plastic aluminium composite panel price

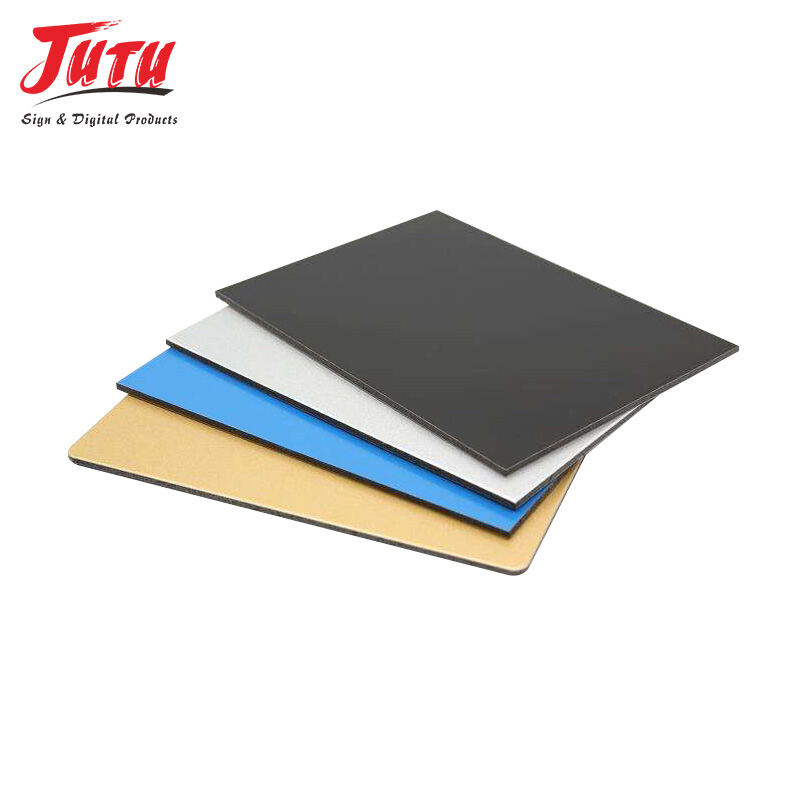

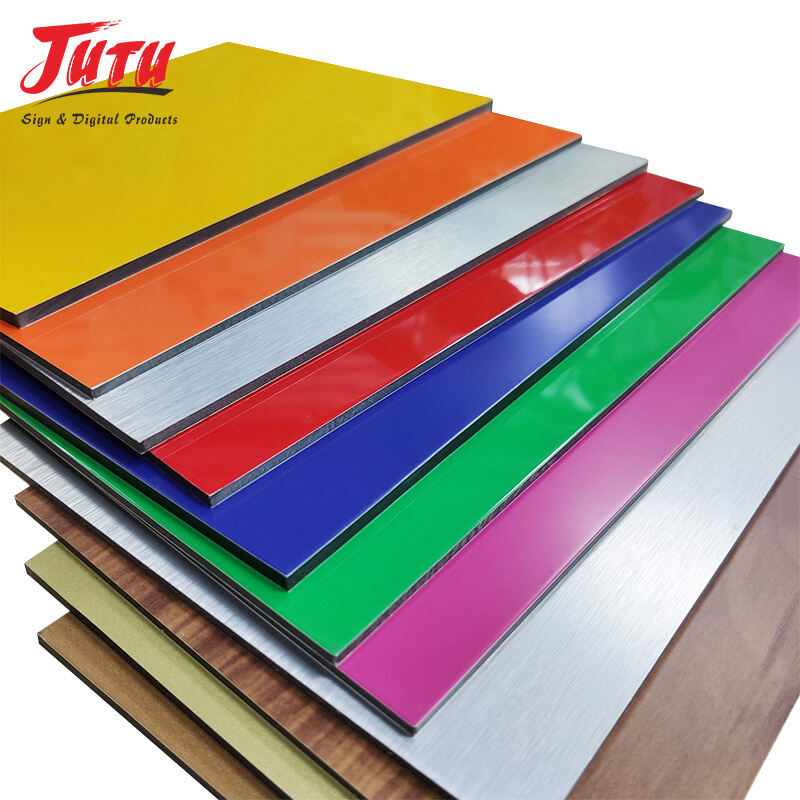

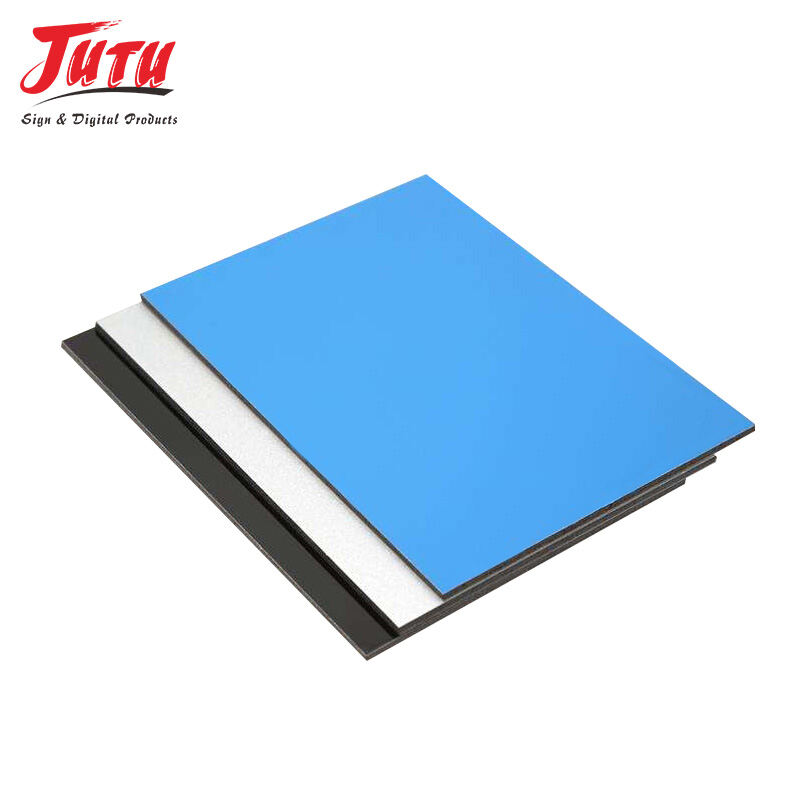

Understanding plastic aluminium composite panel price requires examining the comprehensive value proposition these innovative building materials offer. Plastic aluminium composite panels, commonly known as ACPs, represent a revolutionary approach to modern construction and architectural design. The plastic aluminium composite panel price reflects the sophisticated manufacturing process that combines lightweight polymer cores with durable aluminium outer layers, creating a versatile material that meets diverse construction requirements. These panels serve multiple functions including exterior cladding, interior decoration, signage applications, and structural enhancement. The technological features behind plastic aluminium composite panel price determination include advanced bonding techniques that ensure superior adhesion between layers, weather-resistant coatings that provide long-lasting protection, and precision manufacturing processes that guarantee consistent quality. The core technology involves thermoplastic materials sandwiched between aluminium sheets, creating exceptional strength-to-weight ratios. Applications for these panels span residential buildings, commercial complexes, industrial facilities, transportation infrastructure, and retail establishments. The plastic aluminium composite panel price varies based on specifications such as thickness, surface treatments, color options, and fire-resistance ratings. Manufacturing standards significantly influence pricing, with certified panels meeting international building codes commanding premium rates. Installation considerations also affect overall project costs, as proper mounting systems and professional installation ensure optimal performance. The versatility of these panels makes them suitable for both new construction and renovation projects, with the plastic aluminium composite panel price offering competitive advantages over traditional materials like solid aluminium, steel, or natural stone cladding systems.