Exceptional Versatility and Application Range

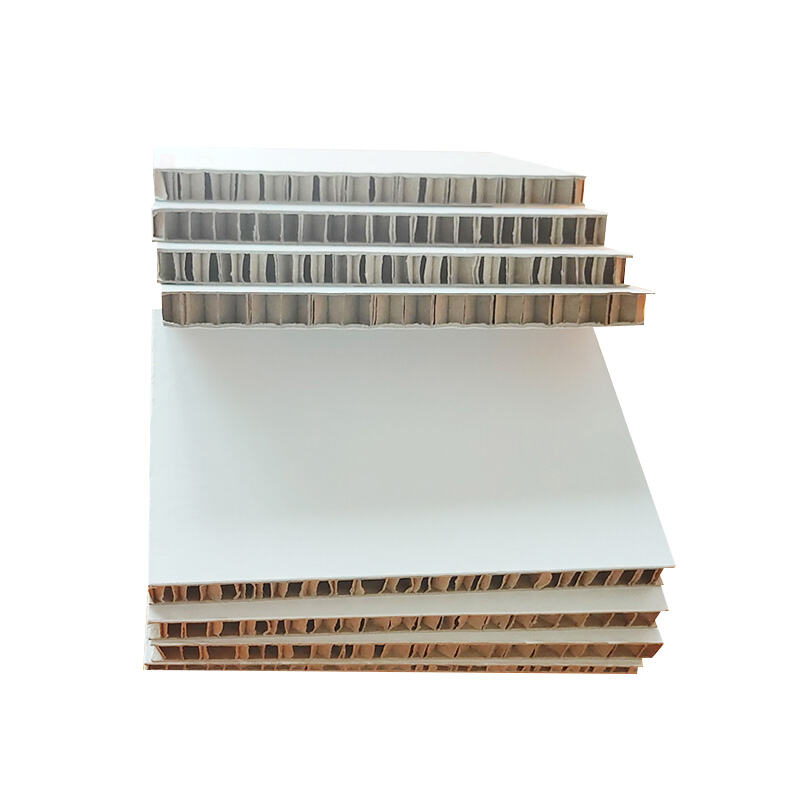

The remarkable adaptability of honeycomb particle board enables its use across an unprecedented range of applications, from precision furniture components to large-scale architectural installations. This versatility stems from the material's unique combination of lightweight construction, structural strength, and excellent machinability using standard woodworking equipment. Furniture manufacturers particularly value the material's consistent thickness and surface quality, which eliminate the sorting and preparation steps required with natural wood products. The particle board faces accept all common finishing materials including laminates, veneers, paints, and stains, allowing designers complete creative freedom in achieving desired aesthetic outcomes. Custom thickness options accommodate specific application requirements, from thin panels for cabinet doors to thick structural components for heavy-duty applications. The material machines cleanly with standard carbide-tipped tools, producing smooth edges that require minimal finishing preparation. Complex shapes and cutouts are easily achieved using CNC equipment, enabling intricate designs previously difficult or expensive to produce with solid materials. Architectural applications benefit from the material's excellent flatness and dimensional stability, crucial for achieving professional installation results in wall panels and ceiling systems. The honeycomb particle board accepts various joining methods including mechanical fasteners, adhesives, and specialized hardware systems, providing flexibility in assembly techniques. Specialized versions can be manufactured with enhanced fire resistance, moisture protection, or acoustic properties to meet specific building code requirements. The material's thermal insulation properties make it valuable for applications requiring energy efficiency, such as refrigerated displays and insulated doors. Transportation industries utilize honeycomb particle board for interior panels, flooring, and partition systems where weight reduction directly improves fuel efficiency and payload capacity. Exhibition and retail display applications benefit from the material's light weight for portable structures and its excellent surface finish for high-quality appearance requirements. Quality grades range from utility applications to premium furniture components, ensuring cost-effective solutions for every performance requirement level.