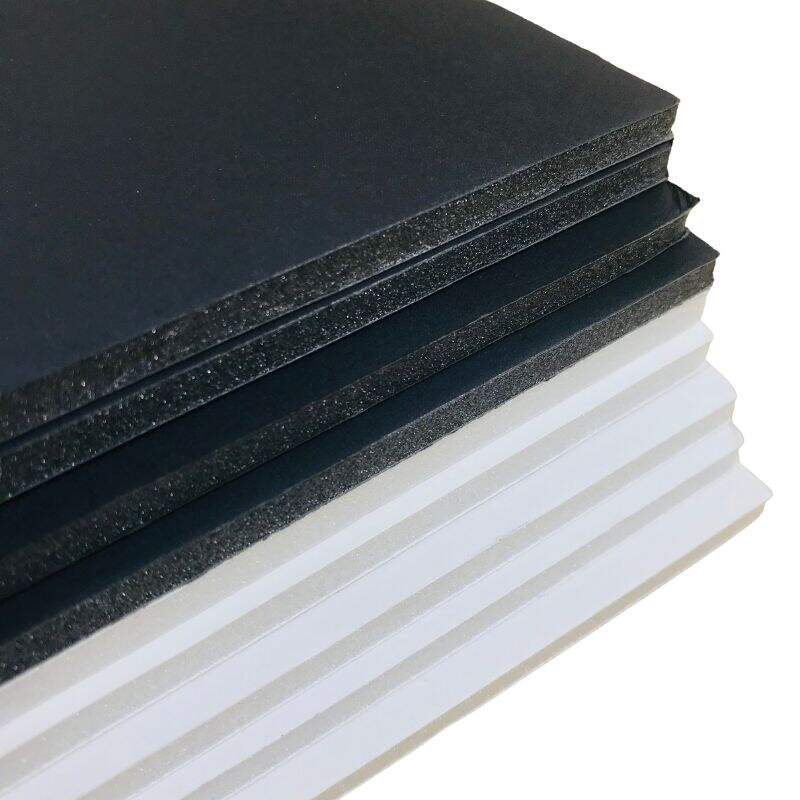

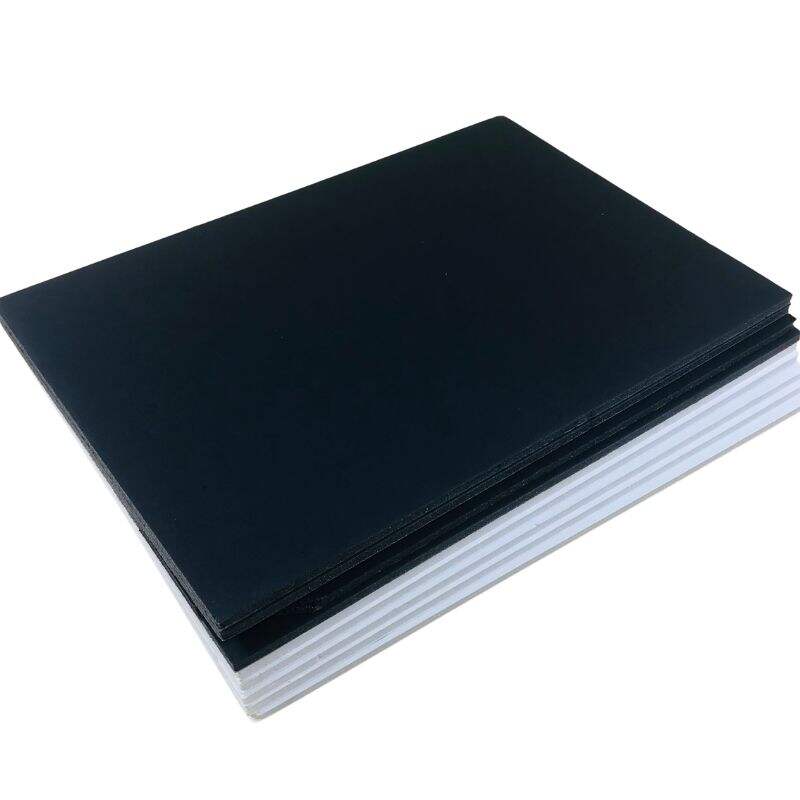

foam board paper manufacturer

A foam board paper manufacturer specializes in producing lightweight, versatile panels that combine the structural integrity of foam cores with the smooth, printable surfaces of paper lamination. These manufacturers utilize advanced production technologies to create rigid yet lightweight boards that serve multiple industries, from advertising and display to architectural modeling and packaging solutions. The foam board paper manufacturer employs sophisticated lamination processes that bond high-quality paper surfaces to expanded polystyrene or polyurethane foam cores, resulting in products that offer exceptional dimensional stability and superior print receptivity. Modern foam board paper manufacturer facilities incorporate precision cutting systems, automated lamination equipment, and quality control mechanisms that ensure consistent thickness, flatness, and adhesion across all products. The manufacturing process involves careful selection of foam densities, paper weights, and adhesive formulations to meet specific application requirements. These manufacturers serve creative professionals, architects, retailers, and educational institutions who require dependable materials for presentations, signage, and prototype development. The foam board paper manufacturer typically offers various thickness options, ranging from lightweight 3mm panels to robust 20mm boards, accommodating diverse structural and aesthetic needs. Production capabilities often include custom sizing, specialty coatings, and colored surfaces that expand design possibilities. Quality foam board paper manufacturer operations maintain strict environmental controls during production to prevent warping, delamination, or surface imperfections. These facilities invest in research and development to improve product durability, reduce environmental impact, and enhance printing compatibility. The foam board paper manufacturer sector continues evolving with sustainable materials, digital printing optimization, and specialized applications in retail displays, trade show exhibits, and temporary architectural installations. Strategic partnerships with distributors and end-users enable foam board paper manufacturer companies to provide technical support, custom solutions, and reliable supply chains that meet demanding project timelines and performance specifications across various market segments.