-person installation in many applications. The boards cut cleanly using standard woodworking tools including circular saws, jigsaws, and utility knives, eliminating the need for specialized equipment or diamond blades required for other building materials. Installation versatility allows 12mm PVC boards to be mounted using various methods including mechanical fasteners, construction adhesives, or combination approaches depending on specific application requirements. The material accepts screws, nails, and staples without splitting or cracking, providing reliable attachment points that maintain holding strength over extended periods. Tongue-and-groove profiles available in many 12mm PVC board products enable seamless joint connections that create continuous surfaces without visible fastener lines. This design feature proves particularly valuable for wall cladding and ceiling applications where aesthetic appearance demands smooth, uninterrupted surfaces. The 12mm pvc board price becomes more attractive considering the reduced skilled labor requirements, as basic carpentry skills suffice for successful installation in most residential and commercial applications. Cutting accuracy remains consistent throughout the material thickness, allowing precise fitting around obstacles, openings, and irregular surfaces that challenge other building materials. The boards maintain dimensional stability during installation, preventing the warping or movement that complicates installation of natural wood products. Edge finishing options include routed profiles, beveled cuts, and various trim accessories that accommodate different design requirements without additional material costs. Temperature stability during installation ensures proper fit and finish regardless of seasonal conditions, unlike materials that expand or contract significantly with temperature changes.