Versatile Design Flexibility and Aesthetic Options

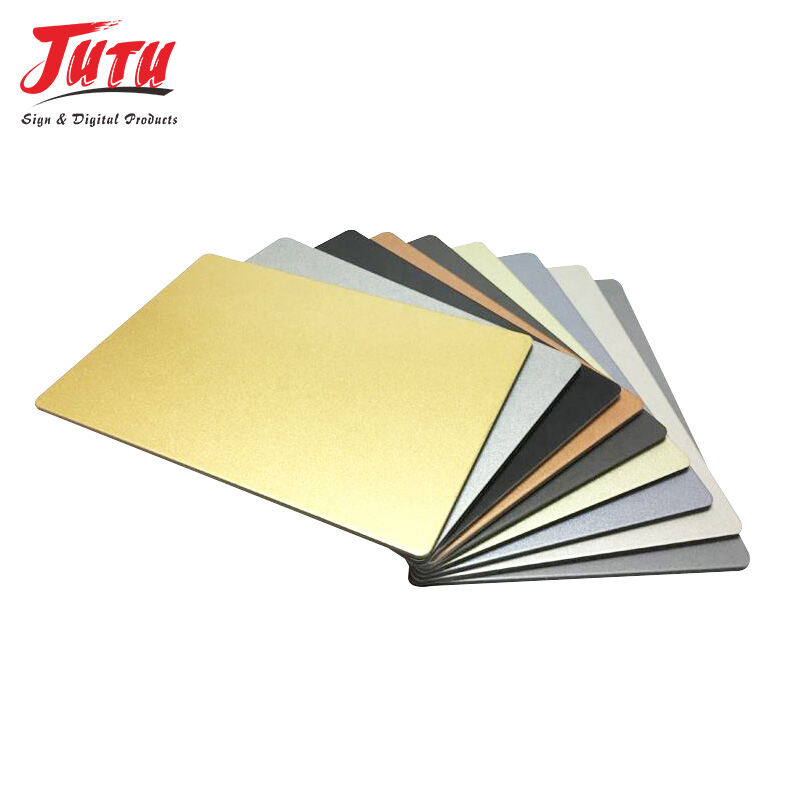

Aluminium panel sheet provides unparalleled design flexibility through its exceptional formability, extensive finishing options, and compatibility with diverse fabrication techniques that enable creative architectural solutions and functional applications across multiple industries. The inherent malleability of aluminium allows aluminium panel sheet to be formed into complex curves, sharp angles, and intricate shapes using standard metalworking equipment without cracking, tearing, or compromising structural integrity. This formability advantage enables designers to realize ambitious architectural visions that would be impossible or prohibitively expensive with less flexible materials. Advanced forming techniques including roll forming, brake forming, and stretch forming can produce precise geometries with tight tolerances that meet demanding aesthetic and functional requirements. The surface of aluminium panel sheet accepts numerous finishing treatments that dramatically expand color, texture, and appearance options while providing additional protective benefits. Anodizing processes create durable, integral color finishes that penetrate the aluminium surface to provide fade-resistant colors ranging from natural silver to bold architectural hues. Powder coating applications offer virtually unlimited color options with superior durability and weather resistance properties that maintain appearance integrity for decades under normal exposure conditions. Laminated finishes including wood grain, stone textures, and metallic patterns provide realistic aesthetic alternatives that combine the performance advantages of aluminium panel sheet with the visual appeal of premium natural materials. Fabrication versatility allows aluminium panel sheet to be cut, drilled, welded, and joined using standard tools and techniques without requiring specialized equipment or extensive operator training. The material's compatibility with mechanical fasteners, adhesives, and various welding processes provides designers with multiple assembly options that optimize performance, appearance, and cost considerations for specific applications. Perforation patterns, embossed textures, and custom forming operations can create unique visual effects and functional characteristics that distinguish projects while maintaining the fundamental performance advantages of aluminium panel sheet construction. Digital manufacturing technologies including laser cutting and CNC machining enable precise customization and rapid prototyping capabilities that support innovative design development and efficient production workflows for both standard and specialized applications requiring unique specifications or limited production quantities.