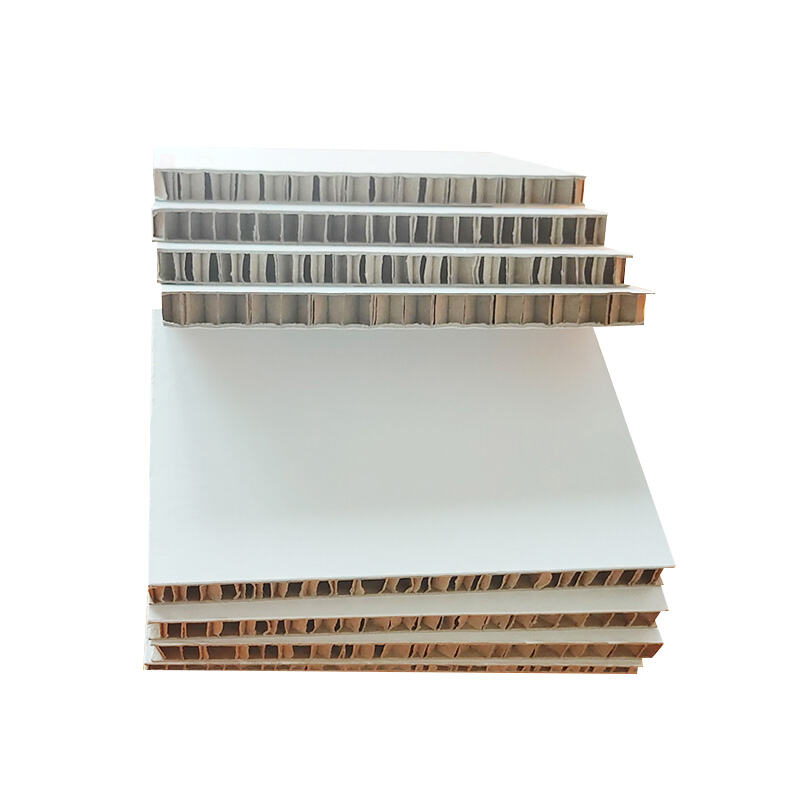

paper honeycomb wall panels

Paper honeycomb wall panels represent an innovative construction material that combines sustainability with exceptional performance characteristics. These panels feature a unique honeycomb core structure sandwiched between two outer layers, creating a lightweight yet remarkably strong building component. The honeycomb core consists of recycled paper materials arranged in hexagonal cells, mimicking the natural efficiency found in bee hives. This geometric configuration provides optimal strength-to-weight ratios while maintaining cost-effectiveness. Paper honeycomb wall panels serve multiple functions in modern construction projects, including interior partitioning, exterior cladding, and decorative applications. The technological features of these panels include superior sound absorption properties, excellent thermal insulation capabilities, and impressive structural integrity despite their minimal weight. Manufacturing processes utilize advanced adhesive bonding techniques to ensure durability and longevity in various environmental conditions. These panels demonstrate remarkable versatility in architectural applications, from residential homes to commercial office buildings, retail spaces, and institutional facilities. The cellular structure of paper honeycomb wall panels enables efficient material usage while reducing overall construction costs. Installation procedures are streamlined due to the panels' manageable weight and standardized dimensions, allowing for faster project completion times. Fire resistance properties can be enhanced through specialized treatments, making paper honeycomb wall panels suitable for applications requiring specific safety standards. Environmental considerations play a crucial role in their appeal, as these panels utilize recycled content and contribute to sustainable building practices. Quality control measures ensure consistent performance across different production batches, while customization options allow architects and designers to specify dimensions, surface finishes, and performance characteristics according to project requirements.