Versatile Design Flexibility and Aesthetic Excellence

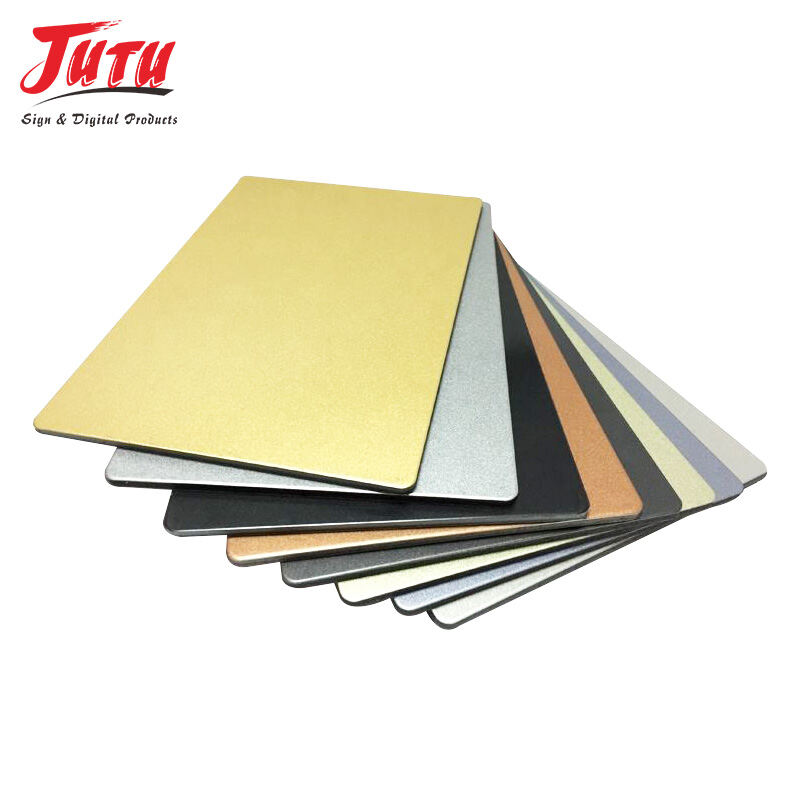

The 4mm aluminum composite panel provides unmatched design flexibility that enables architects, designers, and builders to realize their creative visions while maintaining practical functionality and performance standards. This design versatility begins with an extensive range of standard colors, finishes, and textures that accommodate virtually any aesthetic requirement. The panel surface accepts various coating systems including metallic finishes, wood grain patterns, stone textures, and custom color formulations that match specific design requirements. Digital printing capabilities transform the 4mm aluminum composite panel into a canvas for custom graphics, architectural imagery, and branding elements that create distinctive building identities. The flexibility extends to the panel's ability to be formed into curved surfaces, angles, and complex geometric shapes that would be challenging or impossible with traditional building materials. Specialized forming techniques allow the 4mm aluminum composite panel to be bent, folded, and shaped while maintaining structural integrity and surface finish quality. This formability enables the creation of radius corners, cylindrical surfaces, and sculptural architectural elements that add visual interest and functionality to building designs. Installation flexibility includes compatibility with various mounting systems, from traditional mechanical fastening to advanced structural glazing techniques that create seamless exterior surfaces. The 4mm aluminum composite panel accommodates both vertical and horizontal orientations, allowing designers to create dynamic visual patterns and textures through panel arrangement and joint detailing. Edge finishing options include factory-applied edge banding, field-applied sealants, and mechanical edge closure systems that ensure weather-tight installations while maintaining aesthetic continuity. The panel system integrates seamlessly with other building materials including glass, stone, and metal components, enabling mixed-material facades that showcase design creativity. Lighting integration capabilities allow for backlighting effects that transform the 4mm aluminum composite panel into illuminated architectural features for dramatic nighttime presentations. Maintenance considerations support long-term aesthetic performance through surface treatments that resist staining, graffiti, and environmental soiling while enabling easy cleaning and restoration procedures.