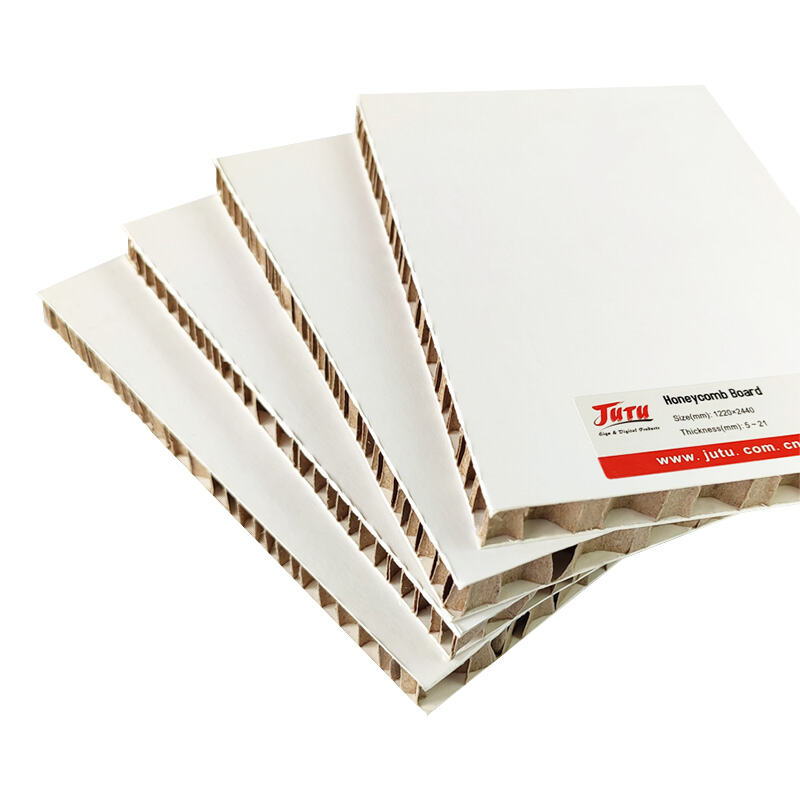

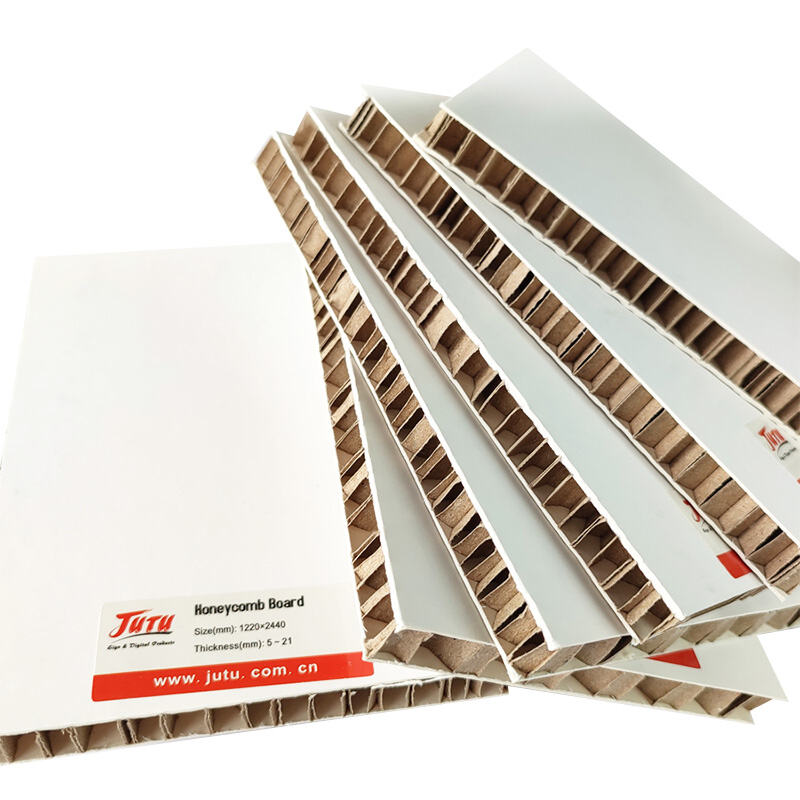

honeycomb core board

Honeycomb core board represents a revolutionary advancement in composite material technology, featuring a distinctive hexagonal cell structure that delivers exceptional performance across diverse industrial applications. This innovative material consists of a lightweight honeycomb core sandwiched between two outer face sheets, creating a composite panel that maximizes strength while minimizing weight. The honeycomb core board structure mimics nature's most efficient design, utilizing the geometric properties of hexagonal cells to achieve optimal load distribution and structural integrity. Manufacturing processes involve bonding aluminum, aramid, or thermoplastic honeycomb cores to various face materials including aluminum, fiberglass, carbon fiber, or specialized laminates. The resulting honeycomb core board exhibits remarkable mechanical properties that surpass traditional solid materials in strength-to-weight ratios. Primary functions include structural support, insulation, vibration dampening, and impact resistance across aerospace, marine, construction, and transportation sectors. Technological features encompass customizable cell sizes, adjustable core densities, and variable face sheet materials to meet specific performance requirements. The honeycomb core board design enables manufacturers to tailor properties such as compressive strength, shear modulus, and thermal conductivity based on application demands. Advanced manufacturing techniques ensure consistent quality and dimensional stability throughout production runs. Applications span from aircraft interior panels and satellite components to architectural facades and marine bulkheads. The honeycomb core board technology continues evolving with new materials and bonding methods, expanding possibilities for lightweight structural solutions. Environmental benefits include reduced material consumption and enhanced recyclability compared to solid alternatives, making honeycomb core board an increasingly popular choice for sustainable engineering projects.