alucobond aluminum composite panel

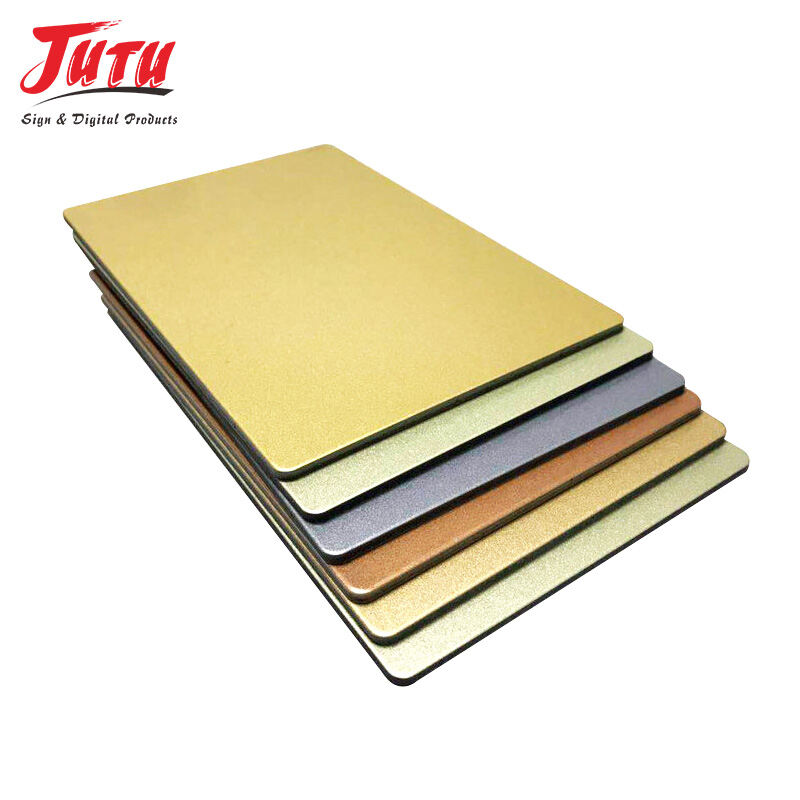

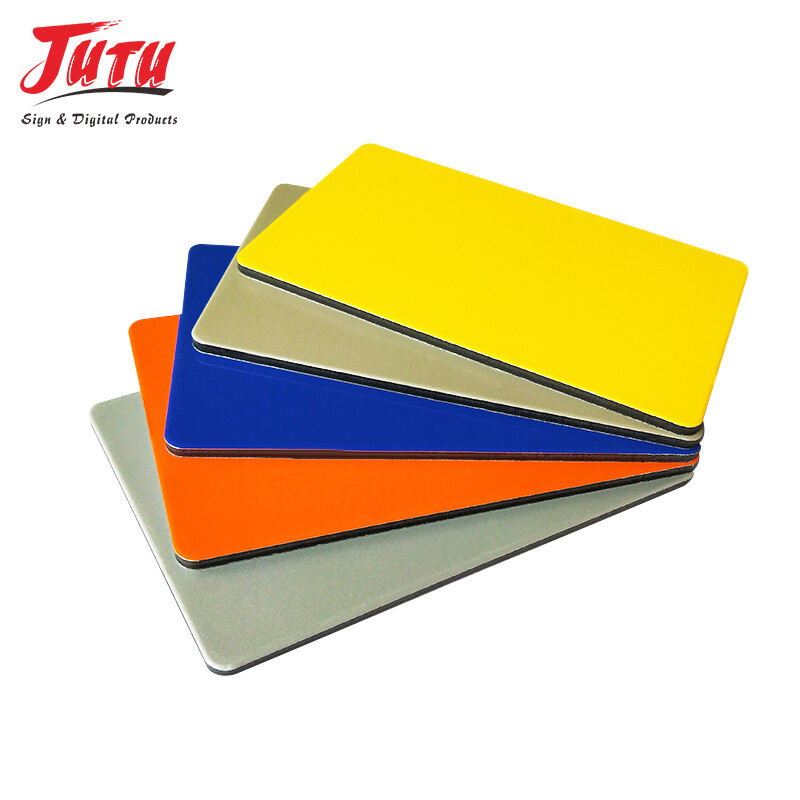

The alucobond aluminum composite panel represents a revolutionary building material that combines superior performance with exceptional versatility in modern construction applications. This advanced composite material consists of two thin aluminum sheets bonded to a non-aluminum core, creating a lightweight yet incredibly strong panel system that has transformed architectural design possibilities. The alucobond aluminum composite panel delivers outstanding structural integrity while maintaining remarkable flexibility for creative architectural expressions. Its sophisticated manufacturing process ensures consistent quality and dimensional stability, making it the preferred choice for architects and builders worldwide. The technological features of the alucobond aluminum composite panel include advanced fire-retardant properties, exceptional weather resistance, and superior thermal insulation capabilities. The panel's core material provides excellent sound dampening characteristics, reducing noise transmission in commercial and residential buildings. The alucobond aluminum composite panel maintains its structural properties across extreme temperature variations, from freezing conditions to intense heat exposure. Its surface treatments resist UV degradation, preventing color fading and material deterioration over extended periods. The applications for alucobond aluminum composite panel span across diverse construction sectors, including high-rise building facades, commercial storefronts, industrial facilities, and residential exterior cladding. Interior applications include partition walls, ceiling systems, and decorative elements in hotels, offices, and retail spaces. The alucobond aluminum composite panel excels in renovation projects where weight considerations are critical, as its lightweight nature reduces structural load requirements. Transportation infrastructure projects utilize these panels for tunnel linings, bridge coverings, and station facades due to their durability and low maintenance requirements.