Exceptional Design Flexibility and Aesthetic Versatility

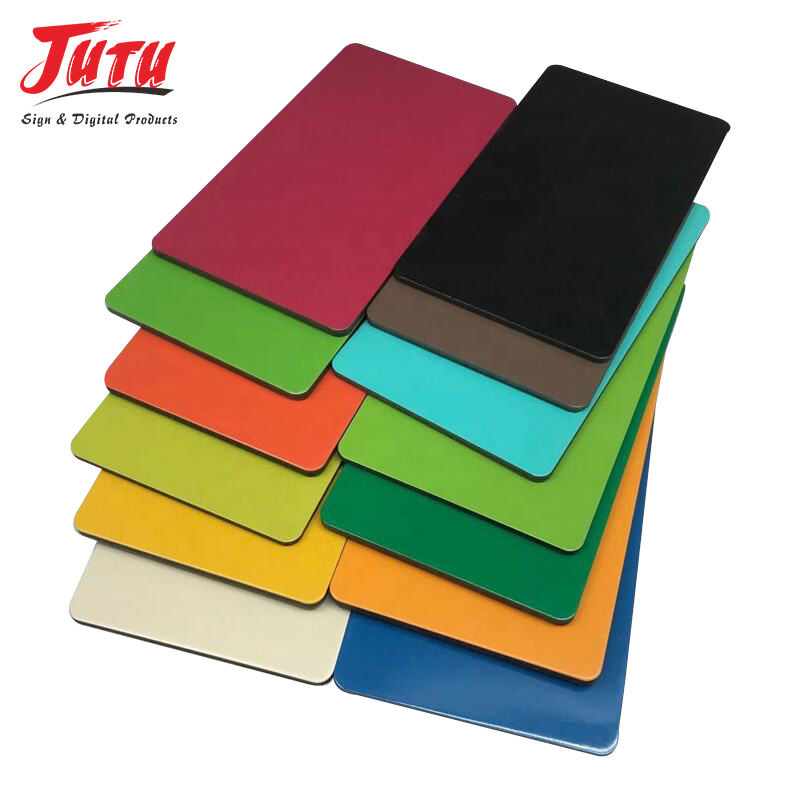

The aluminium polyethylene composite panel offers unparalleled design flexibility that enables architects and designers to realize complex architectural visions with remarkable ease and precision. Fabrication capabilities include precise cutting, routing, bending, and forming operations that create intricate geometric patterns and three-dimensional facade elements impossible to achieve with traditional materials. The panel's composition allows for tight radius bending without cracking or delamination, enabling curved surfaces, cylindrical forms, and flowing architectural transitions that enhance building aesthetics. Color matching systems provide unlimited customization options through digital printing technologies, metallic finishes, wood grain textures, and stone-like appearances that replicate natural materials at a fraction of the cost. The aluminium polyethylene composite panel accepts various surface treatments including brushed finishes, mirror polishes, and textured patterns that create visual depth and architectural interest. Perforation capabilities allow for integrated ventilation systems, lighting installations, and acoustic management solutions while maintaining structural integrity and weather protection. Panel joining methods include invisible fastening systems that create seamless facade appearances with continuous surface planes and uninterrupted design flows. Dimensional stability ensures that large-scale installations maintain precise alignment and consistent reveal patterns throughout the building's service life. The material's workability allows for on-site modifications and adjustments without specialized equipment, reducing installation complexity and construction delays. Architects can specify different panel thicknesses within the same project to create shadow lines, depth variations, and layered facade compositions. The aluminium polyethylene composite panel integrates effectively with glazing systems, creating harmonious building envelopes that balance transparency and opacity. Custom fabrication capabilities include complex corner details, curved transitions, and architectural features that would require multiple materials in traditional construction methods. Quality control measures ensure that color consistency and surface finish uniformity are maintained across all panels in large-scale projects, delivering professional results that meet demanding architectural standards.