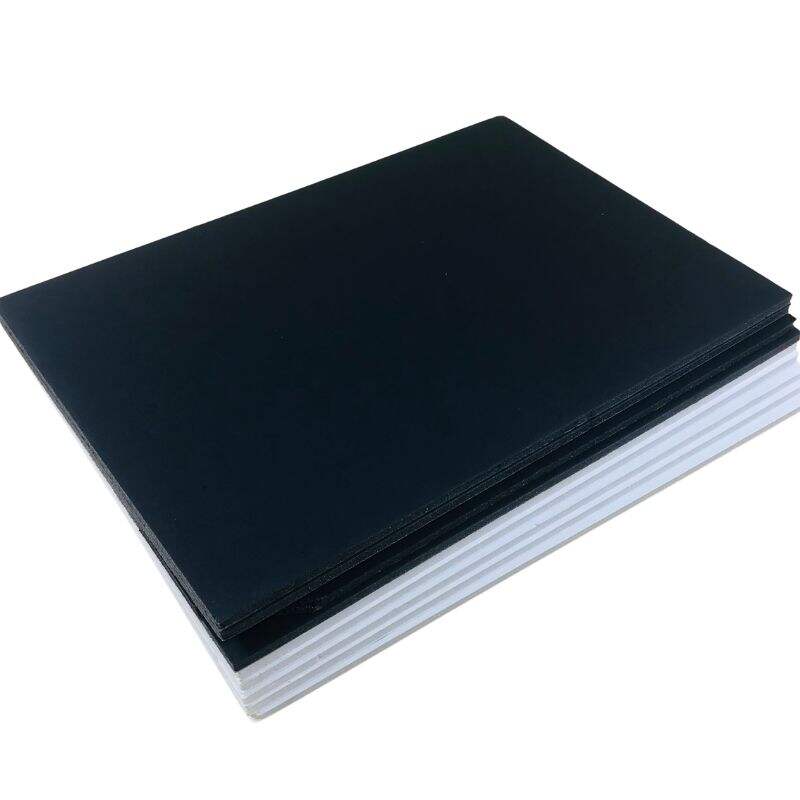

foam paper board manufacturer

A foam paper board manufacturer represents a specialized industrial enterprise that produces lightweight, versatile composite materials combining the benefits of traditional paperboard with expanded foam cores. These manufacturers utilize advanced production technologies to create multi-layered boards featuring paper facings bonded to foam substrates, resulting in materials that offer exceptional strength-to-weight ratios and thermal insulation properties. The foam paper board manufacturer operates sophisticated machinery that precisely controls foam density, paper adhesion, and board thickness to meet diverse industry specifications. Modern foam paper board manufacturers employ cutting-edge extrusion processes, where polystyrene or polyurethane foam cores are sandwiched between high-quality paper layers through heat-activated adhesives. This manufacturing process ensures consistent product quality while maintaining cost-effectiveness for large-scale production runs. The technological infrastructure of a foam paper board manufacturer typically includes computer-controlled cutting systems, precision laminating equipment, and quality control laboratories that monitor material properties throughout production cycles. These facilities often incorporate environmental management systems to minimize waste and optimize resource utilization. Leading foam paper board manufacturers invest heavily in research and development to enhance product performance characteristics, including moisture resistance, fire retardancy, and structural integrity. The manufacturing process involves careful selection of raw materials, where paper quality and foam composition directly impact final product performance. Quality foam paper board manufacturers maintain strict adherence to international standards and certifications, ensuring their products meet regulatory requirements across various applications. The production capabilities of established foam paper board manufacturers often include custom sizing, specialized coatings, and tailored density specifications to accommodate specific customer requirements and industry demands.